Sewage treatment method based on blasting laminated artificial wetland

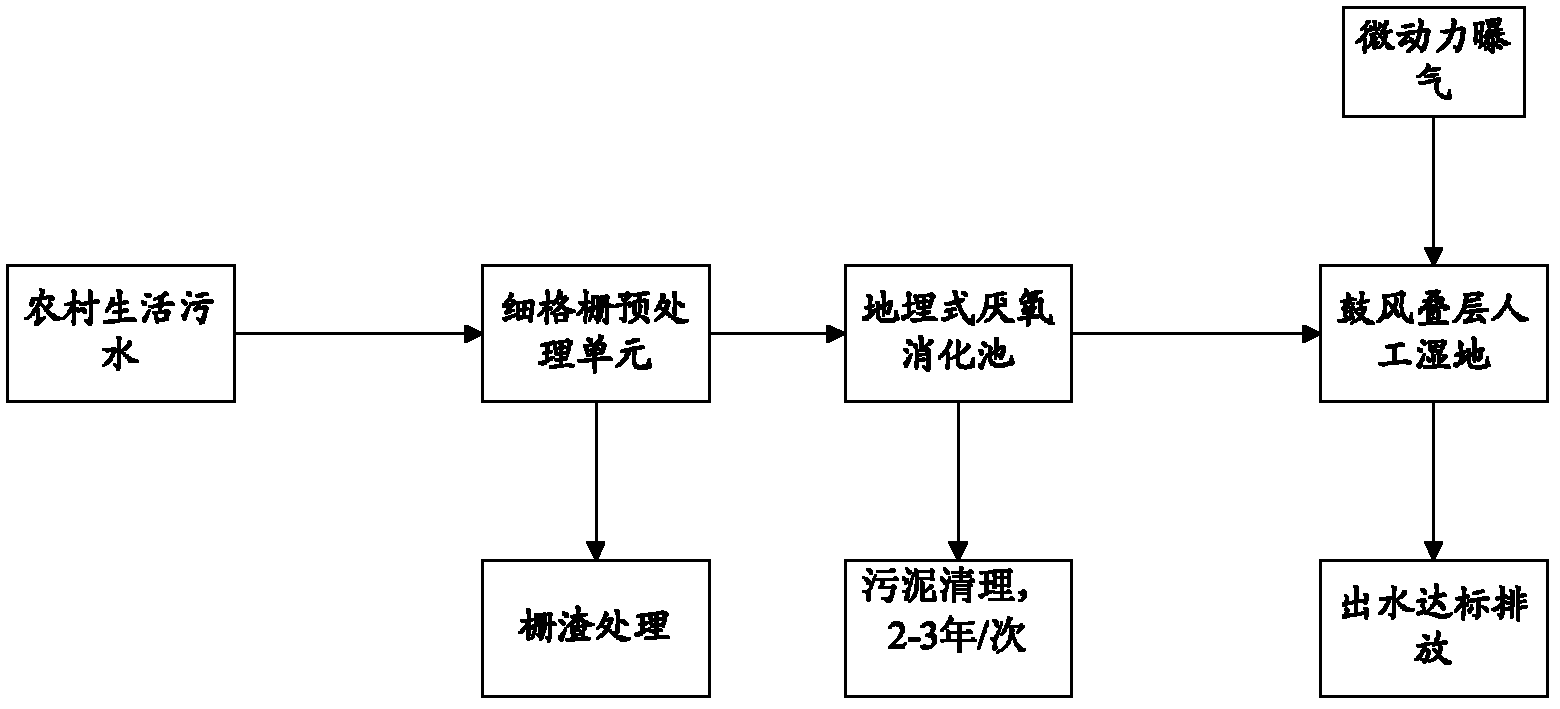

A sewage treatment method and a technology for constructed wetlands, which are applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., which can solve the problem that the overlap cannot be effectively utilized and the total nitrogen removal effect of sewage is limited. , unsatisfactory sewage treatment effect, etc., to achieve good denitrification and phosphorus removal capacity, improve organic matter and ammonia nitrogen removal capacity, and improve the effect of effluent quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

