Reinforcement for thermoplastic GFRP (Glass Fiber Reinforced Polymer) butterfly cable and production process of reinforcement

A butterfly optical cable and production process technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of low production speed and high use cost, and achieve the effect of high production speed, low use cost and high cost performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

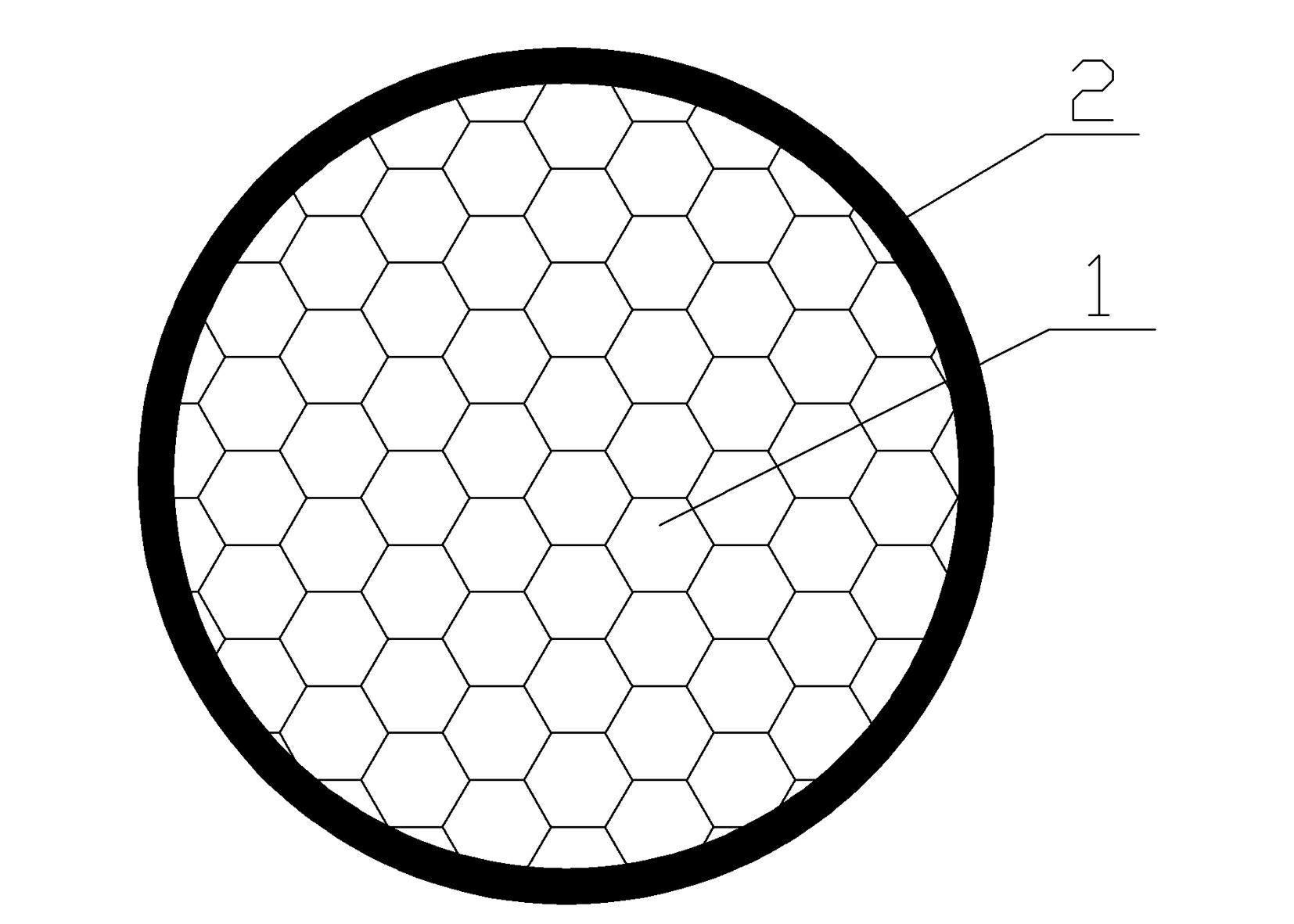

[0019] Such as Figure 1-2 As shown, the reinforcing member for thermoplastic GFRP butterfly cable of the present invention includes a body 1 , the body 1 is a round rod bonded by glass fiber and resin glue, and the surface of the body 1 is coated with a plastic coating layer 2 .

