Infiltration chamber system for infiltrating, drying and digesting sludge

A technology for digesting sludge and percolation, which is applied in the field of percolation chamber system, can solve the problems of insignificant sludge reduction effect in winter, impact on the surrounding environment of operation, long sludge drying cycle, etc., and achieve improved sludge reduction. Quantify the effect, improve the sludge dewatering performance, and strengthen the effect of digestion and stabilization at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

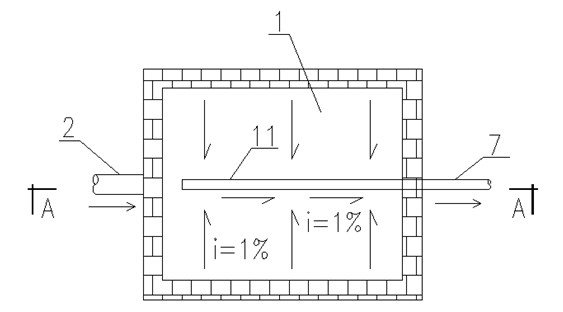

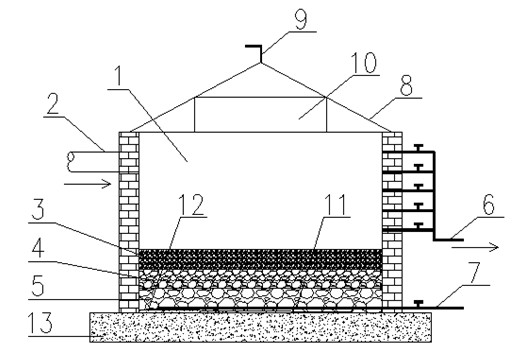

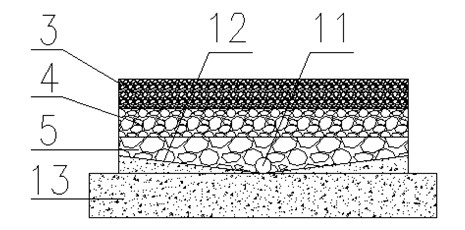

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] see figure 2 , as can be seen from the figure, a percolation chamber system for infiltration drying and digesting sludge includes a percolation chamber 1, a waterproof geomembrane 12 is arranged on the bottom plate 13 of the percolation chamber, and a waterproof geomembrane 12 A filter layer is provided; the feature is that: the thickness of the filter layer is 650~750mm, and the gravel filter material is used to lay the filter layer. The filter material is composed of: the thickness of the upper filter layer 3 is 200-300mm, and the particle size of the filter material is 3-5mm; the thickness of the middle filter layer 4 is 200mm, and the particle size of the filter material is 8-15mm; the thickness of the lower filter layer 5 is 250mm, The particle size is 30-40 mm; a perforated water collection pipe 11 is provided in the lower filter layer 5, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com