Fire-retarding-type fire inhibiting hard polyether polyol and preparation method thereof

A polyether polyol, rigid technology, applied in the field of preparation of flame retardant grade flame retardant rigid polyether polyol, can solve the problems of tribromostyrene synthesis difficulty, foaming equipment corrosion, thermal instability, etc. Achieve the effects of small flame spread, strong flame penetration and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

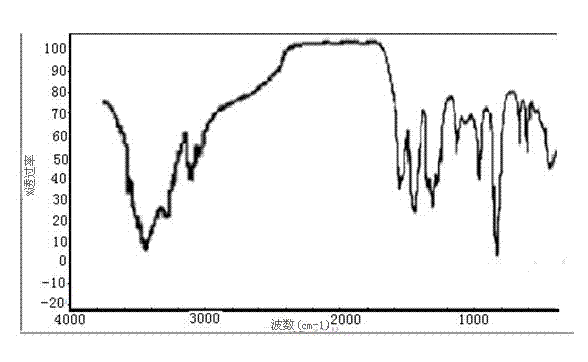

Method used

Image

Examples

Embodiment 1

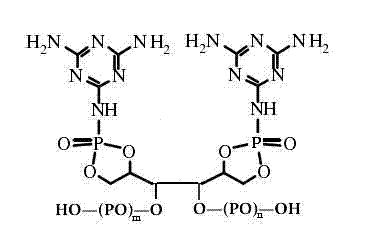

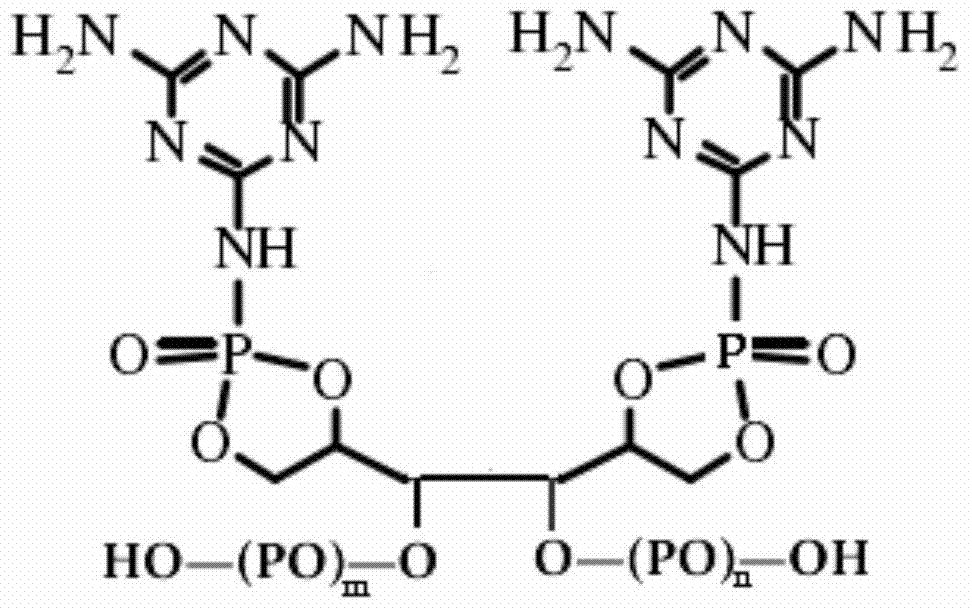

[0022] The flame retardant grade flame retardant rigid polyether polyol of the present invention, its main structural formula is:

[0023] ,

[0024] Wherein, the value of m is 2~5, and the value of n is 2~5.

[0025] The above-mentioned flame-retardant grade flame-retardant rigid polyether polyol is prepared from sorbitol, melamine, and phosphorus oxychloride under the action of zinc chloride as a catalyst, and then added to propylene oxide at a certain temperature and pressure.

[0026] The specific operation steps are:

[0027] (1) Add 272g of sorbitol and 400mL of benzene into a 2L reactor equipped with a reflux condensing device, start stirring and dissolving, introduce nitrogen gas, and heat the oil bath to 80°C. Add 250g of phosphorus oxychloride quickly and then slowly within 5h. After the addition is complete, add 1g of diethylamine and reflux for 2h. When no HCl gas is released and the reaction solution becomes clear, add melamine and use diethylamine as the acid...

Embodiment 2

[0032] In this embodiment, the flame-retardant grade flame-retardant rigid polyether polyol has the same molecular formula as in Example 1, and sorbitol, melamine, and phosphorus oxychloride are added to propylene oxide under the action of catalyst zinc chloride, Made under certain temperature and pressure.

[0033] The specific operation steps are:

[0034] (1) Add 300g of sorbitol and 400mL of benzene into a 2L reactor equipped with a reflux condensing device, start stirring and dissolving, introduce nitrogen gas, and heat the oil bath to 80°C. Add 275g of phosphorus oxychloride quickly and then slowly within 5h. After the addition is complete, add 1g of diethylamine and reflux for 2h. When no HCl gas is released and the reaction solution becomes clear, add melamine and use diethylamine as the acid binding agent. Agent, benzene as solvent, heat preservation and reflux. After reacting for 0.5~2H, put the material into the filter tank, cool and filter, wash with dichlorometh...

Embodiment 3

[0037] In this embodiment, the flame-retardant grade flame-retardant rigid polyether polyol has the same molecular formula as in Example 1, and sorbitol, melamine, and phosphorus oxychloride are added to propylene oxide under the action of catalyst zinc chloride, Made under certain temperature and pressure.

[0038] The specific operation steps are:

[0039](1) Add 240g of sorbitol and 400mL of benzene into a 2L reactor equipped with a reflux condensing device, start stirring and dissolving, then introduce nitrogen gas, and heat the oil bath to 80°C. Add 306g of phosphorus oxychloride quickly and then slowly within 5h. After the addition is complete, add 1g of diethylamine and reflux for 2h. When no HCl gas is released and the reaction solution becomes clear, add melamine and use diethylamine as the acid binding agent. Agent, benzene as solvent, heat preservation and reflux. After reacting for 0.5~2H, put the material into the filter tank, cool and filter, wash with dichloro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com