Energy dissipation method of sidewall aeration steps and outlet submerged flip bucket of inclined shaft type flood discharge tunnel

A technology for aeration sills and flood discharge tunnels, which is applied in water conservancy projects, marine engineering, coastline protection, etc., can solve problems such as landslides and environmental degradation, short-circuiting of high-voltage transformers, and damage to shore roads, etc. Energy dissipation rate, improve the effect of energy dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

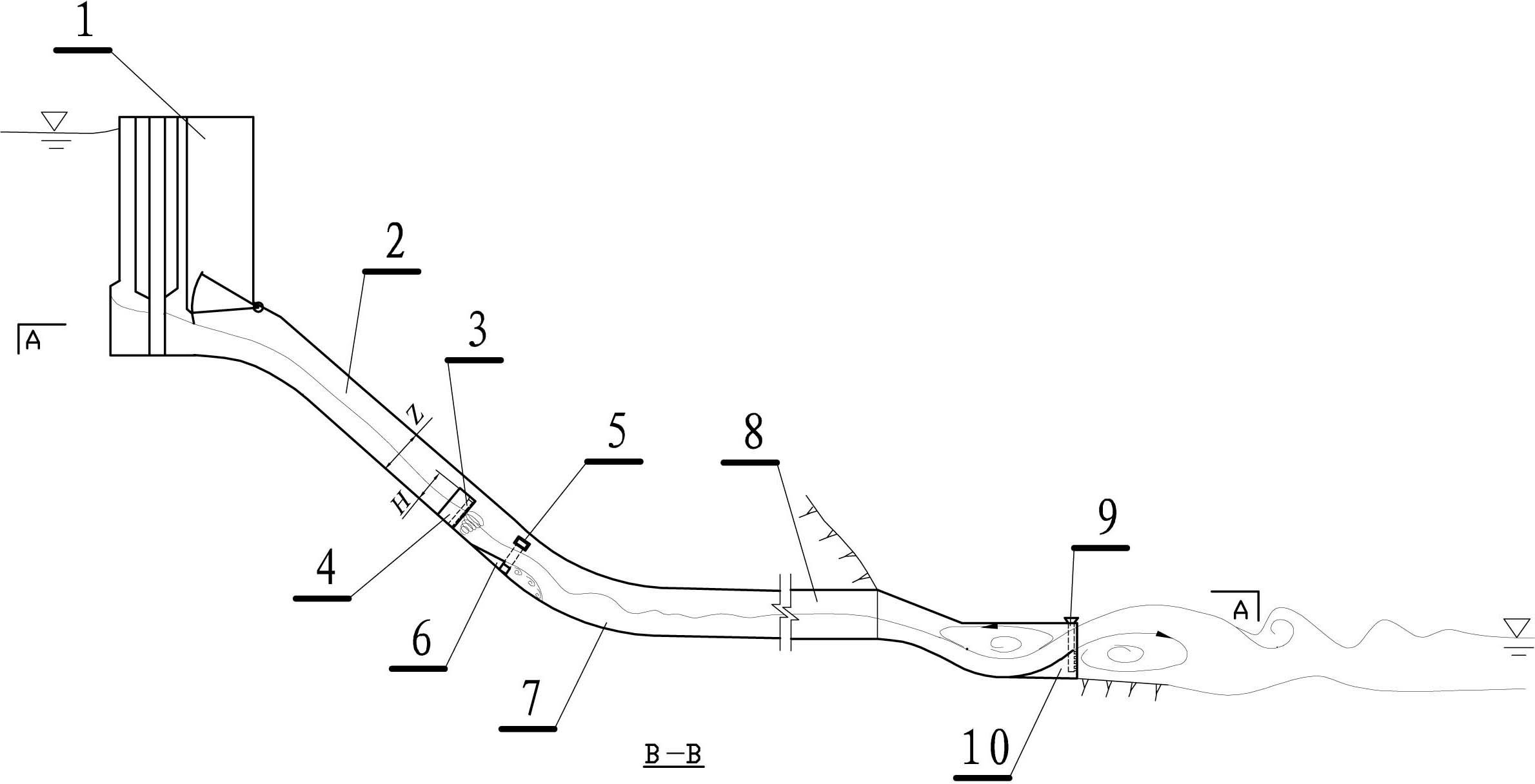

[0021] This embodiment is an energy dissipator for the side wall aeration sill and the outlet diving deflector sill of an inclined shaft type flood discharge tunnel, such as figure 1 , 2 shown. The inclined well type flood discharge tunnel described in this embodiment includes: a water inlet 1, the water inlet is connected to the inclined well 2, the inclined well is connected to the water outlet hole 8, and the reverse arc connecting the inclined well to the water outlet hole The bottom plate at the beginning of the section 7 is provided with a main aeration sill 6 with a vent pipe 5, and a pair of side aeration chambers with a vent pipe 3 are arranged opposite to each other on the two side walls of the upstream