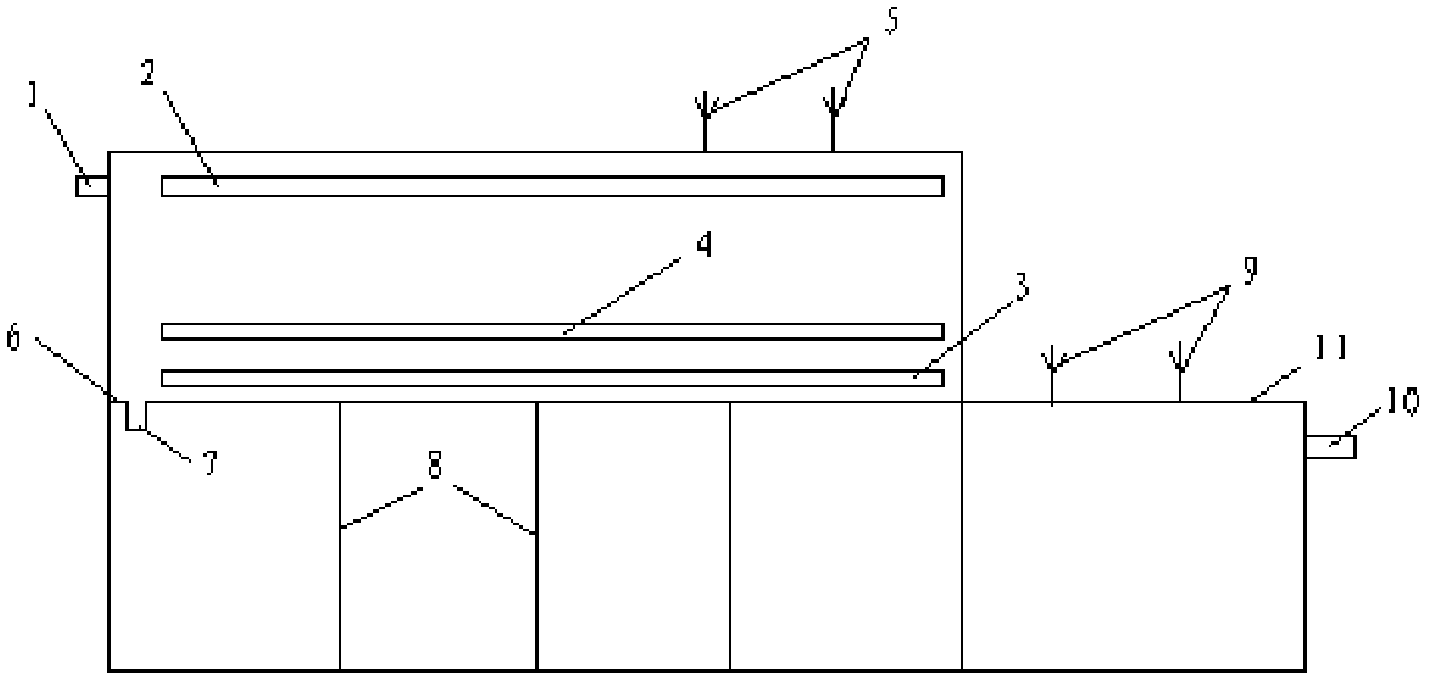

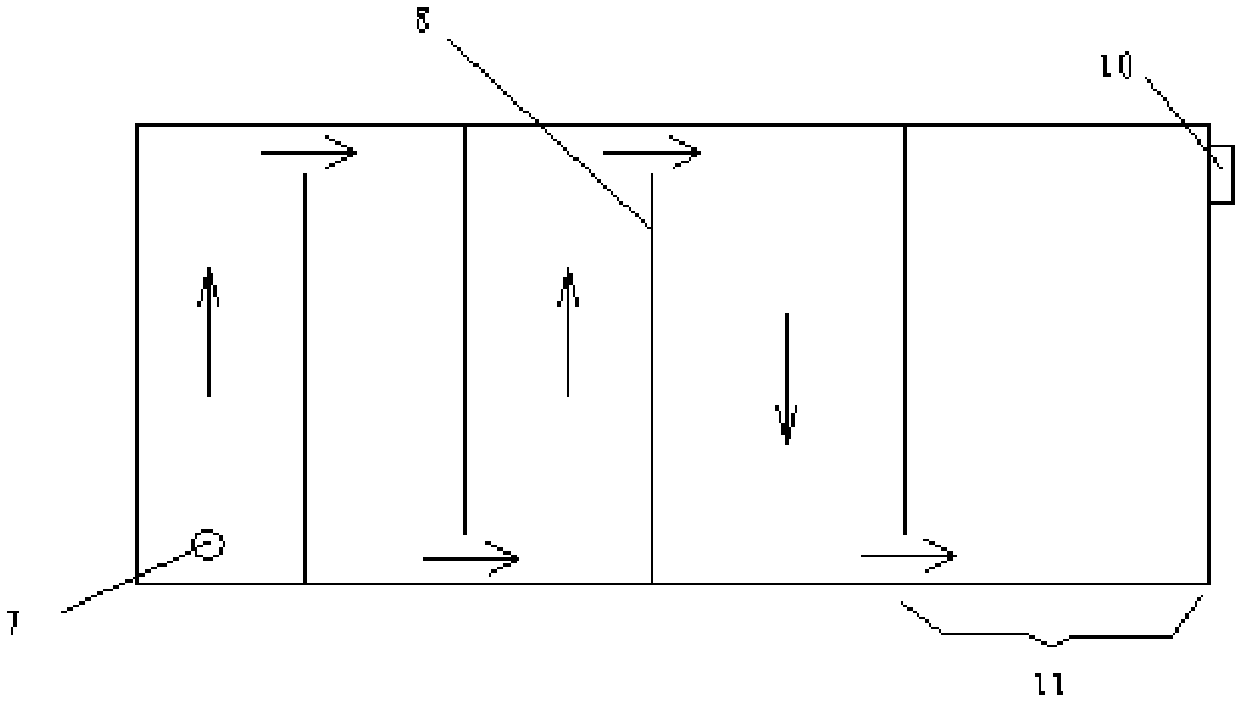

[0040] Adopt the method of the present invention to process certain rural domestic sewage, the CODcr of this rural domestic sewage is 225mg / L, ammonia nitrogen (NH 3 -N) concentration is 23.5mg / L, total nitrogen (TN) concentration is 33.7mg / L, total phosphorus (TP) concentration is 2.0mg / L, the fine grid pretreatment unit adopts the ditch with fine grid, its The inclination angle of the fine grid is 45°, the gap is 20mm, the flow velocity of the sewage in the ditch is 0.5m / s, and the flow velocity through the fine grid is 0.7m / s. The buried anaerobic digester adopts a concrete structure. For a spherical pool, set a water outlet hole at a distance of 30cm from the top of the buried anaerobic digestion tank. The flow rate of the sewage passing through the water outlet hole is 0.5m / s. The lower packing support is set at the bottom 35cm, and the elastic three-dimensional packing is fixed and suspended between the upper and lower two packing supports. The filling rate of the packin...

Embodiment 2

[0044] Adopt the method of the present invention to process certain rural domestic sewage, this rural domestic sewage CODcr is 258mg / L, and ammonia nitrogen (NH 3 -N) concentration is 28.0mg / L, total nitrogen (TN) concentration is 37.5mg / L, total phosphorus (TP) concentration is 1.8mg / L, the fine grid pretreatment unit adopts the ditch with fine grid, its The inclination angle of the fine grid is 60°, the gap is 25mm, the flow velocity of the sewage in the ditch is 0.6m / s, and