Preparation method of polyurethane nanometer composites

A technology of nanocomposite materials and polyurethane, which is applied in the field of natural polymer nanocomposite materials, can solve problems such as hindering the interaction between cellulose nanocrystals and the matrix interface, limiting the application of cellulose nanocrystals, etc., and achieving the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of polyurethane nanocomposite material, it comprises the steps:

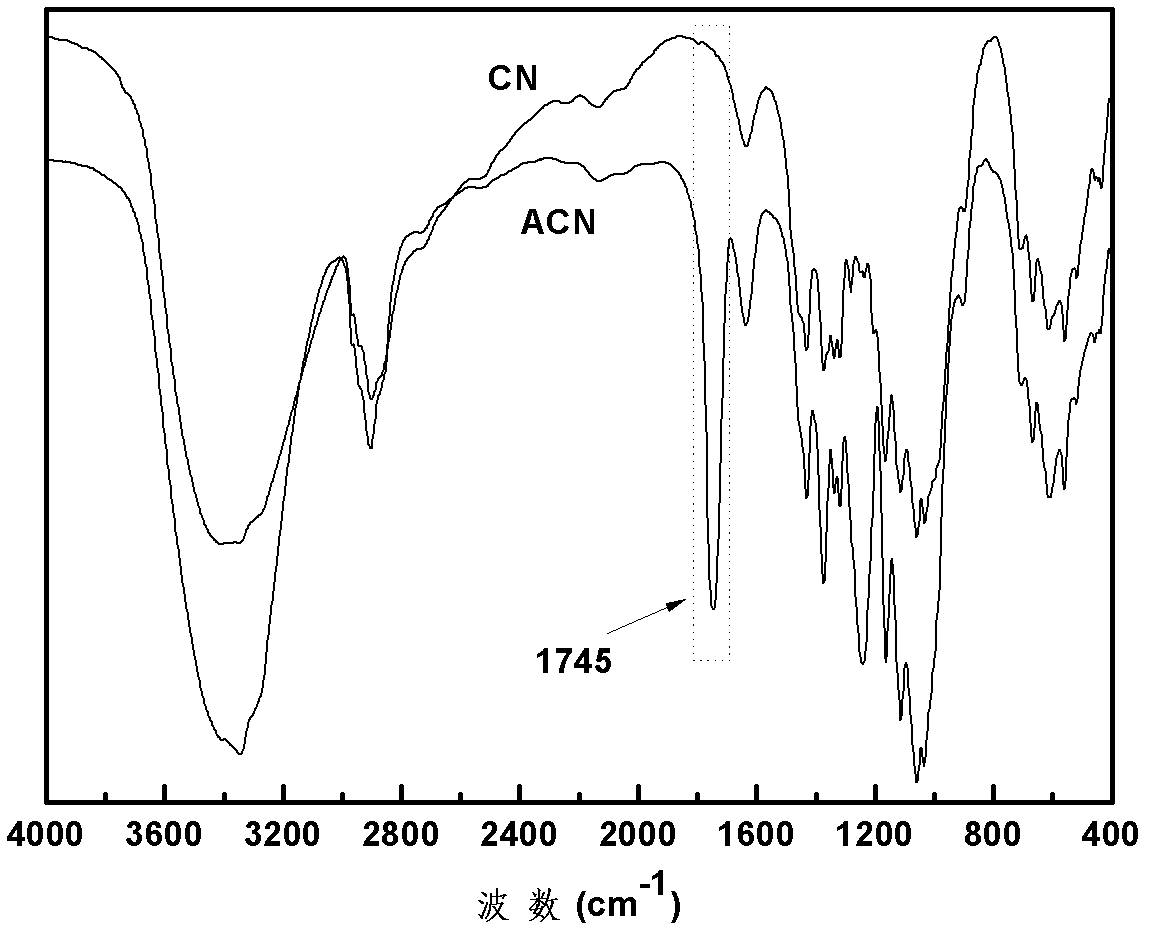

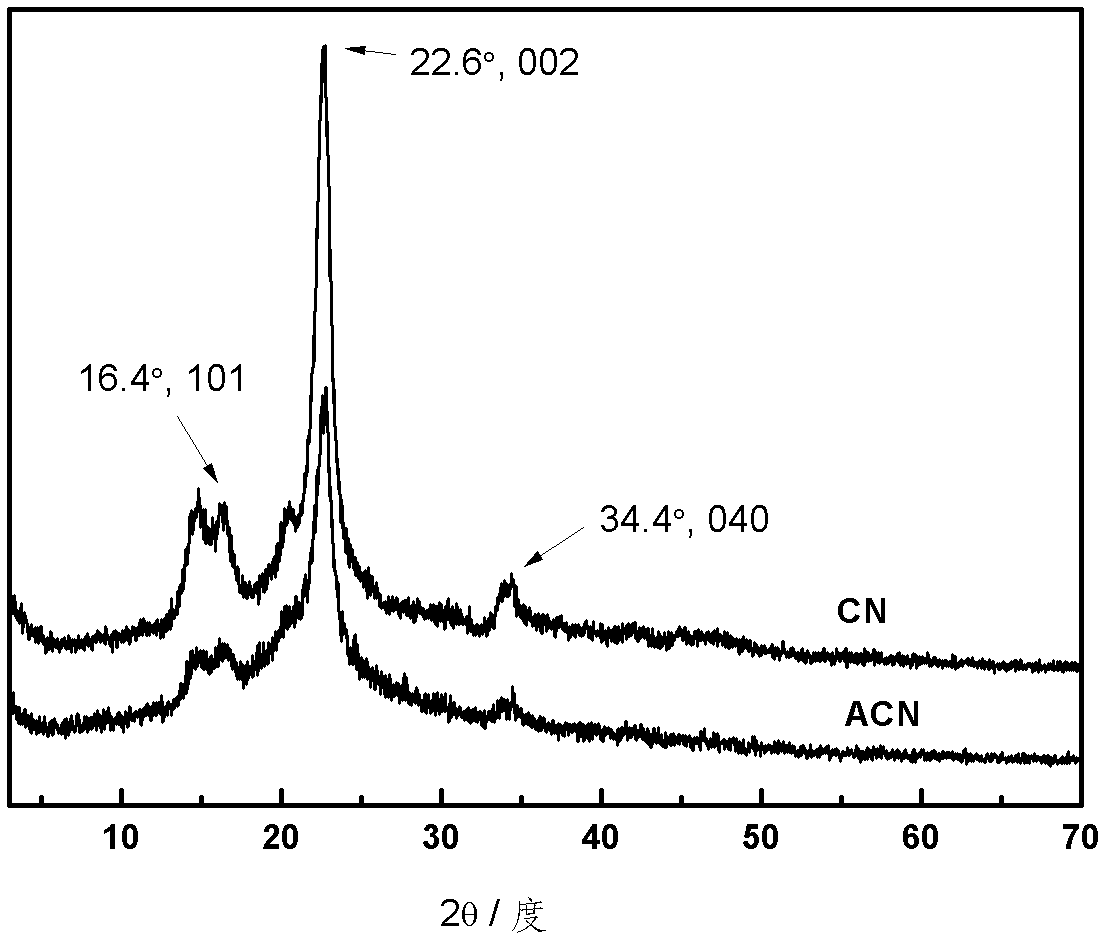

[0025] 1) Surface modification of nanoparticles [Using cellulose nanocrystals (CN) as the nanofiller of polyurethane, introducing -C(=O)CH which has good surface compatibility with oily polyurethane through one-step modification 3 Functional group]: According to the ratio of cellulose nanocrystals, acetic anhydride, and anhydrous pyridine: 1g: 5ml: 30ml, select cellulose nanocrystals, acetic anhydride, and anhydrous pyridine for later use; vacuum-dry cellulose nanocrystals for 30 minutes before reacting (vacuum degree is 0.1~0.5MPa, temperature is room temperature);

[0026] Dissolve cellulose nanocrystals (CN) in anhydrous pyridine first, then ultrasonically disperse for 15 minutes, and react with acetic anhydride under heating and nitrogen protection conditions (high-purity nitrogen is passed through the reaction, purity ≥ 99.9wt%), and the heating reaction temperature at 80°C, the...

Embodiment 2

[0034] A preparation method of polyurethane nanocomposite material, it comprises the steps:

[0035] 1), basically the same as step 1) in Example 1, the difference is:

[0036] According to the ratio of cellulose nanocrystals, acetic anhydride and anhydrous pyridine as 1g: 8ml: 30ml, select cellulose nanocrystals, acetic anhydride and anhydrous pyridine for future use; the rest of the steps are the same as step 1) in Example 1.

[0037] 2), and step 2) in embodiment 1) is basically the same, the difference is:

[0038] The added amount of the solvent tetrahydrofuran is 65% of the total mass of the modified nanoparticles, castor oil-based polyurethane prepolymer, chain extender and tetrahydrofuran; the rest of the steps are the same as step 2) in Example 1.

