Purified flue gas recycling device

A technology for recycling and cleaning flue gas, which is applied in the field of cleaning flue gas recycling and processing devices and cleaning flue gas recycling and processing devices, can solve the problems of large water consumption and waste of water resources, and achieve recycling, water saving, The effect of solving the recycling problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

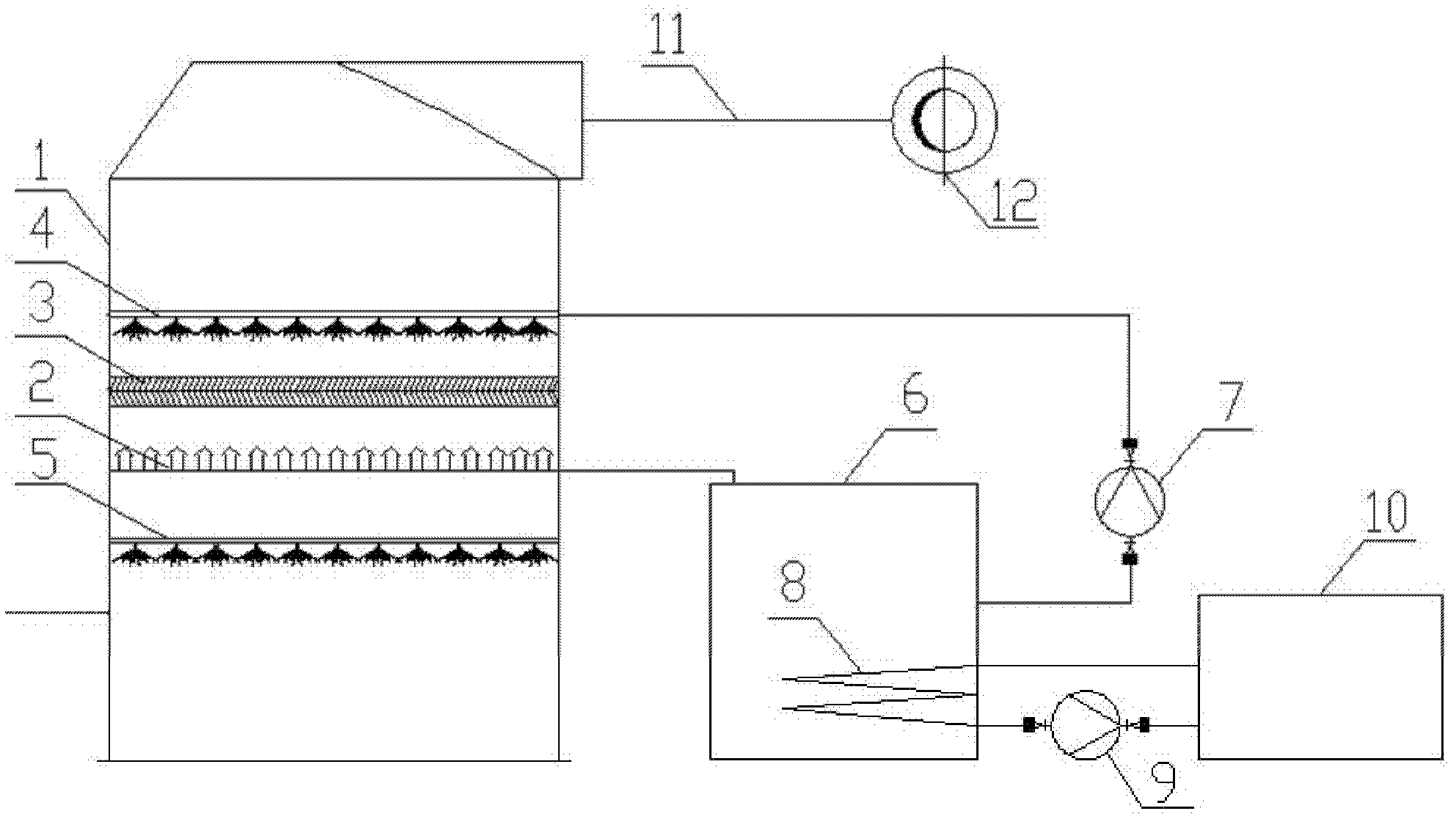

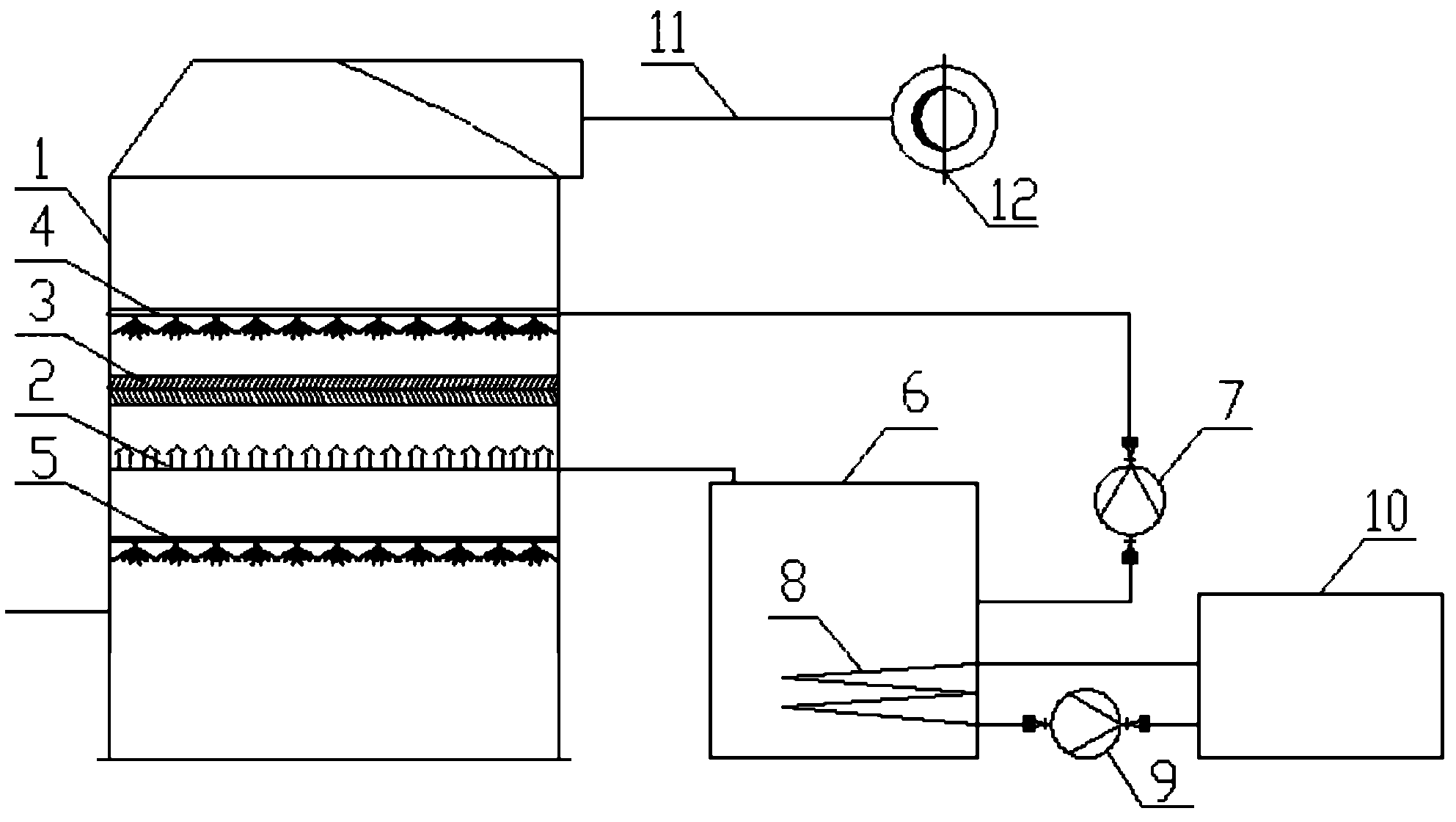

[0016] Such as figure 1 As shown, a clean flue gas recovery treatment device includes: an absorption tower 1, a water-proof air cap water collector 2 arranged from bottom to top in the absorption tower 1, a structured packing layer 3, a cooling spray layer 4 and a demister device (not shown in the figure), and a recycling water circulation device connected to the cooling spray layer 4; the recycling water recycling device includes a recycling water storage device 6, a cooling spray circulating water pump 7, a heat exchanger 8, and a heat exchange circulating pump 9. Closed circulation cooler 10, one side of the recovered water storage device 6 is connected to the cooling spray layer 4 through the cooling spray circulating water pump 7, and the other side of the recovered water storage device 6 is connected to the water-proof air cap water collector 2 The heat exchanger 8 is arranged in the recycled water storage device 6 , and the closed cycle cooler 10 is connected to the rec...

