Low density, high strength and high plasticity titanium alloy

A high-strength, high-plasticity technology, applied in the field of titanium alloys, can solve the problems of hardening and increase the brittleness of alloy materials, and achieve the effects of refining grains, inhibiting crystal nucleation, and reducing processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Table 1 The specific composition ratio of T91 alloy

[0013] serial number Pure aluminum / % Vanadium aluminum alloy / % Al-Si Alloy / % Sponge titanium / % Example 1 7.14 1.99 0.49 90.38 Example 2 6.84 1.99 0.49 90.68 Example 3 7.30 1.53 0.49 90.68 Example 4 7.60 1.53 0.49 90.38 Example 5 6.74 2.29 0.49 90.48 Example 6 7.44 1.99 0.49 90.08

[0014] Note: The above proportions are percentages by weight

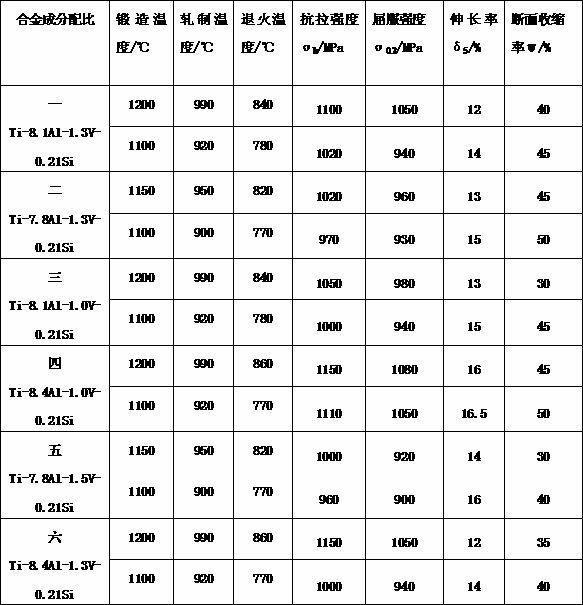

[0015] The same alloy adopts two different processing technology systems, and adjusts the composition ratio of the alloy under the same technology system. Finally, through the comparison of mechanical properties, it is found that Ti-8.4Al-1.0V-0.21Si is forged at 1200°C and rolled at 990°C. It has high strength after annealing at 860°C and maintains high plasticity.

[0016] Table 2 T91 processing technology and mechanical properties

[0017]

[0018] The golf head manufacturing industry conducts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com