Vegetable fiber hollow capsule used for medicine and its preparation method

A technology of hollow capsules and plant fibers, which is applied in capsule delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc. It can solve the problem of bleeding, affecting the quality and production qualification rate of medicinal hollow capsules, and the gel strength is too hard And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

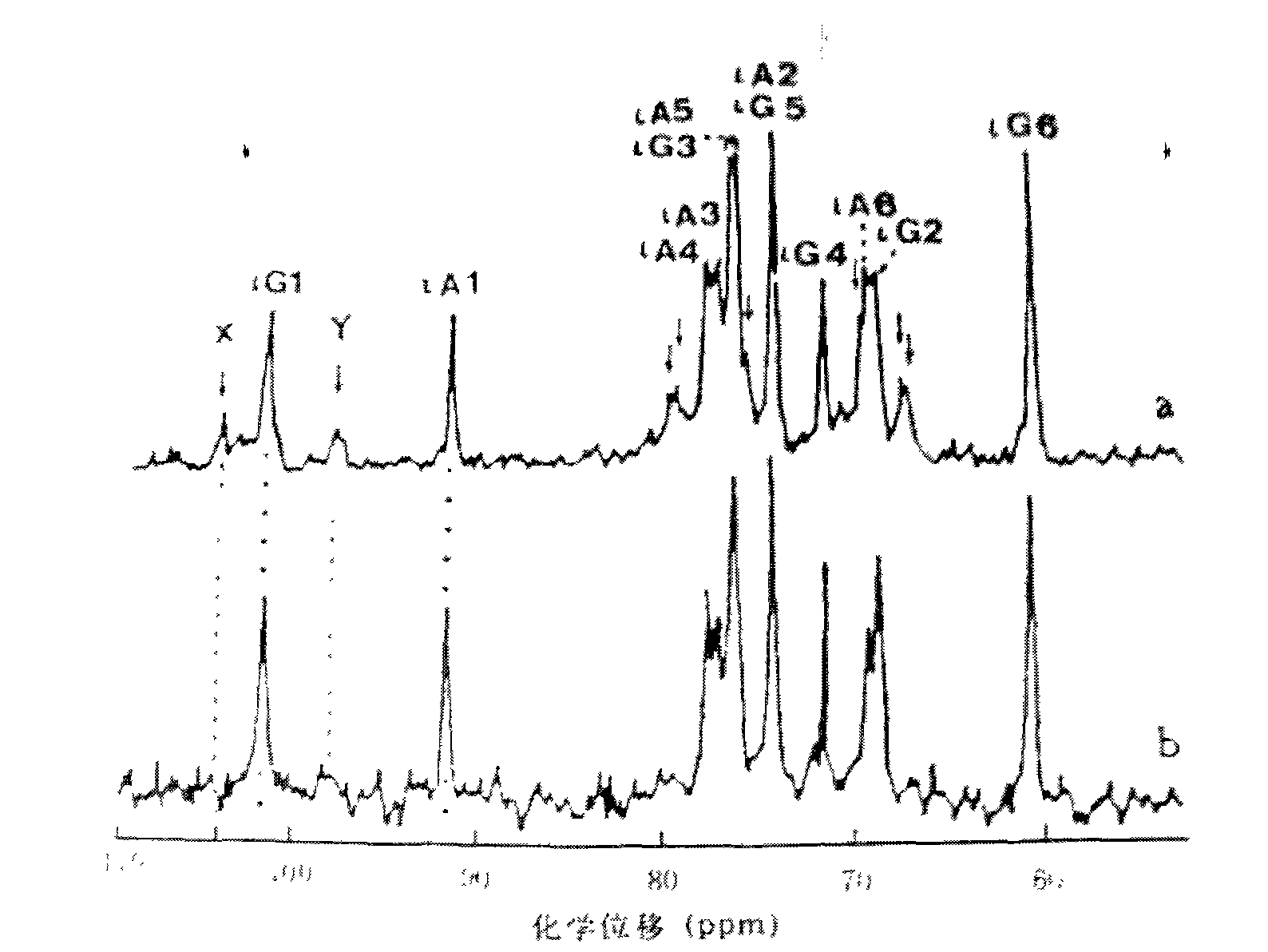

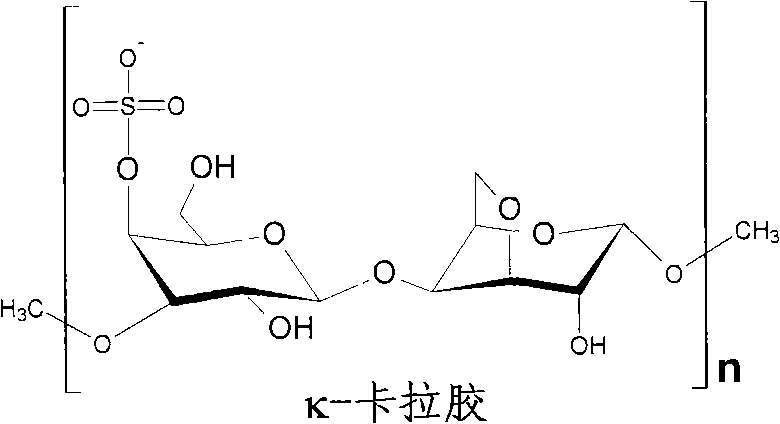

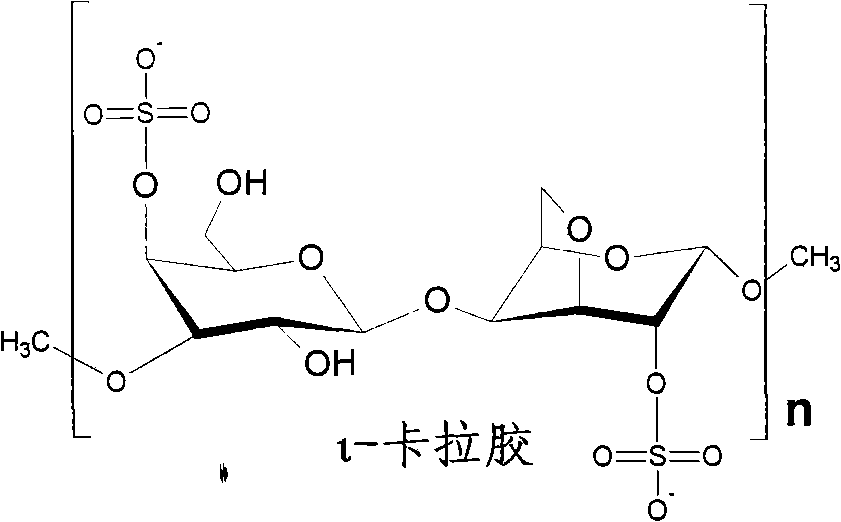

Method used

Image

Examples

Embodiment 1

[0049] 1) Eucheuma spinosa extract glue containing 50% water:

[0050]Add 20 kg of dried Eucheuma spinosa, rinse with 40 kg of fresh water and drain, add 150 kg of 7% KOH solution, stir and react for 1-1.5 hours, filter out impurities with a 300-mesh sieve and drain. Soak and stir with 0.5M / L hydrochloric acid solution to adjust the pH to 7-8. Add 400 kg of hot water, keep the temperature at 100°C, and pass through a 300-mesh sieve while hot after 60 minutes. After cooling to room temperature, freeze at -15°C for 24 hours, thaw and dehydrate with water at 15°C to obtain a 50% water-containing Eucheuma spinosa extract glue. Alkaline solution

[0051] 2) By weight, when the water is 100 parts (1 kg is 1 part), add 3.0 kg of Eucheuma spinosa extract glue containing 50% water, heat to 85°C while stirring and keep it for 30 minutes, then gradually cool down When the temperature reaches 50°C, add 10 kg of cellulose hydroxypropyl methyl ether (HPMC) and stir evenly for 10 minutes,...

Embodiment 2

[0053] The preparation method of the Eucheuma spinosa extract glue containing 50% water is the same as that in Example 1.

