Treating agent as well as method and device for continuously reducing hydrogen sulfide in oil well shaft

A technology of treating agent and hydrogen sulfide, which is applied in wellbore/well components, earthwork drilling and production of fluids, etc., can solve the problems of waste, ineffectiveness, and less addition, and achieve the effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The treatment agent of this embodiment consists of: 38% industrial paraffin; 50% calcium hypochlorite; and 12% sodium carbonate.

[0057] According to the above ratio, heat the industrial paraffin to a molten state, then slowly add sodium carbonate and calcium hypochlorite, stir evenly, pour into a cylindrical mold, and cool to obtain a solid product. The diameter of the wax block is the same as the inner diameter of ordinary 3-inch tubing.

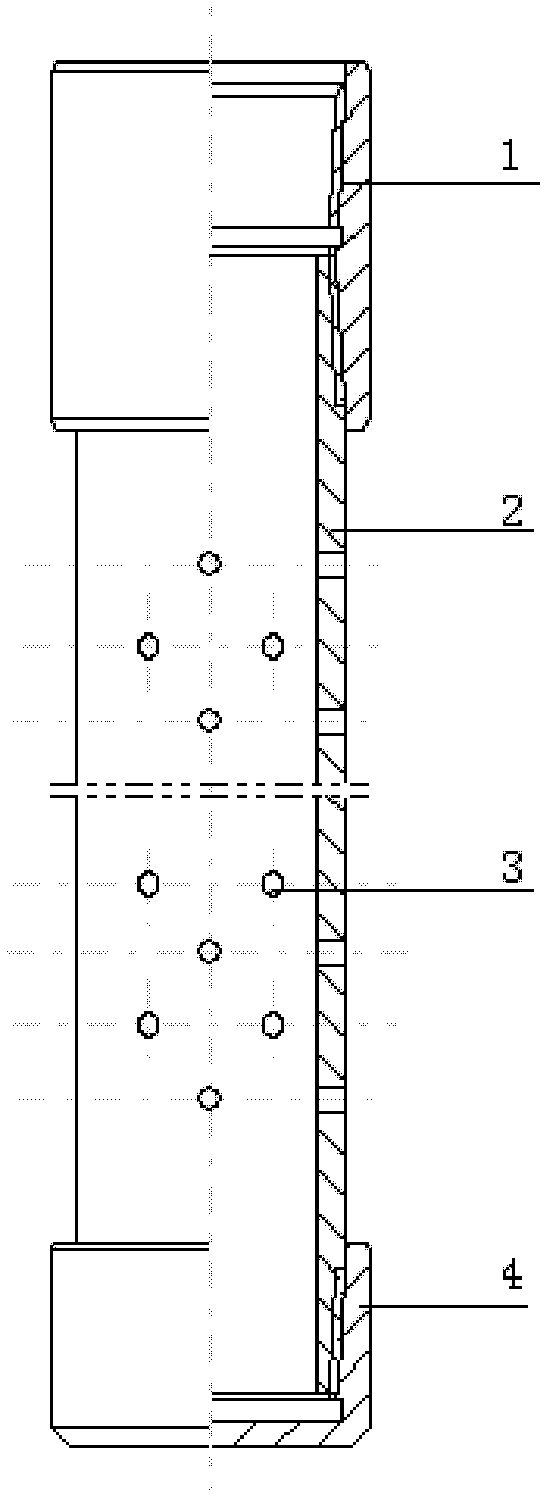

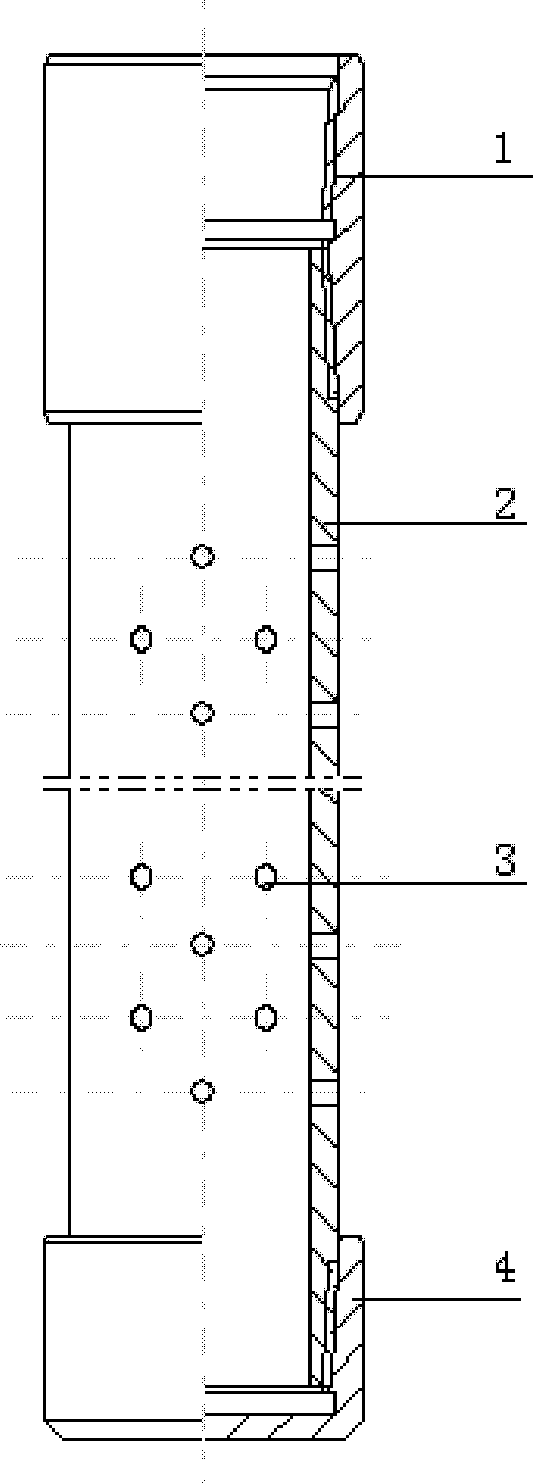

[0058] Use 10 meters of ordinary 3-inch oil pipe as the container body 2 for accommodating the treatment agent, set couplings 1 at both ends, and leave about 150mm from the couplings (about 150mm long) at both ends, and drill 6 holes with a diameter of 6mm symmetrically according to the circumference The through holes 3 of the pipe string are arranged in a triangle with a hole distance of 50mm along the straight line direction of the pipe string (see figure 1 ), the inside packs the cylindrical treating agent wax block of the pres...

