Polymer clay stabilizer containing Beta-cyclodextrin structure and synthesis method thereof

A clay stabilizer and polymer technology, applied in the field of polymer clay stabilizer and its synthesis, can solve the problems of inability to produce multi-point adsorption, resistance to erosion, formation transformation, etc., and achieve rigidity enhancement, viscosity increase, and inhibition of hydration. inflated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: the preparation of XBH monomer

[0021] Add 100ml of deionized water and 1.5g of sodium hydroxide to a single-necked flask to make a 1.5% alkaline solution. After cooling down, add 34.05g (0.03mol) of β-cyclodextrin and stir until clear, then add 3.4242g dropwise at room temperature (0.03mol) AGE, 5 minutes to drop, react for 7 hours, after the reaction, neutralize with 85% phosphoric acid, filter under reduced pressure to remove unreacted β-cyclodextrin, dissolve the filtrate in ethanol, and centrifuge to separate the salt, The supernatant was distilled under reduced pressure to obtain light yellow viscous liquid XBH.

Embodiment 2

[0022] Embodiment 2: Synthesis of AM / NaAA / AMPS / XBH tetrapolymer

[0023] First weigh AA and AMPS according to the ratio in Table 1, put them into a 250mL jar and dissolve them with distilled water, cool to room temperature, add AM and XBH, and dissolve them completely at room temperature, adjust the pH to 7 with NaOH solution, and blow nitrogen After 20 minutes, add the pre-prepared sodium bisulfite solution, stir for 5 minutes, add ammonium persulfate solution, continue to pass nitrogen gas for 10 minutes, and seal the reaction at a constant temperature of 35°C for 8 hours. Precipitate with absolute ethanol, crush the precipitate into particles, soak in absolute ethanol and dry at 40°C for 2 days to obtain AM / NaAA / AMPS / XBH tetrapolymer.

[0024] Table 1 Quaternary polymer synthesis drug dosage

[0025]

Embodiment 3

[0026] Embodiment 3: AM / NaAA / AMPS / XBH tetrapolymer structure characterization

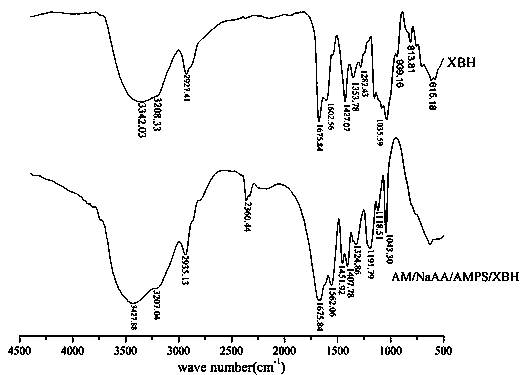

[0027] The infrared spectrograms of monomer XBH and tetrapolymer AM / NaAA / AMPS / XBH synthesized by embodiments 1 and 2 are as follows figure 1shown. In the monomer XBH spectrum, 3342.03cm -1 -OH stretching vibration peak at 1675.84cm -1 and 1602.56cm -1 It is the characteristic peak of -C=C-, 1427.07cm -1 、1353.78cm -1 、1282.43cm -1 is the characteristic peak of β-cyclodextrin ring, 1151.29cm -1 、1081.87cm -1 and 1035.59cm -1 is the characteristic peak of ether bond. From the polymer spectrum in the figure, –OH and –NH 2 The stretching vibration peak is at 3427.88cm -1 (compared with 3342.03 in XBH, the peak is broadened, so –OH and –NH 2 overlap), –C=O stretching vibration peak at 1675.84cm -1 ,1451.92cm -1 、1407.78cm -1 and 1324.86cm -1 is the characteristic peak of β-cyclodextrin ring, –SO 3 - Stretching vibration peak at 1191.79cm -1 place.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com