Inorganic phase change energy storage material

An energy storage material and inorganic phase change technology, applied in the field of energy storage materials, can solve the problems of energy storage system energy storage density reduction, etc., and achieve the effects of large thermal conductivity, good crystallinity, and large volume heat storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

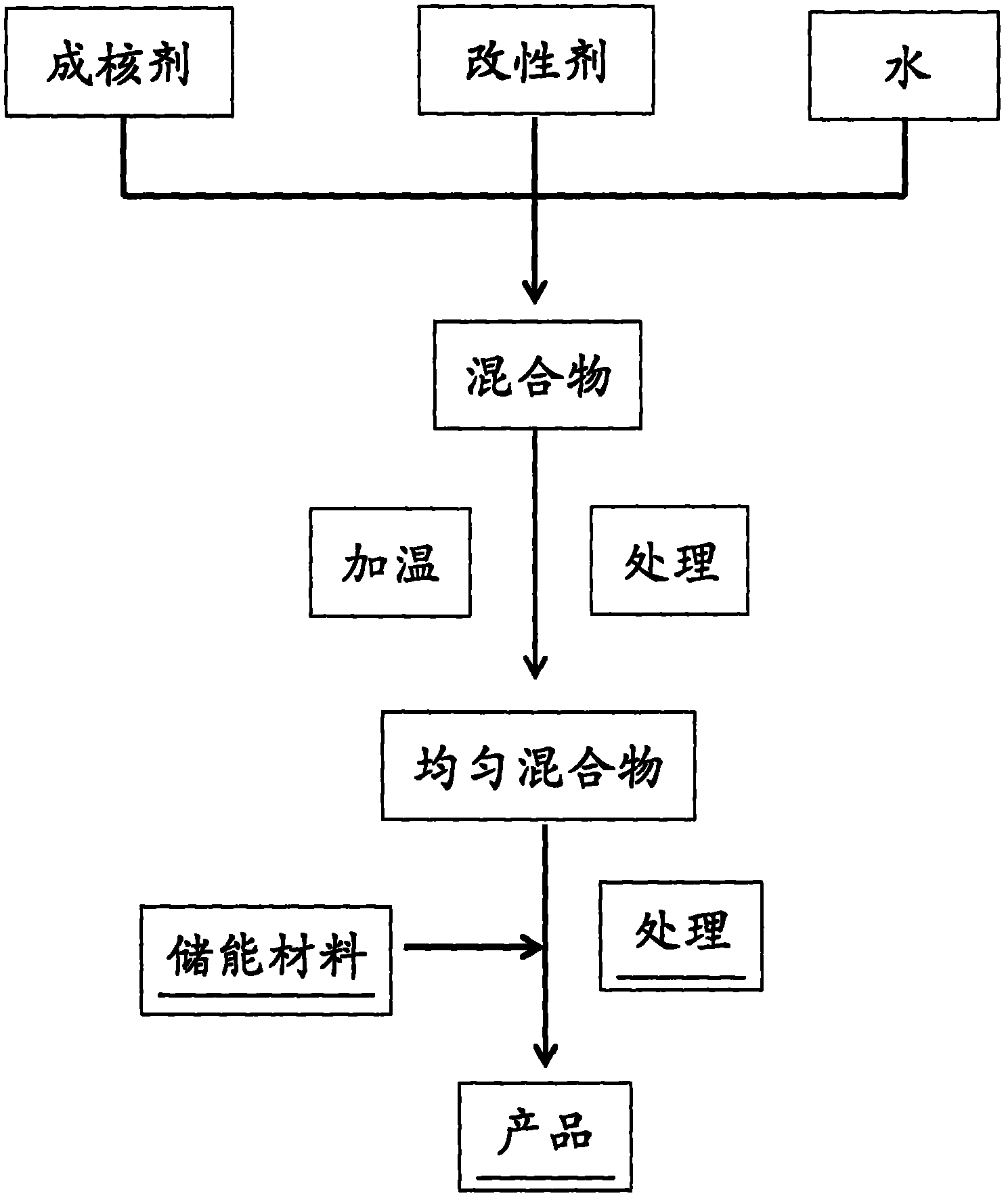

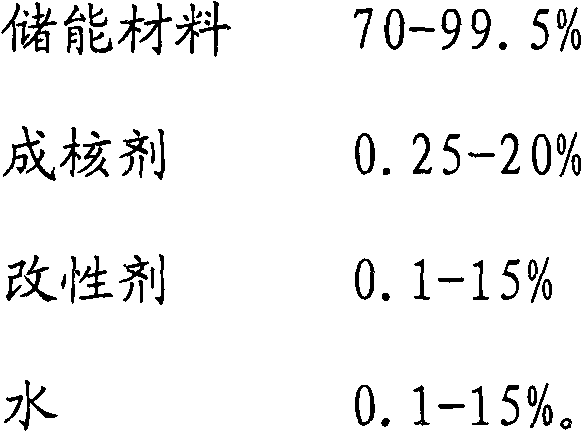

Method used

Image

Examples

Embodiment 1

[0023] The barium carbonate (nucleating agent) of 0.25Kg, the sodium polyaspartate (modifier) of 0.1Kg and 0.15Kg water are fully mixed, and then heated to more than 60° C. to obtain a uniformly mixed mixture; Add 99.5Kg of barium hydroxide octahydrate to the mixture, heat the mixture to about 80°C to fully melt the barium hydroxide octahydrate, stir vigorously after melting until the mixture of the four materials is uniform, until the mixture does not have stratification, that is, the obtained Product A1.

[0024] The above obtained product A1 was subjected to DSC analysis, and the results are shown in Table 1. In addition, the step cooling curve test was carried out on the product A1, and the results are shown in Table 2.

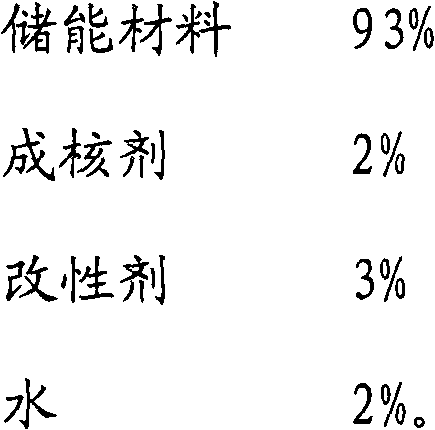

Embodiment 2

