WLP (wafer level package) IRFPA (infrared focal plane array) device and manufacturing method thereof

A device manufacturing method and infrared focal plane technology, which are applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of unfavorable popularization and application of infrared focal plane array devices, low infrared absorption efficiency, complex manufacturing process, etc., and achieve high detection accuracy. , compact structure, the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific drawings and embodiments.

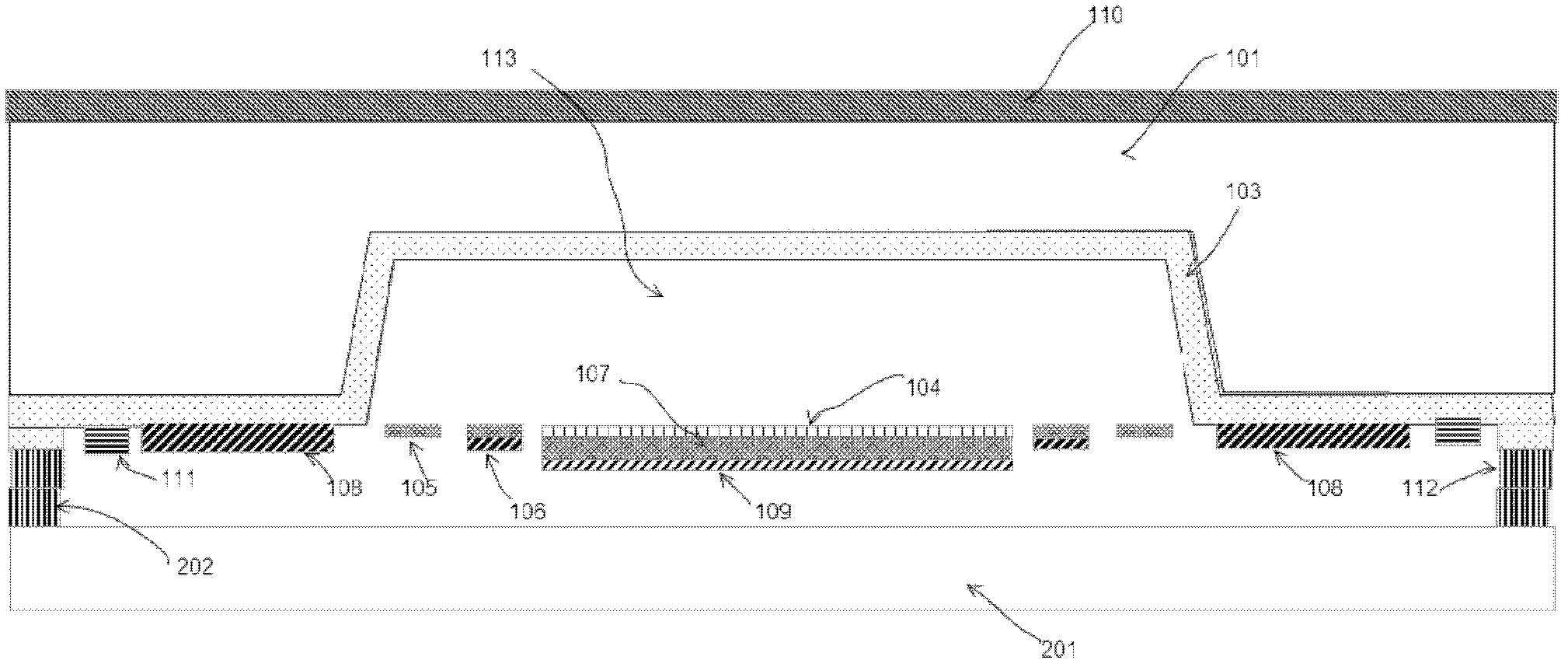

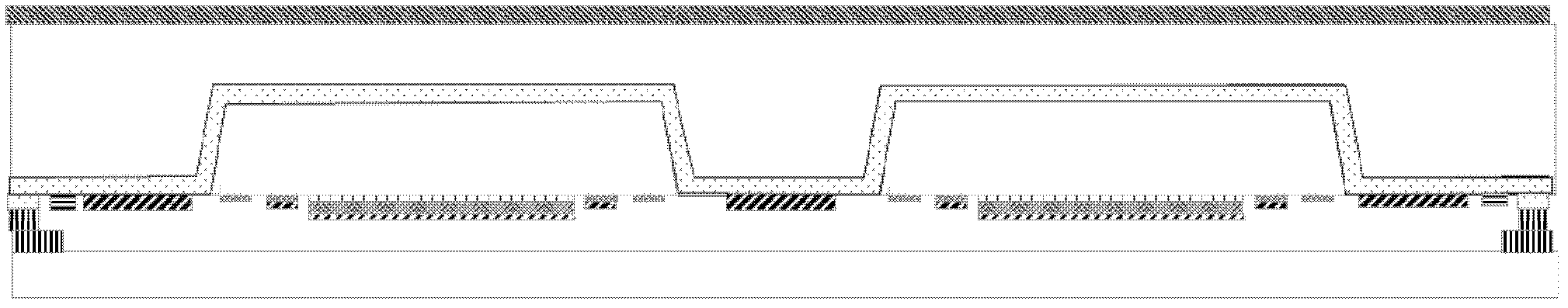

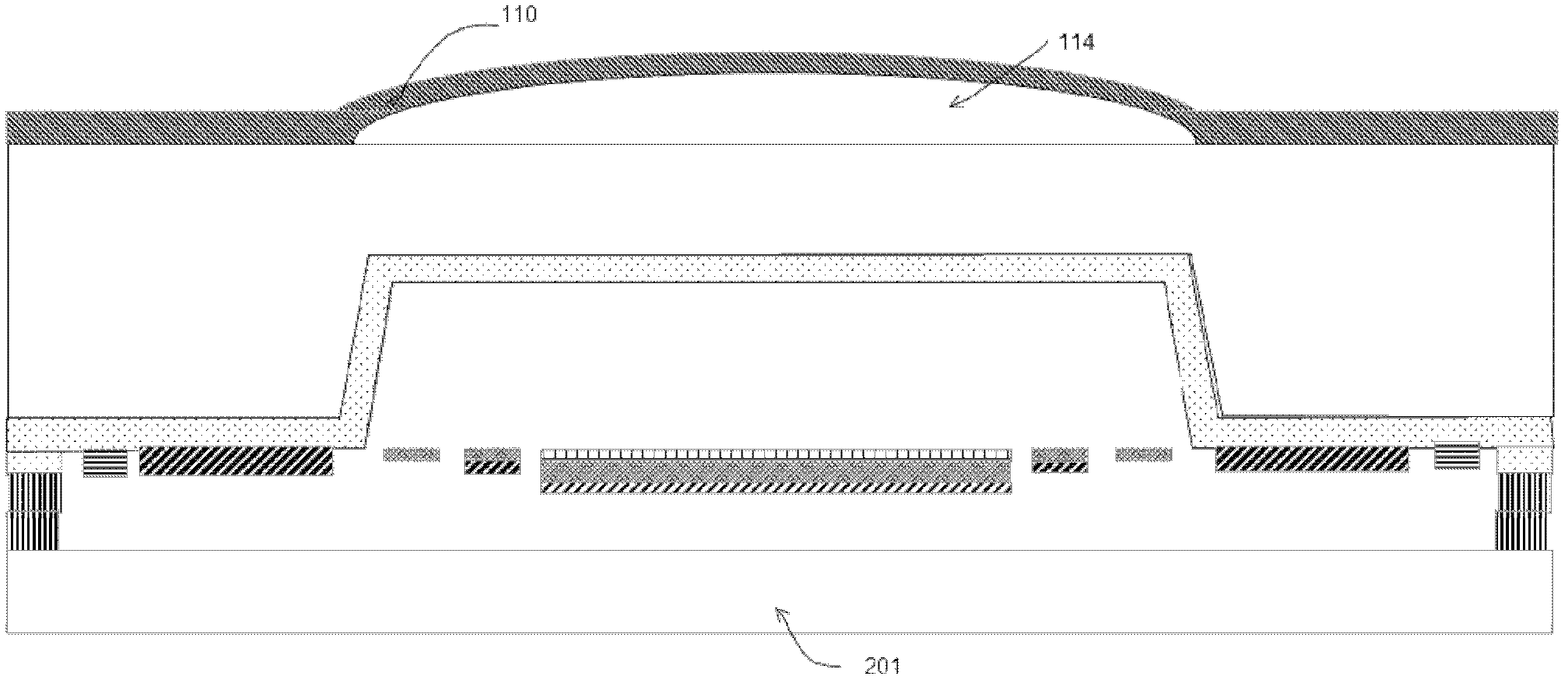

[0040] Such as Figure 1~Figure 10 As shown: the present invention includes a first substrate 101, a buried sacrificial layer 102, a process barrier layer 103, an infrared absorbing layer 104, an insulating beam 105, a deformable beam 106, a refractive medium layer 107, a heat dissipation frame body 108, a reflective layer 109, Antireflection layer 110 , getter 111 , first substrate solder 112 , cavity 113 , microlens 114 , second substrate 201 and second substrate solder 202 .

[0041] Such as figure 1 and Figure 10 As shown: the present invention includes a first substrate 101 and a second substrate 201 located below the first substrate 101, the material of the first substrate 101 includes single crystal silicon, Ge, GaAs or GeSi; the first substrate 101 is concavely provided with grooves, figure 1 and Figure 10 shows a schematic structural diagram o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com