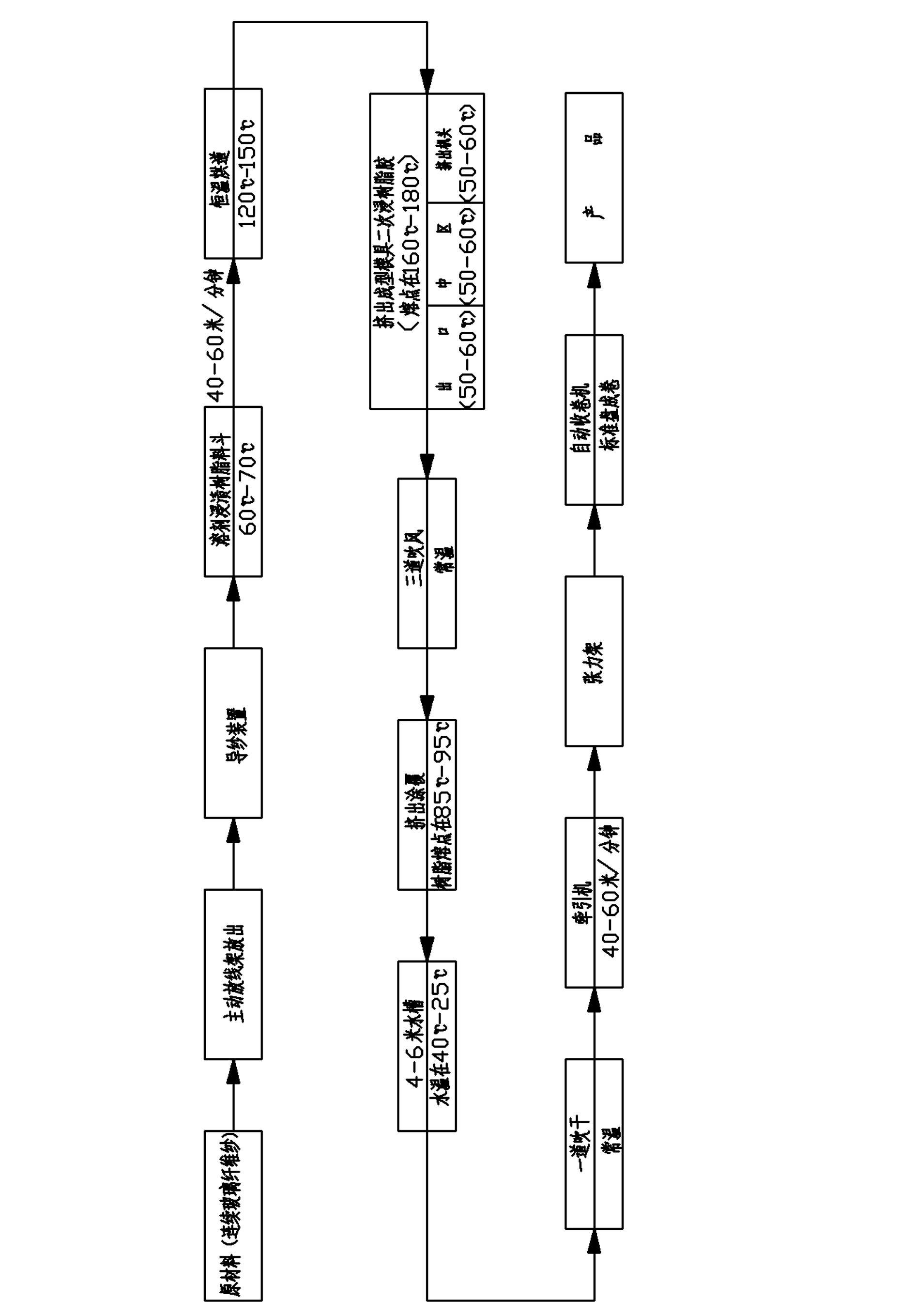

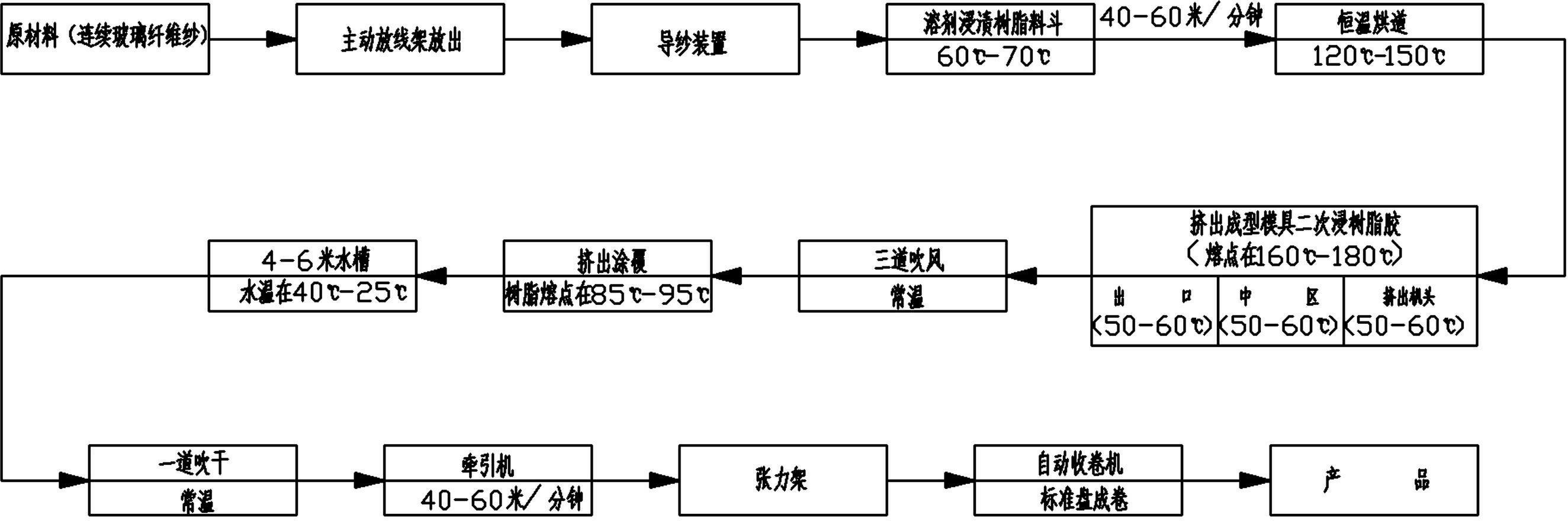

[0020] The production process of reinforcing parts for thermoplastic GFRP butterfly optical cable. Multiple glass fibers are released from their own active pay-off racks, and pass through the yarn guide frame that can guide the glass fibers into the center of the molding mold. The glass fibers are surface treated through a solvent-impregnated resin hopper. The hopper The inner temperature is 60°C, the glass fiber in the hopper passes through the immersion of the alcohol-soluble nylon resin solution in the hopper at a constant speed of 40 m / min, is dried in a drying tunnel at a temperature of 120°C, and then enters the extrusion mold through the guide holes of the extrusion molding mold. Out of the m...

Embodiment 2

[0023] The production process of reinforcing parts for thermoplastic GFRP butterfly optical cable. Multiple glass fibers are released from their own active pay-off racks, and pass through the yarn guide frame that can guide the glass fibers into the center of the molding mold. The glass fibers are surface treated through a solvent-impregnated resin hopper. The hopper The inner temperature is 65°C, the glass fibers in the hopper pass through the immersion of the alcohol-soluble nylon resin solution in the hopper at a constant speed of 50 m / min, and are dried in a drying tunnel with a temperature of 130°C, and then enter the extrusion mold through the guide holes of the extrusion molding mold. Out of the mold for secondary impregnation of resin glue, the volume content of the resin glue is controlled by the mold to 18%, cooled and formed in a mold at a temperature of 55°C, and then air-cooled to room temperature by three blowers, and then coated by extrusion One layer of plastic ...

Embodiment 3

[0026] The production process of reinforcing parts for thermoplastic GFRP butterfly optical cable. Multiple glass fibers are released from their own active pay-off racks, and pass through the yarn guide frame that can guide the glass fibers into the center of the molding mold. The glass fibers are surface treated through a solvent-impregnated resin hopper. The hopper The inner temperature is 70°C, the glass fibers in the hopper pass through the immersion of the alcohol-soluble nylon resin solution in the hopper at a constant speed of 60 m / min, and are dried in a drying tunnel with a temperature of 150°C, and then enter the extrusion mold through the guide holes of the extrusion molding mold. Out of the mold for secondary impregnation of resin glue, the volume content of the resin glue is controlled by the mold to 20%, cooled and formed in a mold with a temperature of 60°C, and then air-cooled to room temperature by three blowers, and then coated by extrusion One layer of plasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com