Device and method for testing forming limit of sheet material in three-dimensional stress state

A sheet metal forming, three-dimensional stress technology, applied in the direction of testing the ductility of the material, can solve the problem that the Nakazima test method cannot meet the blank deformation, etc., and achieve the effect of simple method and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

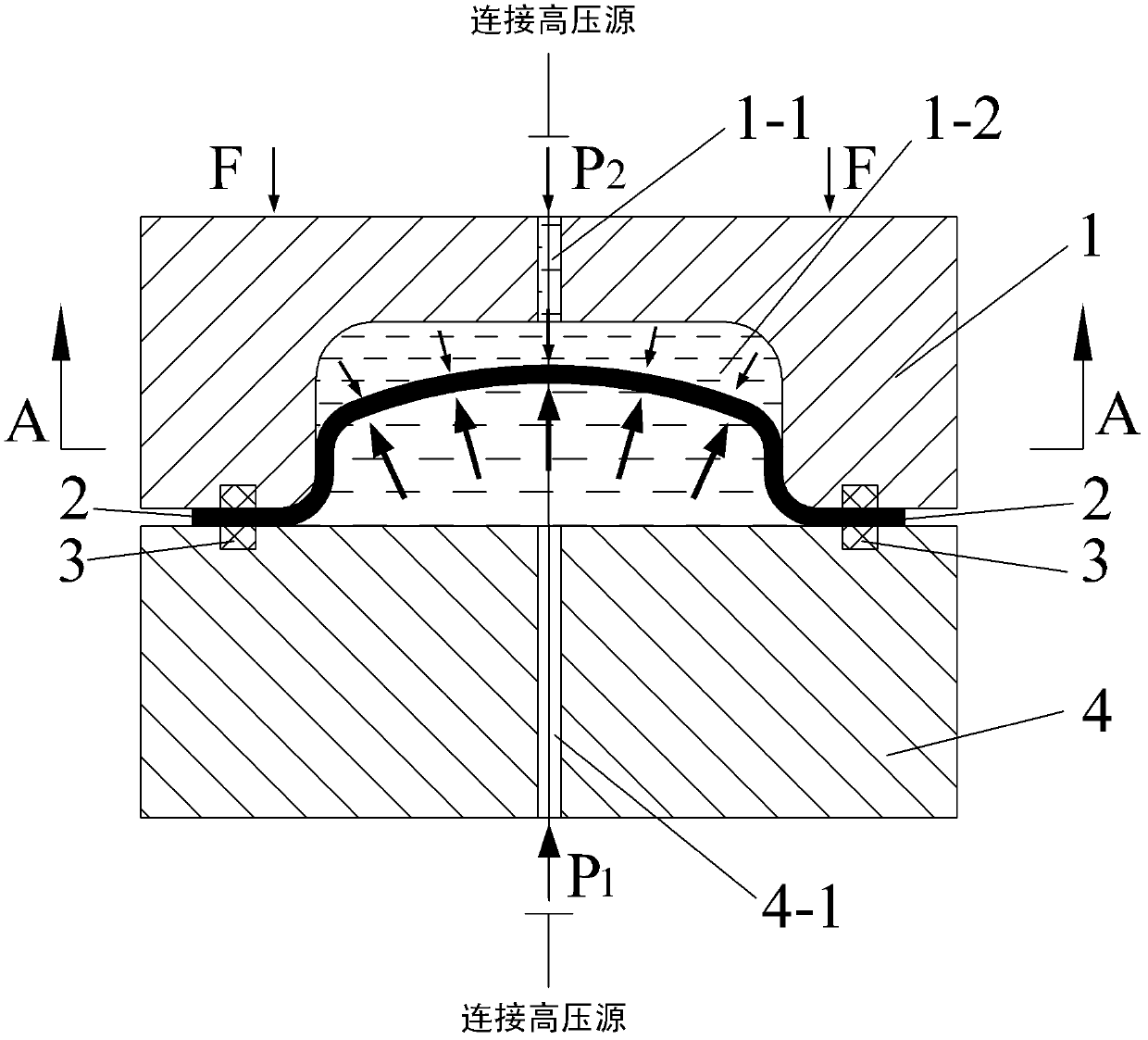

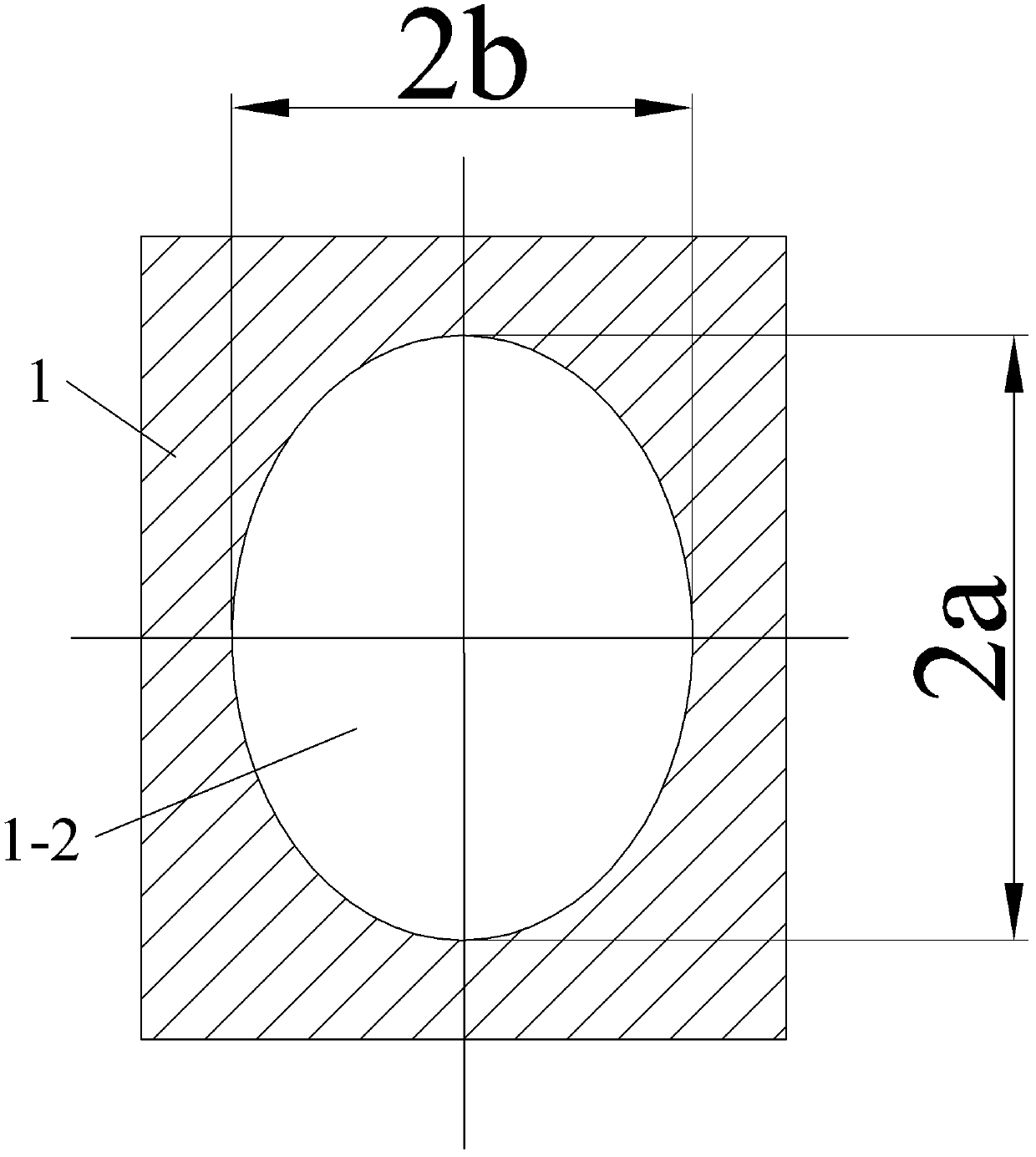

[0021] Specific implementation mode one: as Figure 1-5 As shown, the plate forming limit test device under the three-dimensional stress state described in this embodiment includes an upper mold 1 and a lower mold 4, the inner surface of the cavity 1-2 of the upper mold 1 is an elliptical cylinder, and the upper mold The upper mold liquid injection hole 1-1 communicated with the mold cavity 1-2 is provided on the top of 1; 1, the axis of the liquid injection hole 4-1 of the lower mold, and the centerline of the cavity 1-2 along the length direction are arranged coaxially, and the upper mold 1 and the lower mold 4 are sealed by the sealing ring 3 after mold closing. After the upper mold 1 and the lower mold 4 are closed, the liquid injection hole 4-1 of the lower mold communicates with the opening of the cavity 1-2, and the upper mold 1 is connected with the slider of the press; the lower mold 4 is connected with the press The workbench is connected and fixed; both the upper m...

specific Embodiment approach 2

[0022] Specific implementation mode two: as Figure 1-5 As shown, the test method for sheet metal forming limit under the three-dimensional stress state using the test device described in the first embodiment described in this embodiment is realized according to the following steps:

[0023] Step 1. Prepare multiple sets of test devices according to claim 1. The ratios of the major and minor axes of the elliptical sections of the cavity 1-2 in each test device are different, and the ratios of the major and minor axes of each elliptical cross section are uniformly selected within the range of 1 to 2.5. ;