[0026] Mix 2.0Kg of calcium carbonate (nucleating agent), 1.0Kg of hydrolyzed maleic anhydride (modifier) and 4.5Kg of water thoroughly, then heat to above 60°C to obtain a uniformly mixed mixture; Add 93Kg of sodium acetate trihydrate, heat the mixture to about 80°C to fully melt the sodium acetate trihydrate, stir vigorously after melting until the mixture of the four materials is uniform, until the mixture does not have stratification, and the product A2 is obtained.

[0027] The above obtained product A2 was subjected to DSC analysis, and the results are shown in Table 1. In addition, the step cooling curve test was carried out on the product A2, and the results are shown in Table 2.

Embodiment 3

[0029] 1.5Kg of strontium carbonate (nucleating agent), 2.0Kg of sodium hydroxymethyl cellulose (modifier) and 3.0Kg of water, fully mixed, then heated to more than 60 ° C to obtain a uniform mixture; Add 87Kg of sodium sulfate dodecahydrate to the mixture, heat the mixture to about 80°C to fully melt the sodium sulfate dodecahydrate, stir vigorously after melting until the mixture of the four materials is uniform, until the mixture has no stratification, and the product is obtained A3.

[0030] The above obtained product A3 was analyzed by DSC, and the results are shown in Table 1. In addition, the step cooling curve test was carried out on the product A3, and the results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com