Pneumatic conveying device for conveying laminar materials

A pneumatic conveying, sheet-like technology, applied in conveying bulk materials, conveyors, transportation and packaging, etc., which can solve the problems of difficult cutting, unsuitable for large-scale industrial production, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

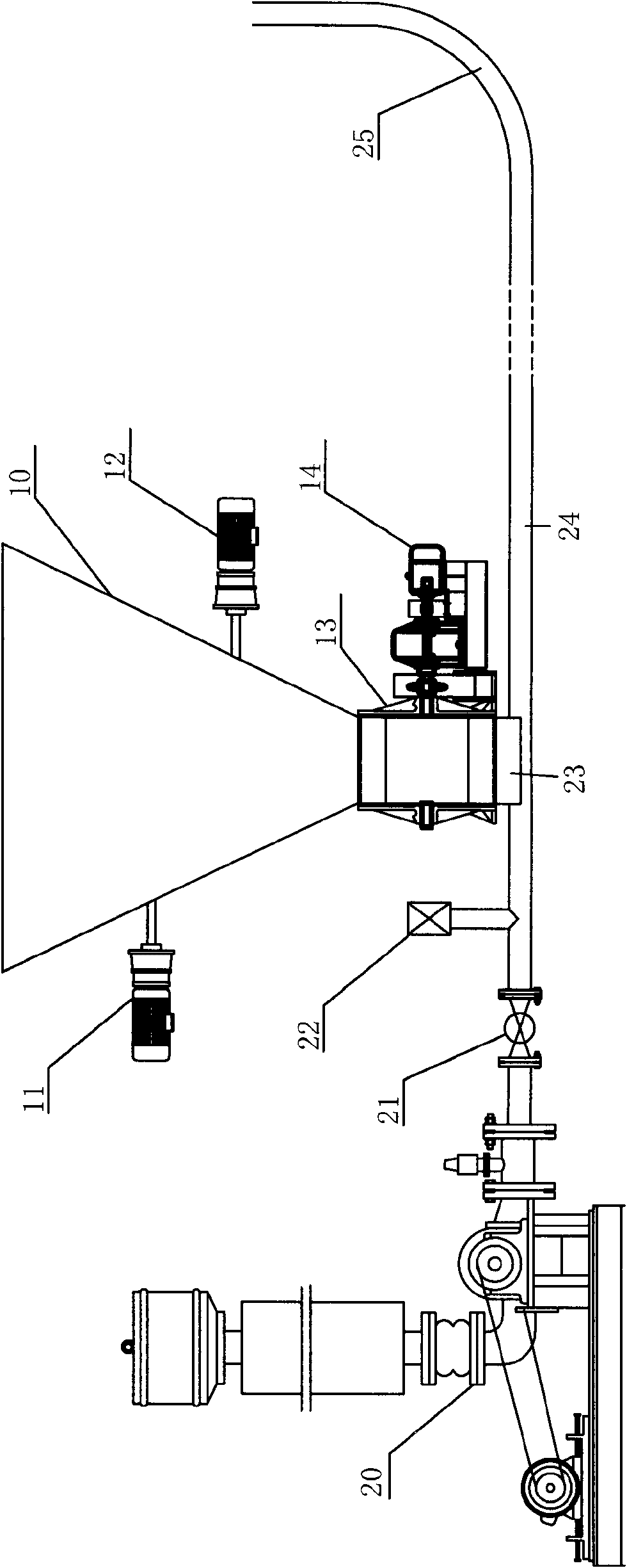

[0032] The pneumatic conveying device for transporting flake materials provided by the invention solves the problem that flake materials such as glass fiber reinforced plastics which replace fuel are difficult to convey.

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0034] Metering lock air feeding system:

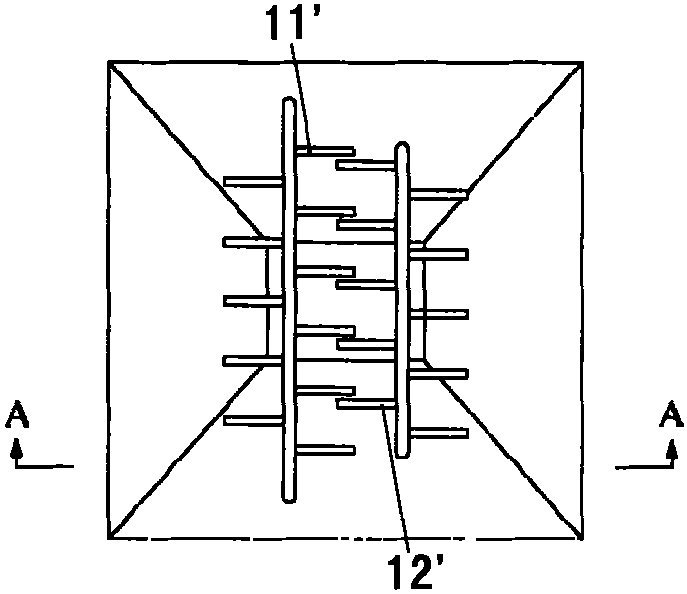

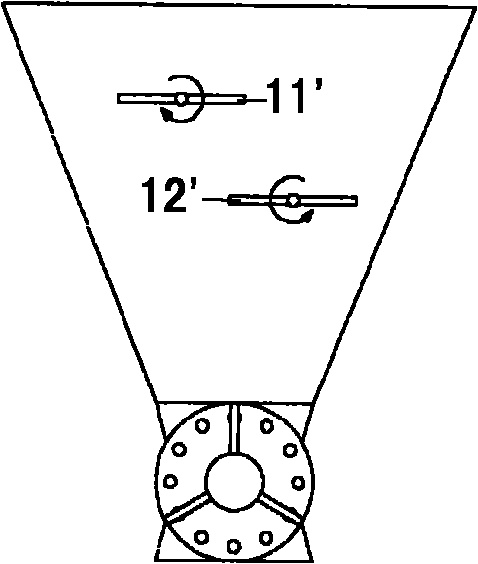

[0035] The metering lock air feeding part is composed of the following parts: buffer feeding bin 10, two-stage feeding device 11, 12, rotary feeding device 13, motor and reducer matched with feeding device and rotary feeding device 14.

[0036] The crushed flake materials with an average particle size of less than 20 mm first enter the buffer lower hopper, which is in the shape of an inverted square. Because the broken glass fiber reinforced plastics are prone to sticking and cause material bridging, there is a corrugated liner (not shown in the figure) inside the buffer lower silo. The form of the liner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com