Optical fiber with ring-shaped doped layer and preparation method thereof and laser containing optical fiber

A fiber laser and doped layer technology, applied in clad fibers, multi-layer core/clad fibers, glass manufacturing equipment, etc., can solve the problem of increasing the pump absorption coefficient, reducing the laser damage threshold of the fiber end face, and reducing the purity of quartz and uniformity and other issues, to achieve the effect of mature preparation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

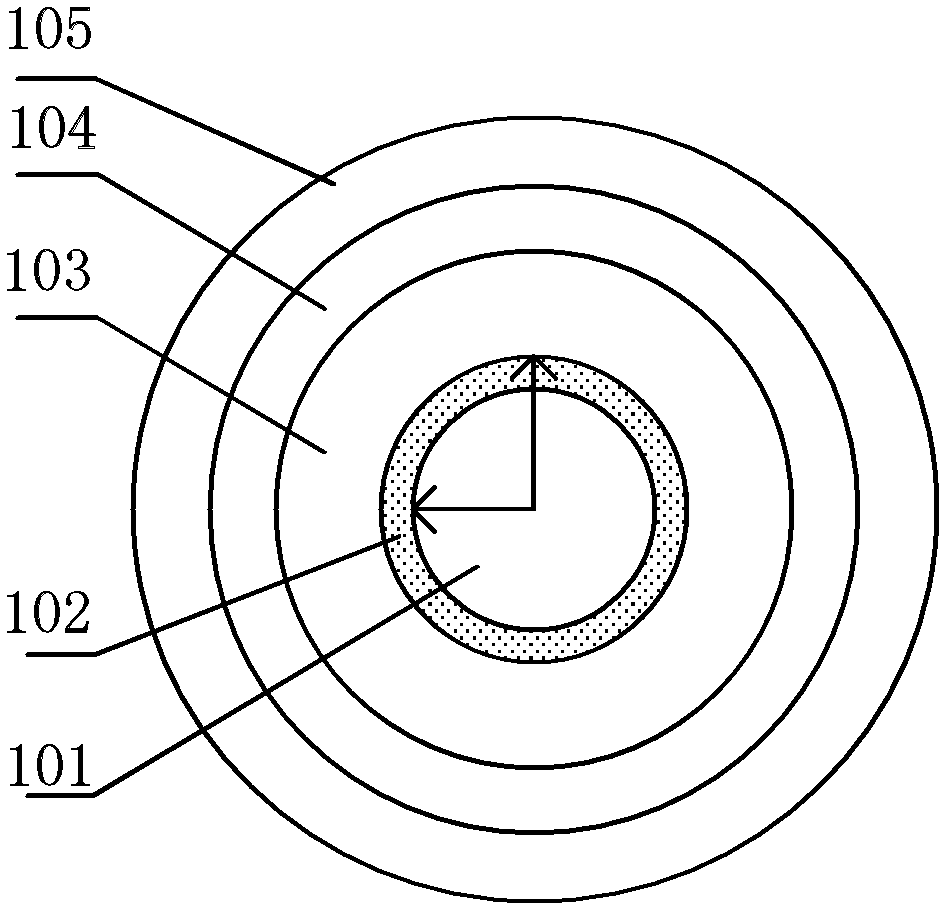

[0043] The annular doped layer optical fiber structure in this embodiment is as follows figure 1 As shown, it includes an inner cladding (undoped core) 101 , a ring-shaped doped layer 102 , a middle cladding 103 , an outer cladding 104 and a protective layer 105 .

[0044] The annular doped layer 102 is made of a matrix material doped with rare earth elements such as quartz glass or fluoride glass;

[0045] The material and refractive index of the inner cladding layer 101 and the middle cladding layer 103 are the same, and the material can be selected from a matrix material with a refractive index smaller than that of the annular doped layer, a lateral dimension and a numerical aperture larger than that of the annular doped layer, such as quartz glass or fluoride glass, etc. Preparation, the outer cladding layer 104 is made of a poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com