of the main aeration sill. Air barrier 4. The position of the outlet of the outlet hole is set below the flood water level of the river, the angle between the outlet of the outlet hole and the water flow of the river is less than 90 degrees and expands along the dir...

Embodiment 2

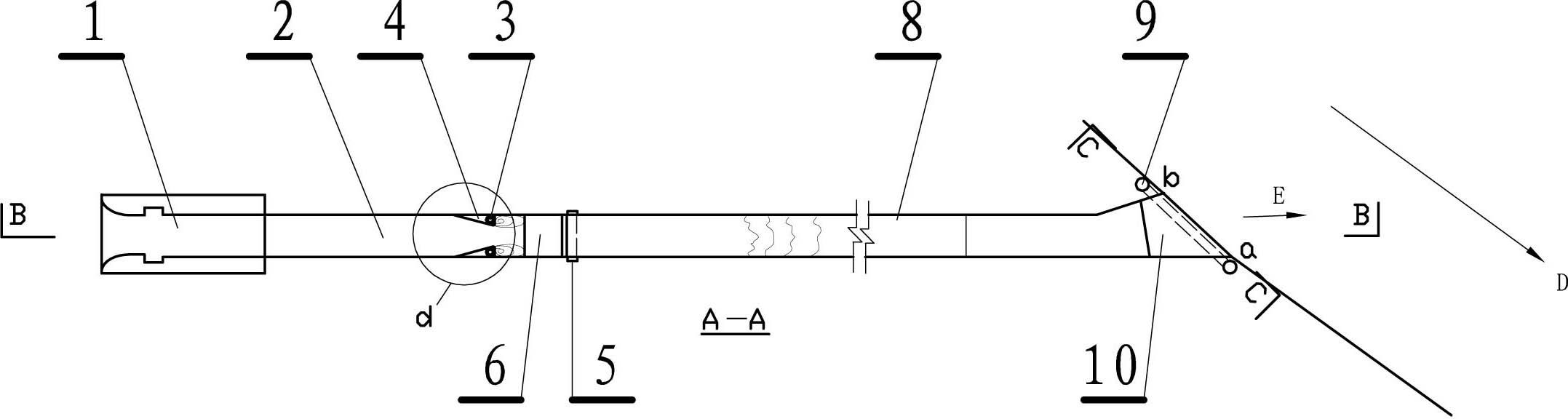

[0029] This embodiment is an improvement described in Embodiment 1, and it is a refinement of the side air-entrainment sill described in Embodiment 1, such as image 3 , 4 shown. The ventilation pipe of the side aeration sill described in this embodiment consists of a main pipe 301 and a branch pipe 302 connected to the main pipe. The air inlet of the main pipe is arranged on the top of the side aeration sill, and the air outlet of the branch pipe is arranged On the backside of the side aeration ridge. The protruding angle α of the side aeration sill is less than or equal to 15 degrees. The flow area between the two side aeration sills is not less than 0.65 times the cross-sectional area of the inclined well.

[0030] The cross-sectional shape of the side aeration sill described in this embodiment is a triangular cross-section, and the height from the bottom plate H Should meet 0.7 Z H Z condition( Z - section height of the inclined shaft, see figure 1 ), H It shal...

