Catalyst for preparing iso-olefins by isomerizing straight-chain olefins and preparation method of catalyst

A straight-chain olefin and catalyst technology, applied in the field of catalyst and its preparation, can solve the problems of low catalyst reaction activity, low selectivity of target product, poor catalyst stability, etc., to maintain long-term stability, good technical effect, improve Effects of activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

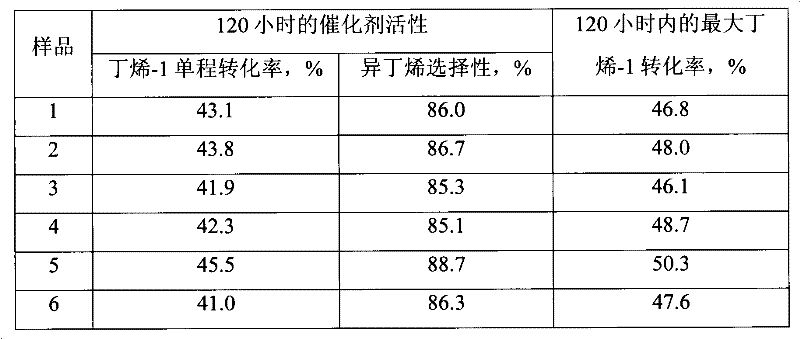

Examples

Embodiment 1

[0029] Ratio of silicon to aluminum (SiO 2 / Al 2 o 3 ) (mole) is 901 grams of ferrierite raw powder of 20, 107 grams of aluminum sol, 15 grams of citric acid, 203 grams of deionized water are mixed uniformly, and then shaped after stirring at a constant speed for 30 minutes, and then dried at 100 ° C for 20 hours, Catalyst sample 1 was obtained after calcining at 500° C. for 2 hours.

Embodiment 2

[0031] Ratio of silicon to aluminum (SiO 2 / Al 2 o 3 ) (mole) is 885 grams of Ferrierite raw powder of 20, 93 grams of aluminum sol, 16 grams of citric acid, and 196 grams of deionized water are mixed evenly, and then shaped after stirring at a constant speed for 30 minutes, and then dried at 100 ° C for 20 hours. Then bake at 500°C for 2 hours. The catalyst obtained after roasting is immersed in palladium nitrate aqueous solution (the weight concentration of palladium is 5%) at 60 ℃ for 3 hours, wherein the ratio (weight) of catalyst and palladium nitrate aqueous solution is 2; the mixture of heating evaporation catalyst and palladium nitrate solution , and then dried at 100°C for 20 hours, and then calcined at 500°C for 2 hours to obtain catalyst sample 2.

Embodiment 3

[0033] Ratio of silicon to aluminum (SiO 2 / Al 2 o 3) (mol) is 916 grams of Ferrierite raw powder of 20, 111 grams of aluminum sol, 18 grams of citric acid, and 213 grams of deionized water are mixed uniformly, stirred at a constant speed for 30 minutes, then formed, and then dried at 100° C. for 20 hours. Then bake at 500°C for 2 hours. The catalyst obtained after roasting is immersed in cobalt nitrate aqueous solution (the weight concentration of cobalt is 5%) at 60 ℃ for 3 hours, wherein the ratio (weight) of catalyst to cobalt nitrate aqueous solution is 2; the mixture of heating evaporation catalyst and cobalt nitrate solution , and then dried at 100°C for 20 hours, and then calcined at 500°C for 2 hours to obtain catalyst sample 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com