Cellulose-potassium titanate composite membrane as well as preparation method and application thereof

A technology of potassium titanate and cellulose, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of high preparation cost, poor material toughness and strength, etc., and achieve good mechanical properties, simple and easy operation, good light transmission and bioavailability degradability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A method for preparing a cellulose-potassium titanate composite membrane provided in an embodiment of the present invention comprises the following steps:

[0022] S1. Pre-cooling the alkaline solution and potassium titanate to obtain a mixed solution, and mixing the mixed solution with cellulose to obtain a cellulose-potassium titanate mixed solution.

[0023] It should be noted that cellulose cannot be melted and dissolved in general solvents at room temperature due to the strong hydrogen bond interaction between cellulose molecules; in alkaline solutions, small molecules of urea and sodium hydroxide solvent can be combined with Cellulose forms hydrogen bonds, which are more stable at low temperatures, and then destroy the hydrogen bonds between cellulose molecules to realize the dissolution of cellulose in alkaline solution. Therefore, the present invention adopts low temperature and mixes potassium titanate and cellulose in alkaline solution, which significantly inc...

Embodiment 1

[0045] The present embodiment provides a kind of preparation method of cellulose-potassium titanate composite film, it comprises the following steps:

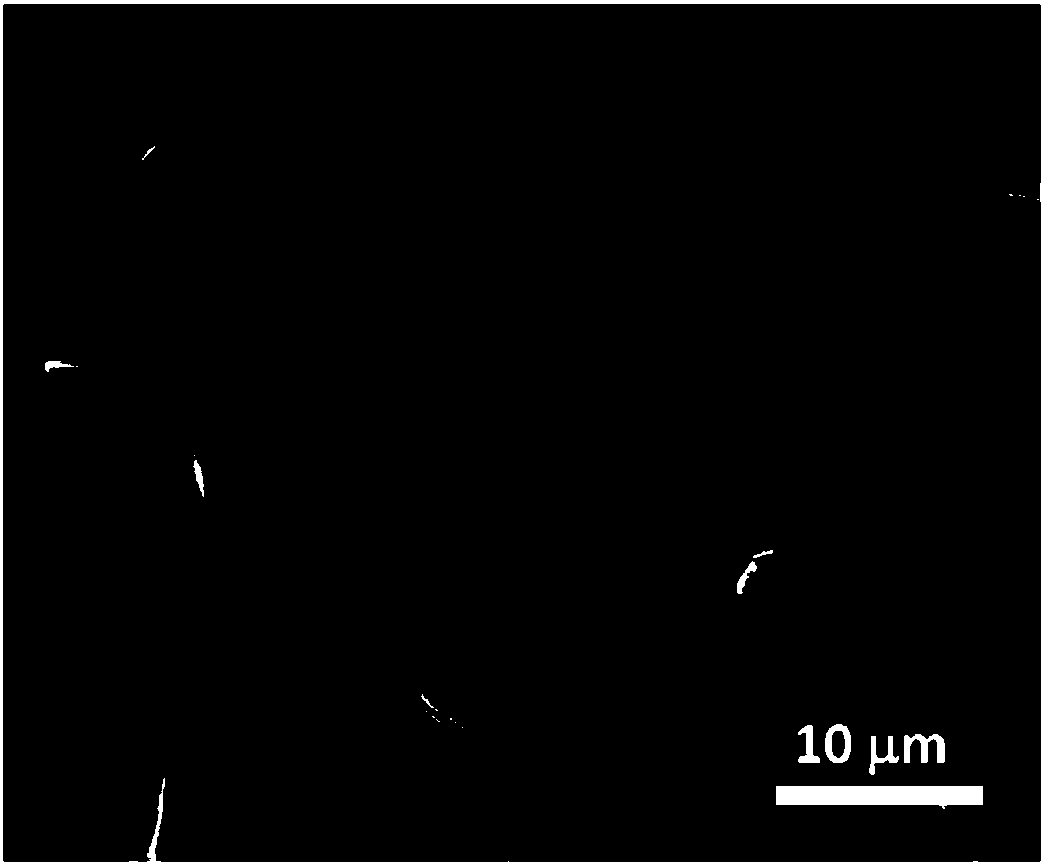

[0046] First, 8.0g LiOH·H 2 O and 15.0 g of urea were dissolved in 71.9 g of water to obtain 94.9 g of LiOH-urea solution, and 0.1 g of potassium titanate with a length of 7 μm and a diameter of 0.7 μm was added to the LiOH-urea solution, mechanically stirred for 1 h, then ultrasonically treated for 10 min, and placed Pre-cool in the refrigerator to -12.0°C, add 5.0 g of cellulose powder, and mechanically stir for 10 minutes to obtain a cellulose-potassium titanate mixed solution.

[0047] Next, centrifuge the cellulose-potassium titanate mixed solution at -5°C at a speed of 3000r / min for 15 minutes to defoam, pour the solution on a glass plate and control the thickness of the liquid layer to 0.2mm, The layered glass plate was gently soaked in ethanol solution for 6 hours to prepare the cellulose-potassium titanate composite h...

Embodiment 2

[0051] The present embodiment provides a kind of preparation method of cellulose-potassium titanate composite film, it comprises the following steps:

[0052] First, 8.0g LiOH·H 2 O and 15.0 g of urea were dissolved in 71.9 g of water to obtain 94.9 g of LiOH-urea solution, and 0.1 g of potassium titanate with a length of 7 μm and a diameter of 0.7 μm was added to the LiOH-urea solution, mechanically stirred for 1 h, then ultrasonically treated for 10 min, and placed Pre-cool in the refrigerator to -12.0°C, add 5.0 g of cellulose powder, and mechanically stir for 10 minutes to obtain a cellulose-potassium titanate mixed solution.

[0053] Next, centrifuge the cellulose-potassium titanate mixed solution at -5°C at a speed of 3000r / min for 15 minutes to defoam, pour the solution on a glass plate and control the thickness of the liquid layer to 0.2mm, The layered glass plate was gently soaked in ethanol solution for 6 hours to prepare the cellulose-potassium titanate composite h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com