Embodiment 3

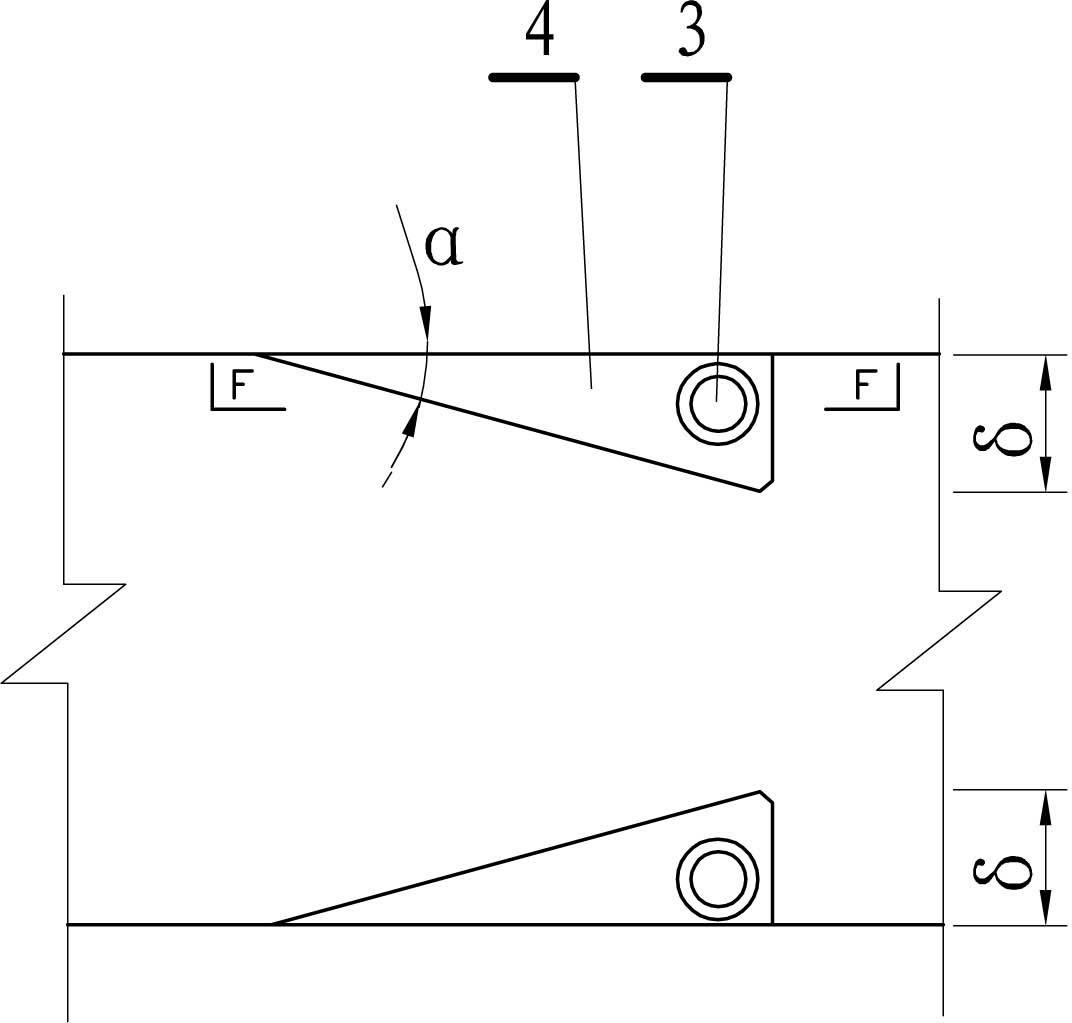

[0032] This embodiment is an improvement of the above-mentioned embodiment, and it is a refinement of the above-mentioned embodiment about the diving sill, such as Figure 5 , 6 mentioned. The ventilation pipe of the diving sill described in this embodiment is connected along the back water surface of the diving sill, and the air inlet 901 of the ventilation pipe is arranged above the highest flood water level of the river channel, and is placed on the diving sill. A plurality of air outlets 902 are evenly arranged on the backside of the ridge.

[0033] The diving sill described in this embodiment is poured below the downstream design flood level, while the traditional sill is poured above the downstream checked flood level. The sill height of the diving sill described in the present embodiment is also changed along the flow direction of the river channel, from the low sill b straight line to the high sill a (see Figure 5 ), but the corresponding shooting angle β is smalle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com