the flow velocity through the fine grid is 0.85m / s. The buried anaerobic digester adopts a concrete structure. For a spherical pool, a water outlet hole is set at a distance of 30cm from the top of the buried anaerobic digestion tank. The flow rate of the sewage passing through the water outlet hole is 0.6m / s. The lower packing support is set at the bottom 35cm, and the elastic three-dimensional packing is fixed and suspended between the upper and lower two packing supports. The filling rate of the packi...

Embodiment 3

[0048] Adopt the method of the present invention to handle certain rural domestic sewage, this rural domestic sewage CODcr is 315mg / L, and ammonia nitrogen (NH 3 -N) concentration is 20.8mg / L, total nitrogen (TN) concentration is 30.5mg / L, total phosphorus (TP) concentration is 1.5mg / L, the fine grid pretreatment unit adopts the ditch with fine grid, its The inclination angle of the fine grid is 60°, the gap is 16mm, the flow velocity of the sewage in the ditch is 0.7m / s, and the flow velocity through the fine grid is 0.9m / s. The buried anaerobic digester adopts a concrete structure For a spherical pool, set a water outlet hole at a distance of 30cm from the top of the buried anaerobic digestion tank. The flow rate of the sewage passing through the water outlet hole is 0.5m / s. Set the lower packing support at the bottom 35cm, and fix and hang the elastic three-dimensional packing between the upper and lower packing supports. The filling rate of the packing is 75%, and the resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com