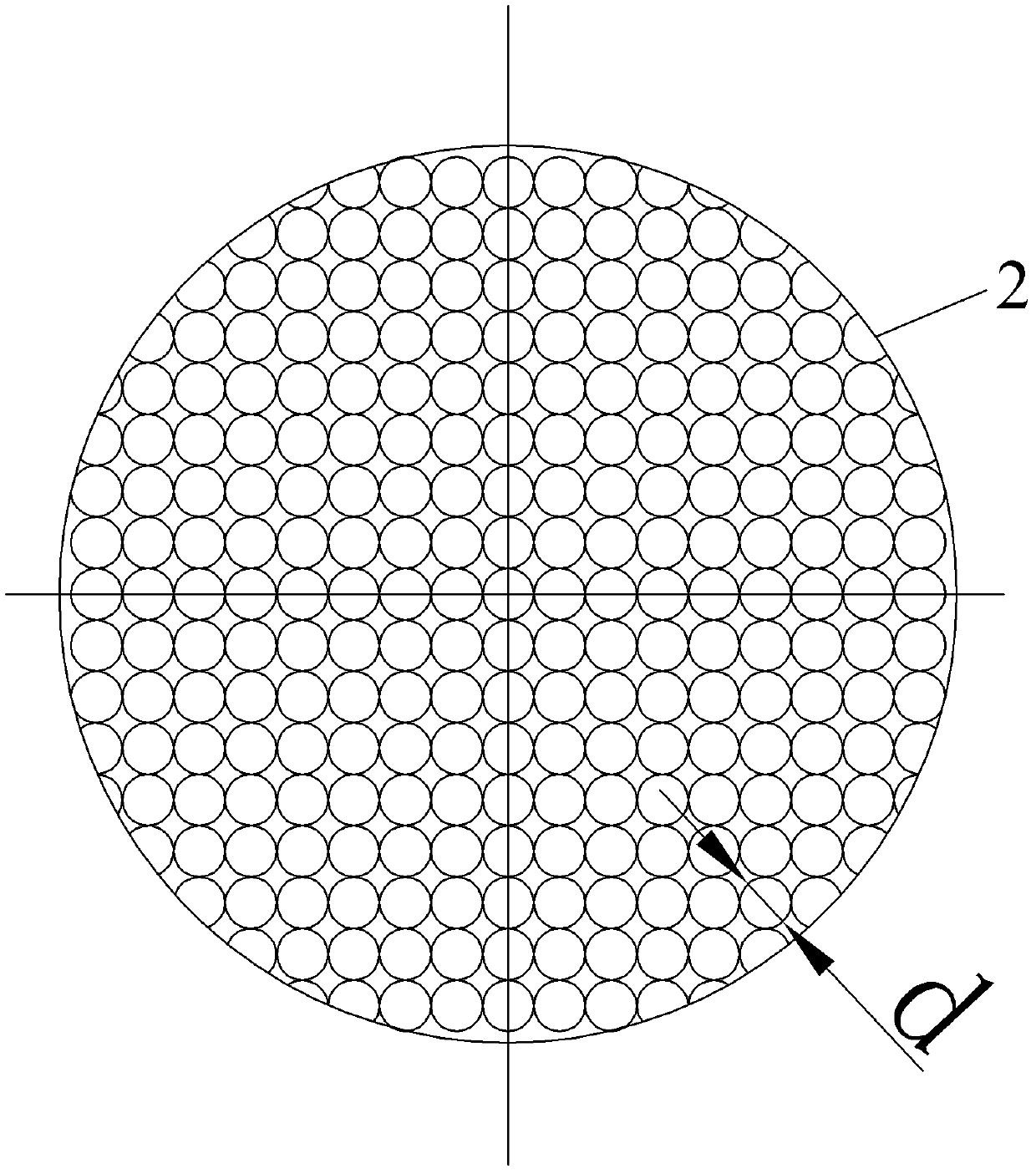

[0024] Step 2, making the metal sheet sample: using electro-corrosion method to make a plurality of circular or square dents arranged in a matrix on the upper surface of the circular metal sheet sample, so that the upper surface of the circular metal sheet sample is Circular grid or square grid arranged in matrix; measure the diameter d of circular or square dents or the sid...

specific Embodiment approach 3

[0034] Specific embodiment three: In this embodiment, seven sets of test devices according to claim 1 are prepared in step one, and the ratios of major and minor axes of the elliptical cross-sections of cavity 1-2 in each test device are respectively 1, 1.2, 1.4, 1.6, 1.8 , 2.0 and 2.5, the minor axis length is 50mm, and the major axis is 50mm, 60mm, 70mm, 80mm, 90mm, 100mm and 125mm respectively; in step 2, the diameter of the circular metal plate sample produced is 200mm. Other steps are the same as in the second embodiment.

[0035] The pressure P in the fluid medium chamber 1-2 (cavity 1-2) 2 It plays the role of applying normal pressure and establishing a three-dimensional stress state. The pressure P in the fluid medium cavity (lower mold liquid injection hole 4-1) 1 Make the sample bulge. This method can not only replace the Nakazima test method to determine the bulging limit, but also evaluate the influence of the normal stress on the forming limit in the three-dimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com