Embodiment 2

[0063] The composition of the treatment agent in this embodiment: 30% industrial paraffin; 10% polyethylene wax; 50% calcium hypochlorite; and 10% sodium hydroxide.

[0064] According to the above ratio, industrial paraffin and polyethylene wax are heated to a molten state, then slowly add sodium carbonate and calcium hypochlorite, after stirring evenly, pour into a spherical mold and cool to obtain a solid treatment agent wax ball product (wax ball diameter 6mm ).

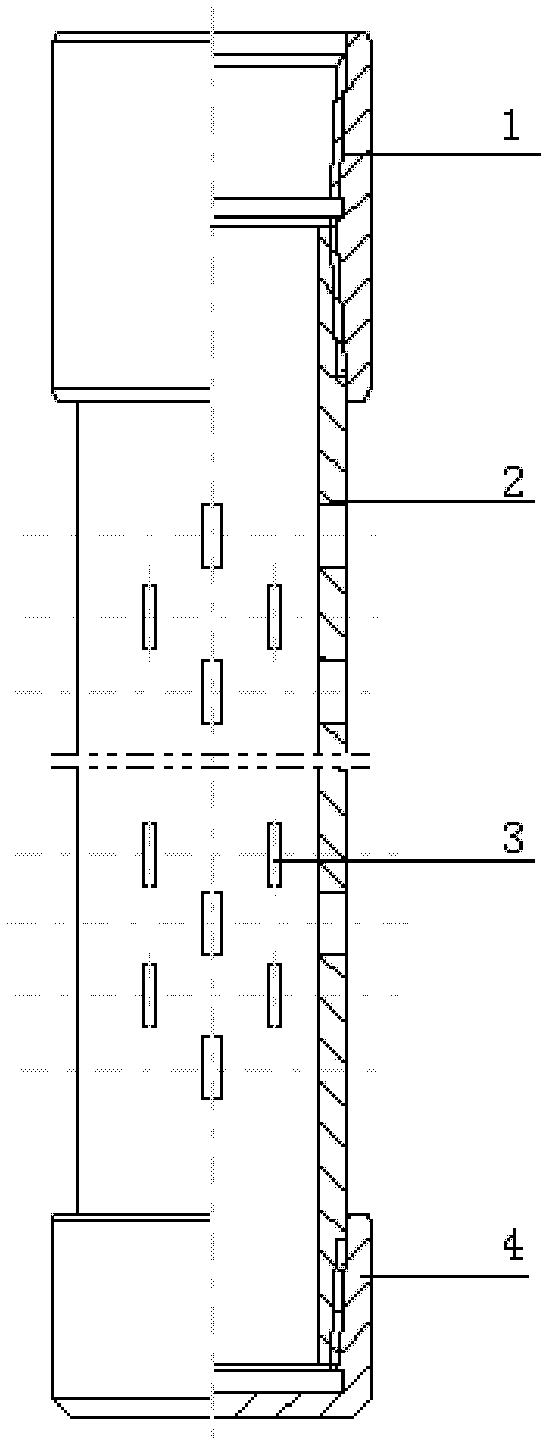

[0065] 10 meters of ordinary 3-inch oil pipe is used as the container body 2 for accommodating the treatment agent, and the two ends are provided with couplings 1, and the two ends are respectively set aside about 150mm from the coupling (150mm in length), and the laser cutting technology is adopted according to the circumferential symmetry. Cut out long slit-shaped through-holes 3 with a length of 10mm and a width of 2mm, 6 through-holes in a circle, and a slit distance of 20mm along the straight line of the pipe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com