Method for decoloration of succinic acid fermentation broth by ion exchange resin

An ion exchange resin, succinic acid technology, applied in the separation/purification of carboxylic acid compounds, organic chemistry and other directions, can solve the problems of non-reusability, affecting unit operation, increasing electrical conductivity, etc., to save separation costs and improve production. The effect of sample flow rate and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

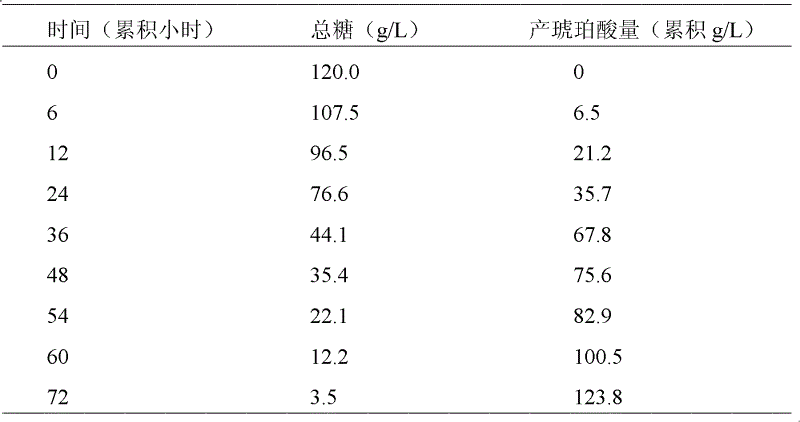

[0030] 1. Fermentation of succinic acid

[0031] The microorganism selected for fermentation is Actinobacillus succinogenes, also known as 130Z T , deposited in the American Type Culture Collection (ATCC), number ATCC55618. The preparation of the medium: the preservation medium and the activation medium are nutrient-rich TSB medium; the seed medium formula (unit: g / L) glucose 10, yeast powder 6, NaCl 1, MgCl 2 2. CaCl 2 1.5, Na 2 HPO 4 2.9, NaH 2 PO 4 2.2; Seed medium formula (unit: g / L) glucose 30, yeast powder 15, urea 2, KCl 4, MgCl 2 2. MnCl 2 0.07, CaCl 2 1.5, Na 2 HPO 4 4.4, NaH 2 PO 4 3.3. Adjust the pH value to 6.4-6.9, and sterilize at 121°C for 30 minutes.

[0032] Under aseptic operation conditions, add seed liquid to the fermentation liquid, the volume percentage of the inoculum is 5-7%, at this time, the amount of succinic acid is 0, start stirring, the rotation speed of the stirring paddle of the bioreactor is 125rpm-150rpm, and feed Filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com