Glass containing protective coating layer

A coating layer and protective technology, applied in the field of removable protective coatings, can solve the problems of increased time and labor costs, touch and damage, etc., and achieve the effects of simplifying the processing process, improving safety, and uniform thickness

Active Publication Date: 2014-12-10

CHANGJIANG GLASS TAIBO

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method of shipping works well for substrates that are not functionally coated or that are of uniform size, however, when shipping functionally coated or non-uniformly sized substrates, a protrusion or corner of a substrate may touch the Touch and damage the surface of the functional coating film adjacent to the substrate or the surface adjacent to the substrate

[0004] In some industries, protective coatings have been used to reduce transportation losses. For example, French patent FR2,295,100 discloses a peelable protective coating for metal, glass and plastic surfaces, composed of 5-40% soluble copolymer It is made of a liquid composition of polyamide, 55-85% ethanol and 0-20% water, but this protective coating film uses a large amount of organic solvents. After the coating is completed, these organic solvents must be recycled or can be effectively disposed of. At the same time, the stripped solid film layer also needs to be effectively treated

Since there may be some residue on the surface when the film is peeled off, time and labor costs are required to inspect and remove the residual film

Also, some organic solvents may be flammable

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment 1

[0028] The manufacturing components, source, and content of each part of the protective coating layer of this embodiment are shown in Table 1, polyvinyl alcohol resin 12.0%, surfactant 0.5%, bactericide 0.115%, deionized water 87.385%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

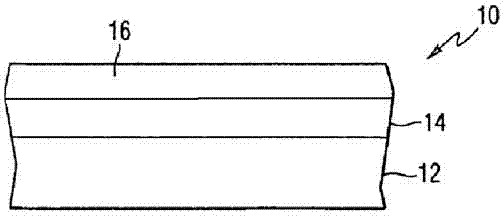

The invention belongs to the field of protective coatings for glass substrates and specifically relates to glass containing a protective coating layer. The glass comprises a substrate layer, wherein the substrate layer is of the glass substrate which only comprises a glass base chip or the glass substrate formed by plating a functional film layer / layers on the glass base chip, the single functional film layer or the multiple functional film layers is / are formed on one surface or two surfaces of the glass base chip, and the glass is characterized by further comprising the protective coating layer which is formed on all or part of the region on the outer surface of the substrate layer; and the protective coating layer is a solvent dissolution type or physical stripping type coating film. According to the glass disclosed by the invention, when the protective coating layer is prepared, an alcohol cosolvent is not used as a water cosolvent and a co-carrier, the using amount of an organic solvent is reduced, and the processing treatment process after the completion of film plating on the glass is simplified; by adding a surfactant, the wettability of a coating composition when the coating composition is applied to the substrate or a functional coating film is increased, and the thickness of the protective coating layer is more uniform; and the protective coating layer has good water solubility and is easy to remove by washing with water and more thorough to remove.

Description

technical field [0001] The invention belongs to the field of protective coatings for glass substrates, in particular to a removable protective coating, which is applicable no matter whether the substrate is coated with a functional coating. Removable protective coatings reduce the susceptibility of substrates and functional coatings to mechanical damage during processing, handling, transport or storage of glass substrates or glass substrates coated with one or more functional coatings. Background technique [0002] In the glass industry, glass manufacturers usually produce large pieces of glass, which are usually larger than 4 inches (1.2m) by 6 inches (1.8m), and then shipped to processors, who will take large pieces of glass Cutting is performed to create various finished products (e.g. architectural windows, clear glass for automobiles, insulating glass (IG) units, mirrors). Typically, such large substrates that need to be further processed or cut into finished products ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C03C17/28

Inventor 林嘉宏

Owner CHANGJIANG GLASS TAIBO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com