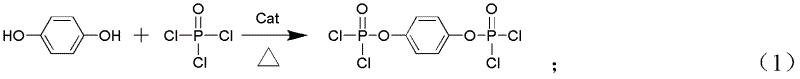

Method for preparing organic phosphorous flame retardant with hydroquinone phosphate as framework

A technology of hydroquinone phosphate and quinone phosphate, which is applied in the field of preparation of organophosphorus flame retardants, can solve the problems of synthetic process description, unsuitability for industrial production, high cost, etc., and achieve environmental friendliness and high product quality. High purity, convenient transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The first step is the synthesis of hydroquinone phosphate intermediate (1): add 27.5g (0.25mol) hydroquinone into a four-necked flask equipped with stirring, condensing device, temperature probe and protective gas interface, and the temperature is controlled at 80°C , add 116ml (1.25mol) phosphorus oxychloride (POCl 3 ), adding 1.0g (0.0075mol) of aluminum trichloride as a catalyst, reacting at this temperature for 3h, and absorbing the hydrogen chloride gas produced by dilute lye. Distill unreacted POCl under reduced pressure 3 , to obtain 83.9 g (0.245 mol) of hydroquinone phosphate intermediate (1), with a yield of 98%.

[0037]The second step of product synthesis: Take 112g (1.19mol) of phenol and add it to the same type of flask as above, add 1.0g (0.0075mol) of aluminum trichloride as a catalyst, control the reaction temperature at 100°C, and add hydroquinone phosphate in 3 times The intermediate (1) was added into the reaction flask and reacted for 6-8 hours. ...

Embodiment 2

[0041] The first step is the synthesis of hydroquinone phosphate intermediate (1): Add 27.5g (0.25mol) hydroquinone into a four-necked flask with stirring, condensing device, temperature probe and protective gas connection, and control the temperature at 100°C , add 93ml (1.03mol) phosphorus oxychloride (POCl 3 ), adding 1.0g (0.0075mol) of aluminum trichloride as a catalyst, reacting at this temperature for 2h, and absorbing the hydrogen chloride gas produced by dilute lye. Distill unreacted POCl under reduced pressure 3 , to obtain 84.1 g (0.245 mol) of hydroquinone phosphate intermediate (1), with a yield of 98%.

[0042] The second step of product synthesis: Take 42g (0.56mol) of tert-butanol and add it to the above-mentioned four-necked flask of the same type, add 1.0g (0.0038mol) of tin tetrachloride as a catalyst, control the reaction temperature at 80°C, and divide the p-benzene Add the diphenol phosphate intermediate (1) into the reaction flask, and react for 6 hour...

Embodiment 3

[0046] The first step is the synthesis of hydroquinone phosphate intermediate (1): add 27.5g (0.25mol) hydroquinone into a four-necked flask equipped with stirring, condensing device, temperature probe and protective gas interface, and the temperature is controlled at 60°C , add 116ml (1.25mol) phosphorus oxychloride (POCl 3 ), adding 1.5g (0.011mol) of aluminum trichloride as a catalyst, reacting at this temperature for 4h, and absorbing the hydrogen chloride gas produced by dilute lye. Distill unreacted POCl under reduced pressure 3 , to obtain 83.5 g (0.243 mol) of hydroquinone phosphate intermediate (1), with a yield of 97%.

[0047] The second step of product synthesis: Take 60g (0.60mol) of cyclohexanol and add it to the above-mentioned four-necked flask of the same type, add 1.0g (0.0075mol) of aluminum trichloride as a catalyst, control the reaction temperature at 100°C, and add p-benzene Diphenol phosphate intermediate (1) was added to the reaction flask, and reacte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com