A cementitious gel plugging agent and preparation method thereof

A cementitious and gel technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of secondary leakage, loose plugging layer, poor temperature resistance, etc., to improve temperature resistance and firmness. blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 42 parts of sulfonated melamine, 15.75 parts of acrylamide, 2.25 parts of dimethyl diallyl ammonium chloride (cationic monomer), 0.011 parts of ammonium persulfate (initiator), 0.005 parts of sodium bisulfite (initiator) Mix with water; add 1.88 parts of hydrochloric acid to adjust the pH value to 7, add 0.94 parts of glacial acetic acid to adjust the pH value to 4, and polymerize in a water bath at 35°C for 15 minutes to obtain a polymer solution with a certain viscosity. Add 1.93 parts of NaOH to adjust the pH value to 9, polymerize at 75°C for 7 hours, take it out and cool it, and obtain a cementitious gel plugging material.

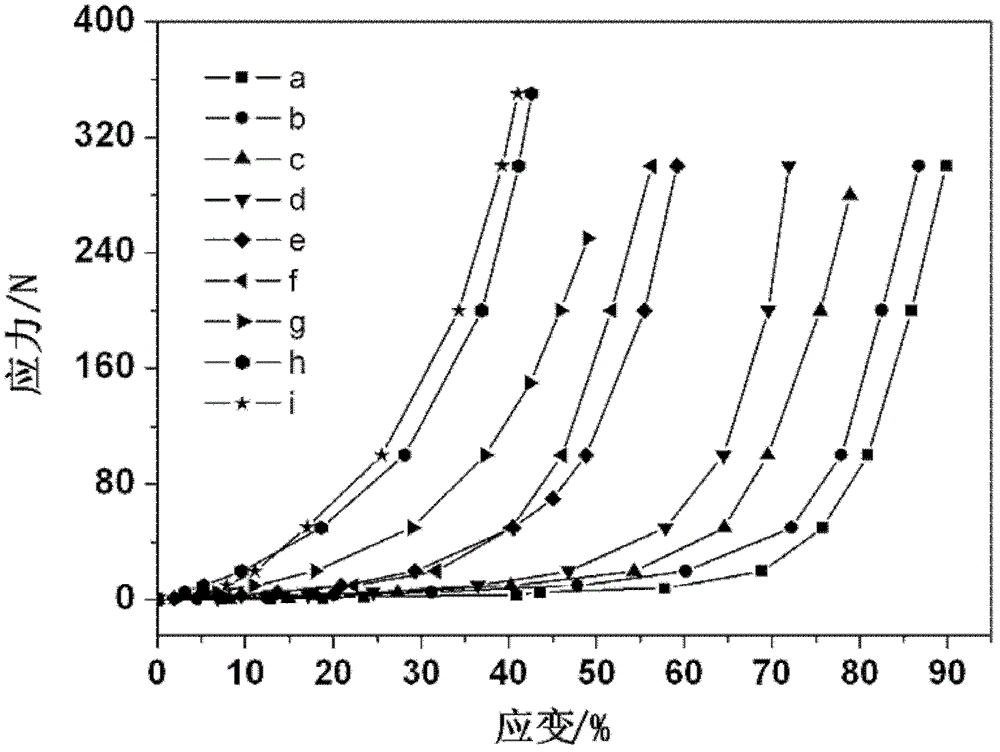

[0022] figure 1 It is the stress-strain diagram of the cementing plugging material prepared in Example 1 continuing to react in an oil bath at 100°C for different times. It can be seen from the figure that the stress required for the same strain to occur in the present invention increases with the prolongation of the reaction time. As the valu...

Embodiment 2

[0025] Mix 36 parts of sulfonated melamine, 22.8 parts of acrylamide, 1.2 parts of trimethylallyl ammonium chloride (cationic monomer), 0.015 parts of ammonium persulfate (initiator), 0.008 parts of sodium sulfite (initiator) and water ;Add 1.88 parts of hydrochloric acid to adjust the pH value to 7, add 0.94 parts of glacial acetic acid to adjust the pH value to 4, and polymerize in a water bath at 35°C for 15 minutes to obtain a polymer solution with a certain viscosity. Add 3.24 parts of Adjust the pH value to 12 with NaOH, polymerize at 60°C for 10 hours, take it out and cool it, and obtain a cementitious gel plugging material.

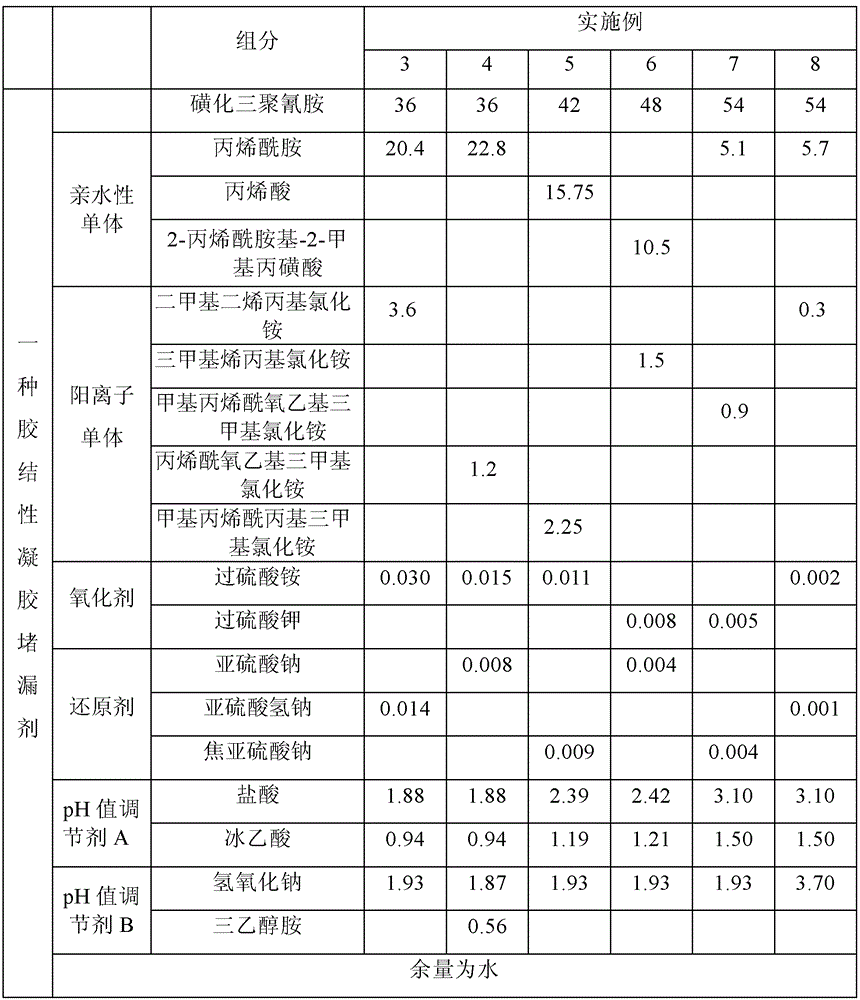

[0026] Other specific examples 3-8 were prepared according to the components given in Table 1.

[0027] Table 1 A kind of cementing gel plugging agent embodiment (unit is by mass percentage)

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com