Process for preparing high-activity semi-hydrated gypsum cementing material and gypsum product by aid of phosphorous gypsum

A technology of hemihydrate gypsum and cementitious materials, applied in the field of production of gypsum cementitious materials and gypsum products, can solve the problems of high production energy consumption, high investment, high production cost, etc., and achieve saving of operating costs, easy process control, and reliability increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

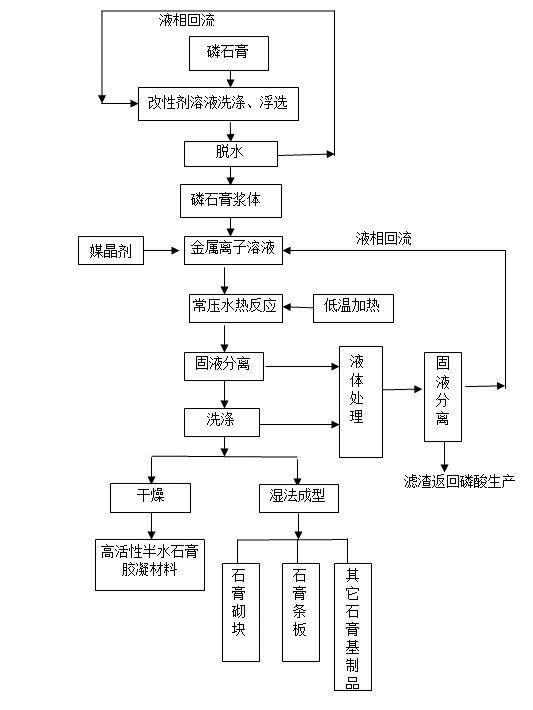

Method used

Image

Examples

Embodiment 1

[0026] A kind of technology that phosphogypsum prepares highly active hemihydrate gypsum cementitious material, it comprises following process:

[0027] 1) Phosphogypsum pretreatment process: The phosphogypsum used in this example is a by-product of wet-process phosphoric acid production. The soluble fluorine content is 0.21%, the organic matter content is 0.12%, and the phosphogypsum is washed with saturated lime water and floated until the phosphogypsum has a soluble phosphorus content of 0.095%, a soluble fluorine content of 0.05%, and an organic matter content of 0.01%, and dehydrates to obtain a phosphogypsum slurry;

[0028] 2) Atmospheric pressure hydrothermal reaction process: add the pretreated phosphogypsum slurry and crystallization agent to the calcium chloride solution with a concentration of 2.0mol / L to form a slurry, and the phosphogypsum and calcium chloride solution in the slurry The mass ratio of phosphogypsum is 1:9~3:2, and the crystallization agent is succ...

Embodiment 2

[0035] A process for preparing highly active hemihydrate gypsum cementitious material from phosphogypsum, the preparation steps are basically the same as in Example 1, the difference from Example 1 is that the mass percentage of phosphogypsum and calcium chloride solution is kept at 1:1, Stirring paddle rotating speed is 200rpm, change successively the molar concentration of calcium chloride, the temperature of reaction temperature, the temperature of washing hot water and the drying temperature of slurry in the solution of serial number 3 sample preparation process of embodiment 1, calcium chloride solution concentration, D Table 2 shows the comparison of the dosage of diacid mordant, reaction time and product dry compressive strength.

[0036] Table 2 Calcium chloride molar concentration, succinic acid dosage, reaction time and product dry compressive strength result comparison

[0037]

Embodiment 3

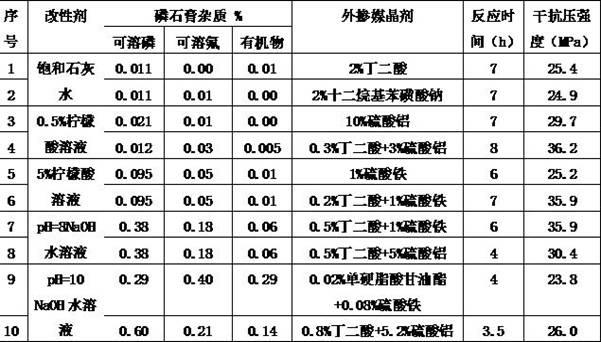

[0039] A process for preparing highly active hemihydrate gypsum cementitious material from phosphogypsum, the preparation steps are basically the same as in Example 1, the difference from Example 1 is that the mass ratio of phosphogypsum to calcium chloride solution is kept at 1:1, The rotation speed of the stirring blade is 200rpm, and the number 3 sample preparation process of Example 1 is changed in turn. The type of modifier and the preparation process 2) The type and dosage of the crystallization agent, and the impurity content of phosphogypsum after pretreatment , Mordant and product dry compressive strength results are compared in Table 3.

[0040] Table 3 Comparison of results of phosphogypsum impurity content, mordant and product dry compressive strength after pretreatment

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com