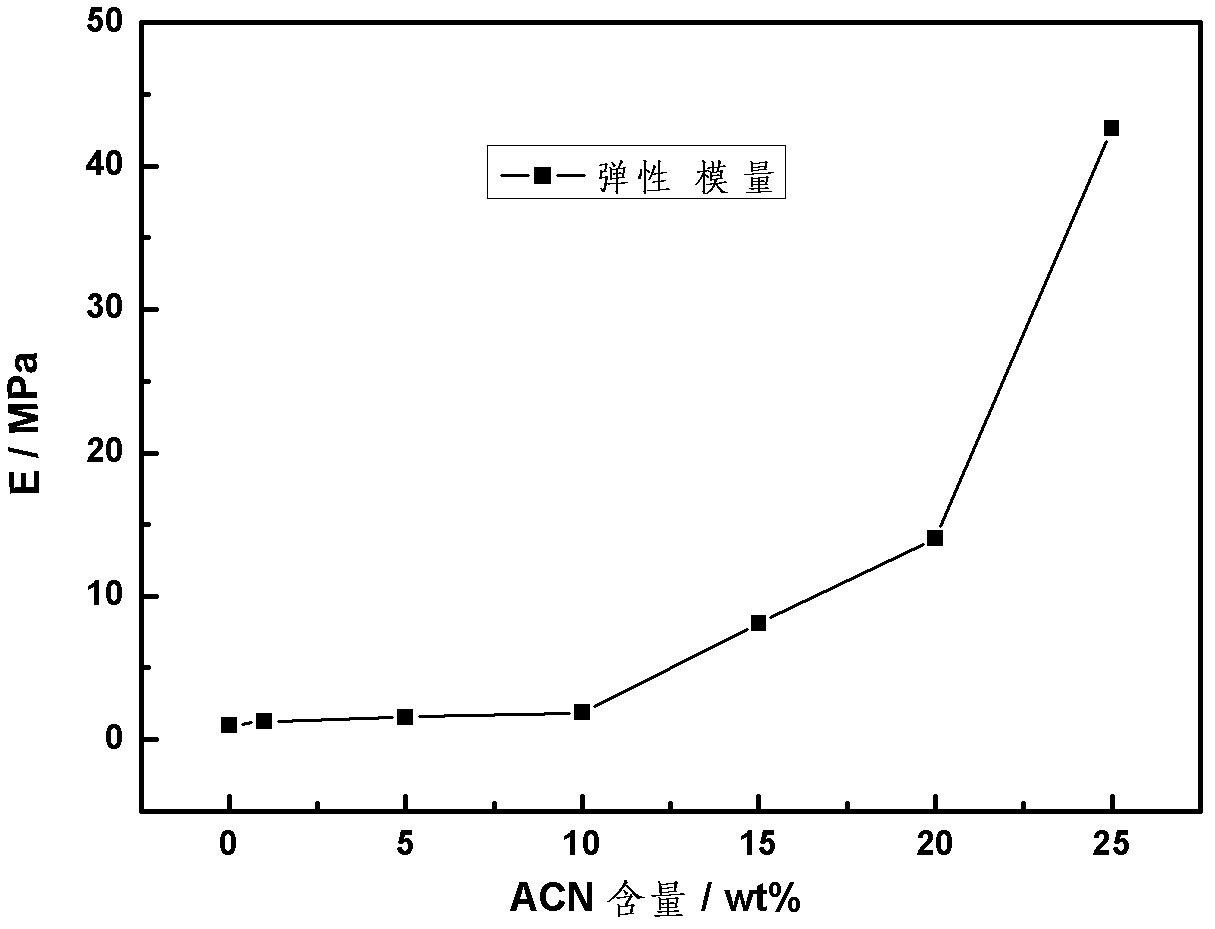

[0039] The mechanical property data of this embodiment gained polyurethane nanocomposite material is: modulus of elasticity (E) 1.60MPa, tensile strength (σ b )6.21MPa, elongation at break (ε b ) 293.13%. The measureme...

Embodiment 3

[0041] A preparation method of polyurethane nanocomposite material, it comprises the steps:

[0042] 1), basically the same as step 1) in Example 1, the difference is:

[0043] According to the ratio of cellulose nanocrystals, acetic anhydride, and anhydrous pyridine as 1g: 5ml: 35ml, select cellulose nanocrystals, acetic anhydride, and anhydrous pyridine for subsequent use; the rest of the steps are the same as step 1) in Example 1.

[0044] 2), and step 2) in embodiment 1) is basically the same, the difference is:

[0045] According to the mass ratio of castor oil and toluene diisocyanate as 3: 1, the castor oil after drying is reacted with toluene diisocyanate (TDI) to form carbamate groups to obtain castor oil-based polyurethane prepolymer, and the remaining steps are the same Step 2) in Example 1.

[0046] The mechanical property data of this embodiment gained polyurethane nanocomposite material is: modulus of elasticity (E) 1.59MPa, tensile strength (σ b )6.665MPa, el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com