Embodiment 2

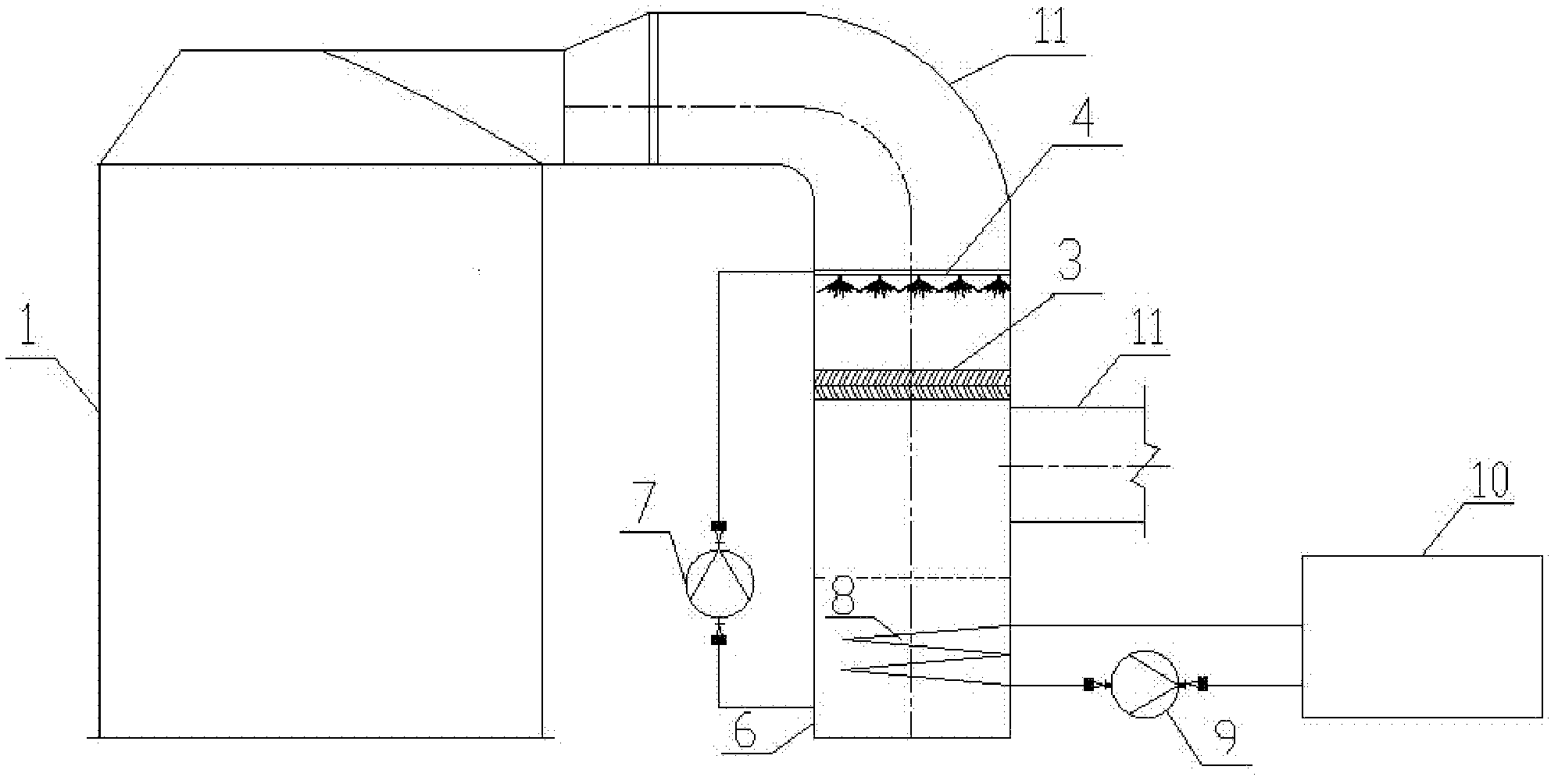

[0019] Such as figure 2 As shown, a clean flue gas recovery treatment device includes: a clean flue 11, a structured packing layer 3 arranged from bottom to top in the clean flue 11, a cooling spray layer 4 and a demister (not shown in the figure) , and a recycling water circulation device connected to the cooling spray layer 4; the recycling water recycling device includes a recycling water storage device 6, a cooling spray circulating water pump 7, a heat exchanger 8, a heat exchange circulating pump 9, and a closed circulation cooler 10. The recovered water storage device 6 is connected to the cooling spray layer 4 through the cooling spray circulating water pump 7, the heat exchanger 8 is set in the recovered water storage device 6, and the closed circulation cooler 10 is connected to the recovery water through the heat exchange circulating pump 9. A water storage device 6 is connected.

[0020] When applying the clean flue gas recovery treatment device of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com