Surface-modified sensing element and surface modifying method thereof

A technology for surface modification and sensing elements, which can be used in measuring devices, biological testing, and phase-influenced characteristic measurement. It can solve the problems of uneven hydrophilicity on the surface of metal coatings, increased experimental instability, and lengthy process time. Achieve the effects of enhancing detection effect and accuracy, improving sensitivity and sensitivity, and controlling the density of bonded molecules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] See Figures 1A to 1D , is a schematic flowchart of the method for surface modification of the sensing element of the present invention.

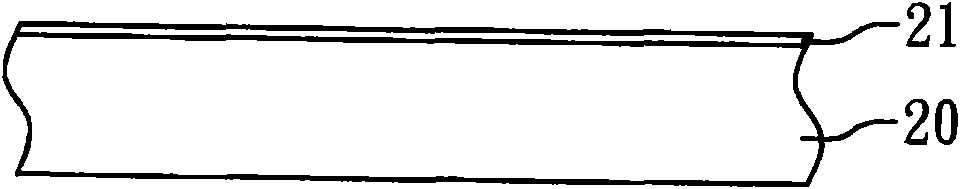

[0030] First, if Figure 1A As shown, a sensing element 20 is provided, wherein a metal film 21 is provided on the surface of the sensing element 20 . In this embodiment, the sensing element 20 is an optical fiber sensing element, such as a side-throwing optical fiber sensing element, which has a sensing area on its surface, and deposits a thin metal film on the surface of the sensing area by sputtering or the like. A gold film is provided as the metal thin film 21 .

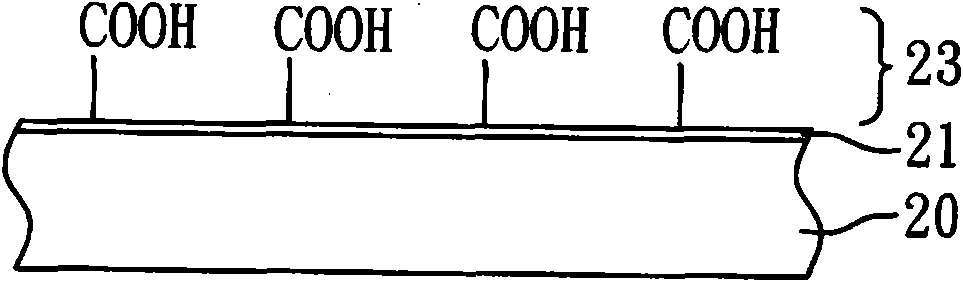

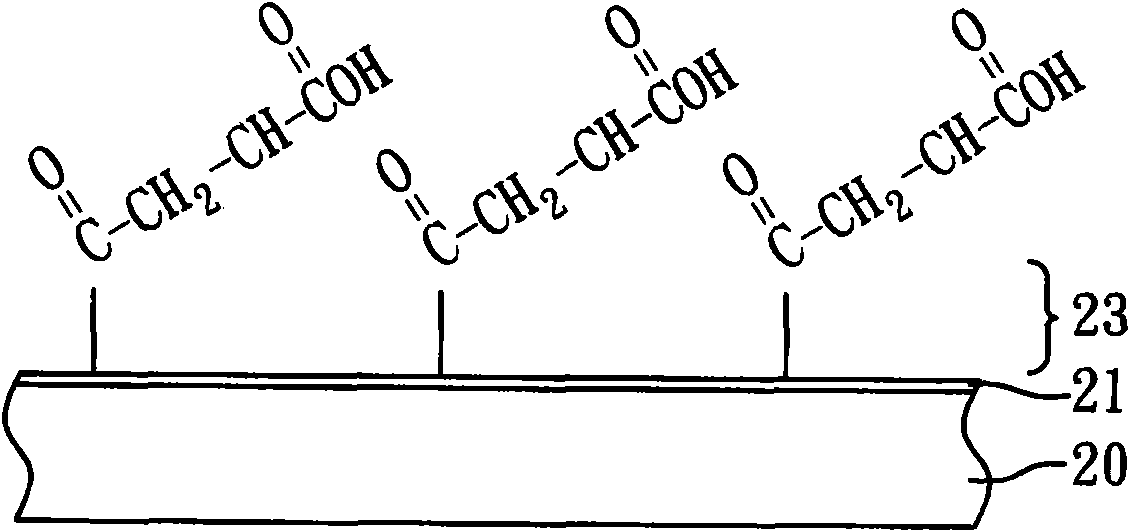

[0031] Next, if Figure 1B As shown, a surface modification layer 23 having a plurality of carboxyl groups is formed on the metal thin film 21 of the sensing element 20 by using isopropanol plasma. In this embodiment, the isopropanol plasma is carried out in the following manner: use isopropanol as the raw material gas, pass it into the vacuum discharge tube, and af...

Embodiment 2

[0034] first. As described in the first embodiment, the surface of the sensing element 20 is modified so that the surface modification layer 23 and the polyacrylic acid layer 24 are formed on the surface of the metal thin film 21 of the sensing element 20 .

[0035] Next, if Figure 1E As shown, the use of a coupling activator promotes the activation of the carboxyl group of the polyacrylic acid layer 24, and provides a plurality of biomolecules 25, prompting the amine groups of the biomolecules 25 to bond with the carboxyl groups of the polyacrylic acid layer 24 to form a biological molecular layer. In this example, the coupling activator used is 1-ethyl-3-(3-dimethylaminopropyl)carbodiimide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com