Purification process of desulfurization gypsum and gypsum raw materials purified through process

A desulfurization gypsum and process technology, applied in the direction of calcium/strontium/barium sulfate, etc., can solve the problems of high energy consumption and complex process, and achieve the effects of low energy consumption, simple process parameters and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

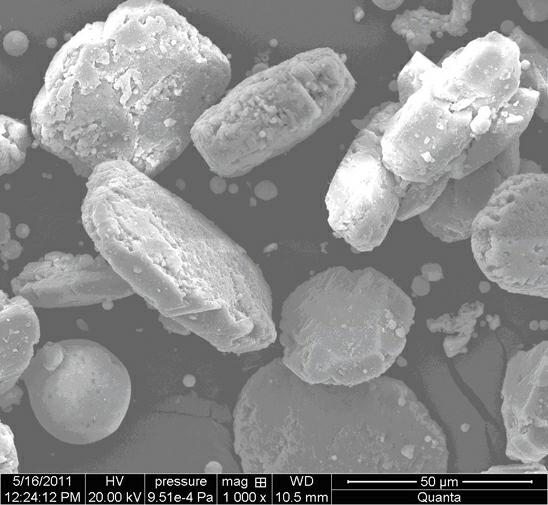

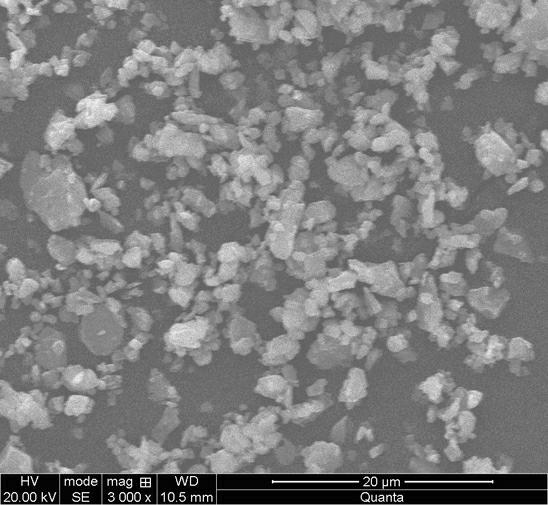

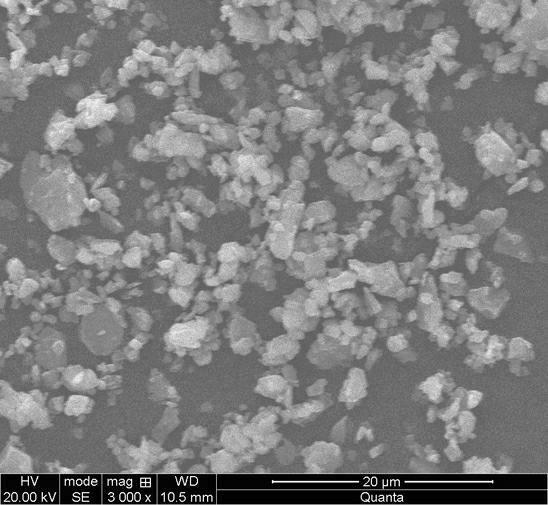

Image

Examples

Embodiment 1

[0041] A purification process of desulfurized gypsum, the purification process comprises the following steps:

[0042] Step 1, take the material: manually select the desulfurized gypsum of the coal-fired power plant as the A sample;

[0043] Step 2. Crushing and screening: The sample A selected in step 1 is sent to the crusher for crushing, and sieved with a 200-mesh and 500-mesh vibrating screen, and the vibrating screen time is 10min;

[0044] Step 3. Primary ball milling: take 200 g of desulfurized gypsum powder with a particle size of 200-500 mesh obtained by crushing and screening in step 2, mix it with 600 g of water to prepare a slurry with a solid-liquid weight ratio of 1:3, and send it to the ball mill , then add 0.4g grinding aid to the slurry, and ball mill for 10min;

[0045] Step 4. Pickling: First, adjust the solid-liquid weight ratio of the slurry obtained in the first ball milling in step 3 to 1:6, then place it in a water bath at 30°C, first add 15ml of sulfu...

Embodiment 2

[0065] A purification process of desulfurized gypsum, the purification process comprises the following steps:

[0066] Step 1, take the material: manually select the desulfurized gypsum of the coal-fired power plant as the A sample;

[0067] Step 2, crushing and screening: the sample A selected in step 1 is sent to the crusher for crushing, and sieved with a 200-mesh and 500-mesh vibrating screen, and the vibrating screen time is 20min;

[0068] Step 3. Primary ball milling: take 200 g of desulfurized gypsum powder with a particle size between 200 and 500 meshes obtained by crushing and sieving in step 2, mix it with 800 g of water to prepare a slurry with a solid-liquid weight ratio of 1:4, and send it to the ball mill , then add 0.1 g grinding aid to the slurry, and ball mill for 15min;

[0069] Step 4. Pickling: First, adjust the solid-to-liquid weight ratio of the slurry obtained in the first ball milling in step 3 to 1:8, then place it in a water bath at 40°C, first add ...

Embodiment 3

[0089] A purification process of desulfurized gypsum, the purification process comprises the following steps:

[0090] Step 1, take material: manually select desulfurized gypsum of coal-fired power plant as B sample;

[0091] Step 2, crushing and screening: the sample B selected in step 1 is sent to the crusher for crushing, and sieved with a 200-mesh and 500-mesh vibrating screen, and the vibrating screen time is 30 minutes;

[0092] Step 3. Primary ball milling: take 200 g of desulfurized gypsum powder with a particle size of 200-500 mesh obtained by crushing and screening in step 2, mix it with 1000 g of water to prepare a slurry with a solid-liquid weight ratio of 1:5, and send it to the ball mill , then add 0.6g grinding aid to the slurry, and ball mill for 20min;

[0093] Step 4. Pickling: firstly adjust the solid-liquid weight ratio of the slurry obtained in the first ball milling in step 3 to 1:10, then place it in a water bath at 20°C, first add 20ml of sulfuric acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com