[0054] According to the weight ratio, water is 100 parts, 1.5 kg of Eucheuma spinosa extract glue containing 50% water, 20 kg of 90°C hot water is added while stirring, and the temperature is gradually lowered to 50°C after keeping for 30 minutes. Add 50 kg of distilled water at room temperature to 13 kg of cellulose hydroxypropyl methyl ether (HPMC) while stirring, and stir for 20 minutes until the solution becomes a transparent homogeneous liquid. Add 15 kg of room temperature distilled water to 2 kg of hydroxyethyl methylcellulose (HEMC) while stirring, and keep stirring for 30 minutes until the solution presents a transparent viscous liquid, then combine and stir the above solutions (85 kg) and keep the temperature at 50 ℃. Add 1 kg of modified starch to 15 kg of finishing water, stir well, combine all the solutions, and continue stirring for 10 minu...

Embodiment 3

[0056] The preparation method of the Eucheuma spinosa extract glue containing 50% water is the same as that in Example 1.

[0057] In terms of weight ratio, when the water is 100 parts, add 5.5 kilograms of Eucheuma spinosa extracting glue containing 50% moisture, add 80 kilograms of 90 ℃ hot water while stirring and stir for 30 minutes, then gradually cool down to 60 ℃, add 5 After one kilogram of hydroxyethylmethylcellulose (HEMC) was stirred evenly for 10 minutes, the temperature was naturally lowered to 50° C., and the stirring was continued until the solution appeared transparent. Add 5kg of modified starch into 20kg of hot water at 90°C and stir to dissolve, then combine with the above solution, continue to stir until uniform viscous liquid, keep the temperature at 50°C for 2 hours. Add it into the storage tank of the hollow capsule semi-automatic equipment, keep at 48-50°C for 20 minutes, turn on the machine, let the glue in the storage tank flow into the material tank,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com