Leftovers cleaning and recovering process in cottonseed velvet peeling production line

A technology for scraps and production lines, applied in recycling technology, fiber processing, separation of plant fibers from seeds, etc., can solve problems such as waste of available resources, environmental pollution, and low processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Based on the characteristics of the leftovers, the inventor believes that it is necessary to explain the source of the leftovers, especially how to obtain them and the properties of the obtained leftovers.

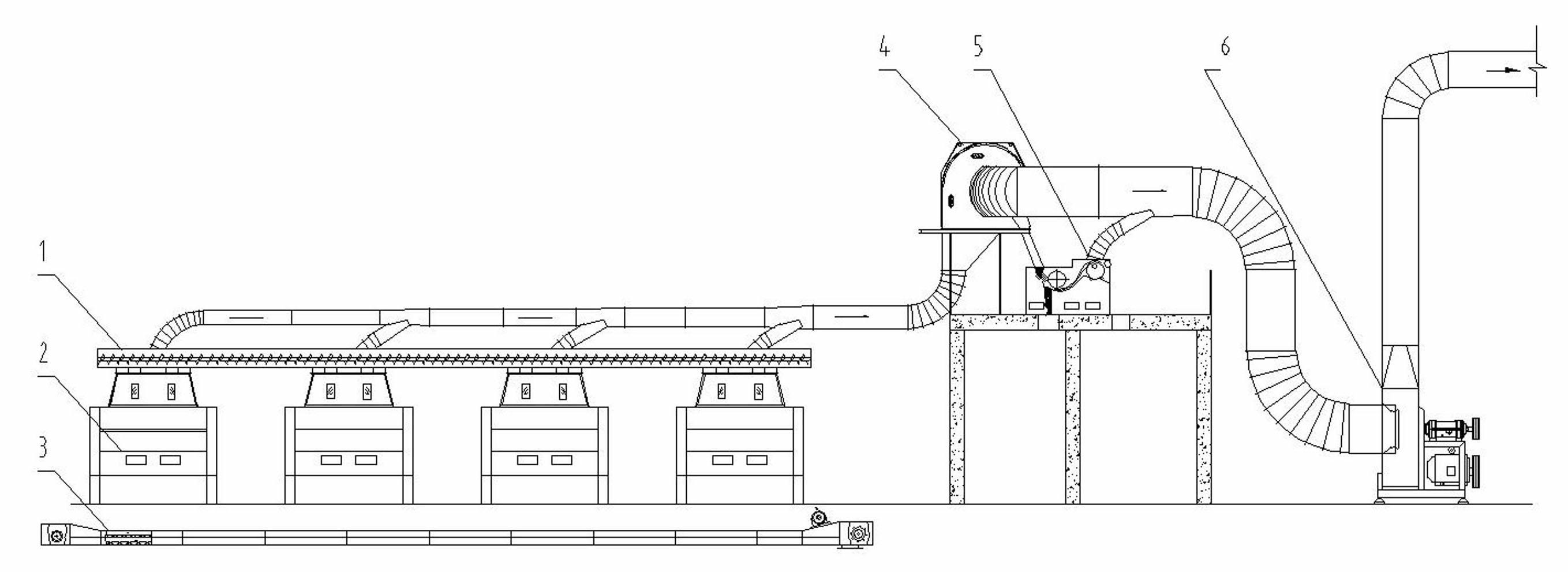

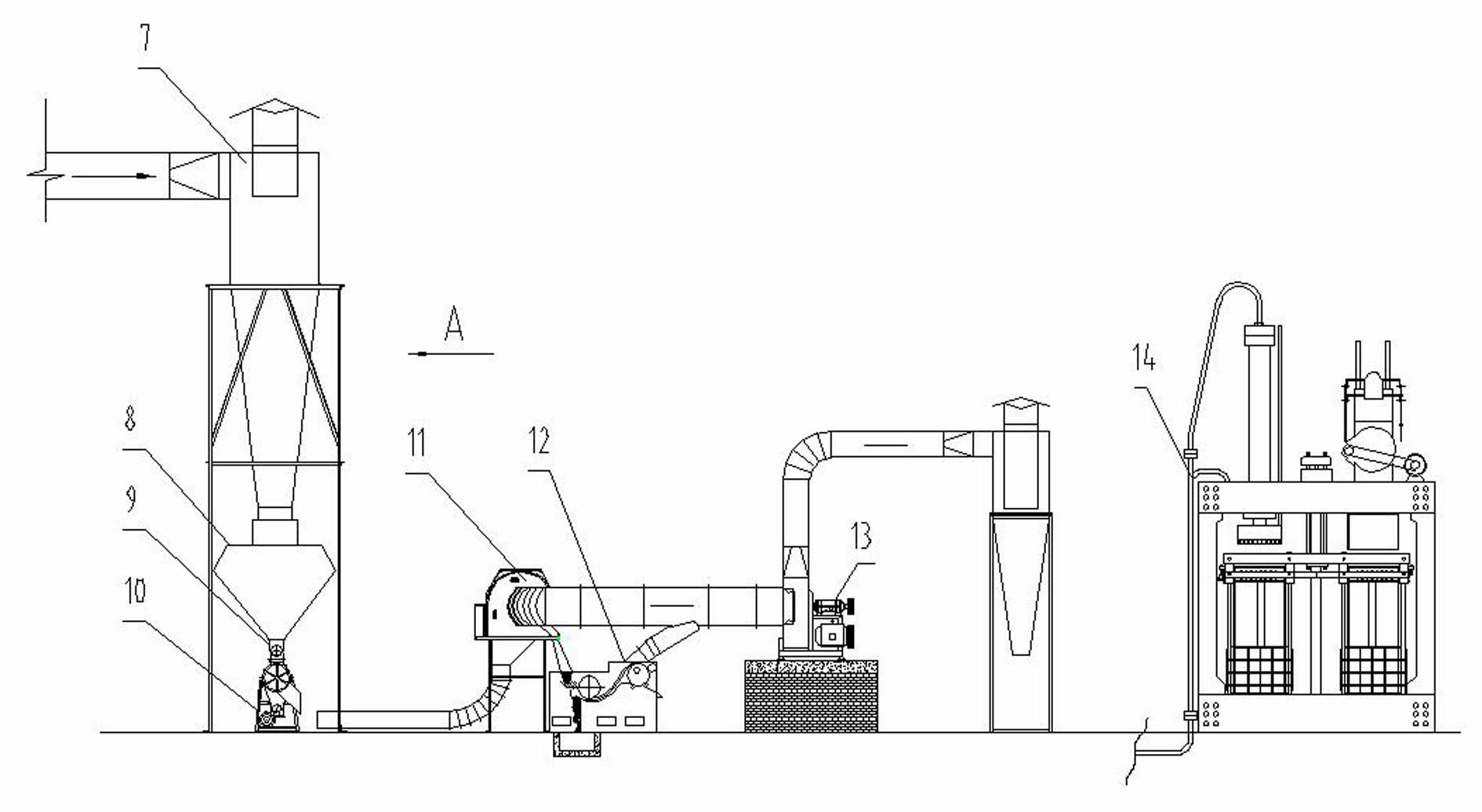

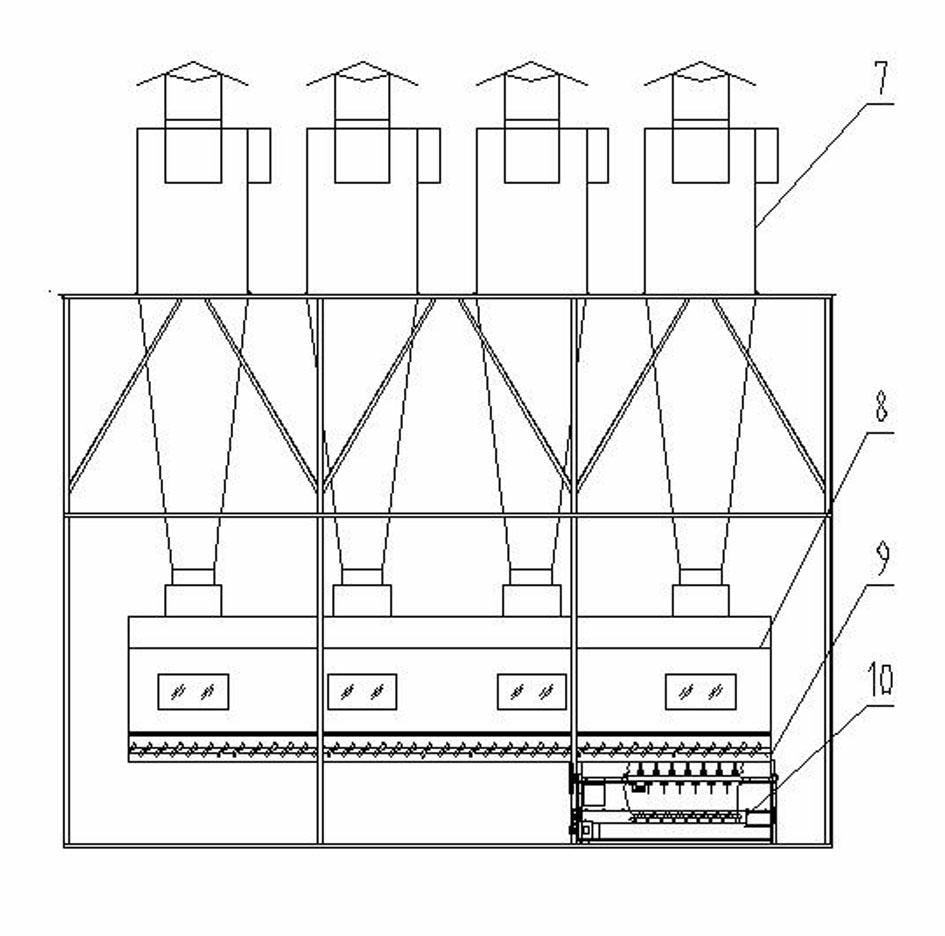

[0023] Refer to the attached figure 1 , is a schematic diagram of the structure of a commonly used cottonseed velvet production line. The arrow above indicates the direction in which the velvet fan 6 conveys materials to the cyclone dust collector 7. The cottonseed velvet production line determines the properties and characteristics of the materials entering the cyclone dust collector. device of.

[0024] Correspondingly, the relevant production process of the corresponding cottonseed peeling production line includes the following steps:

[0025] a) On the stripping production line: the cottonseed distribution auger 1 distributes the cottonseed to the corresponding stripping machine 2 for stripping, separates the cottonseed and the short-staple mixture with the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com