Device capable of completely eliminating wall flow effect and integrated with tower body and method for mounting device

A technology that completely eliminates wall flow effects, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc., can solve problems affecting separation effect, backmixing, wall flow, etc. Efficiency, easy processing, simple material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

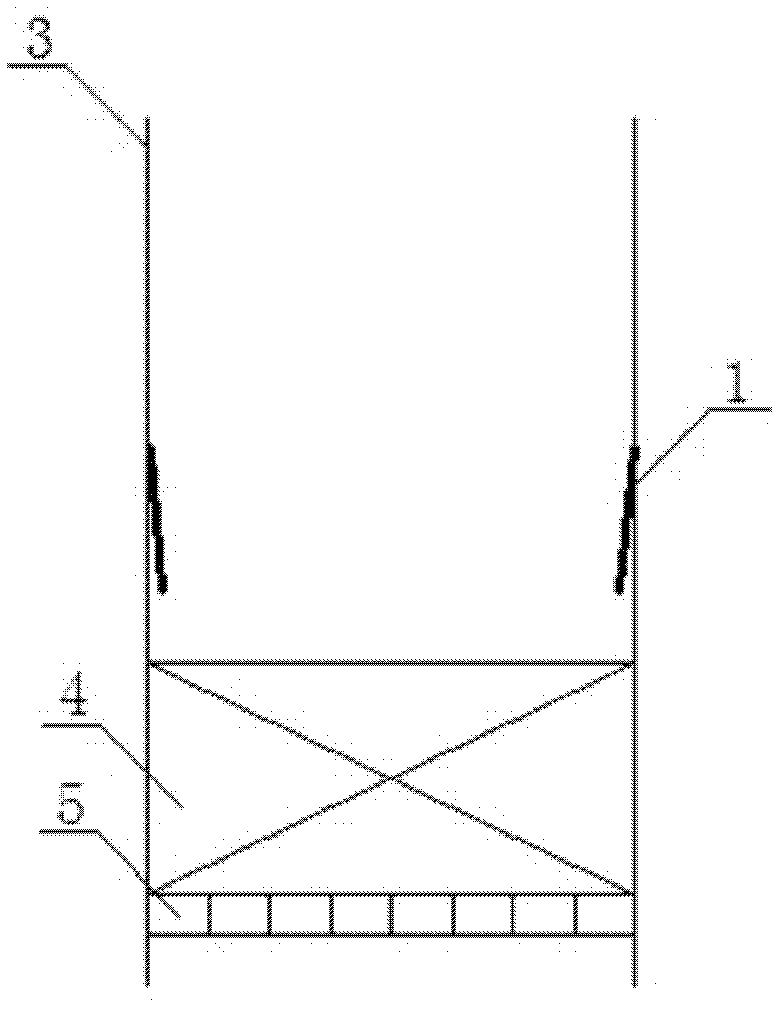

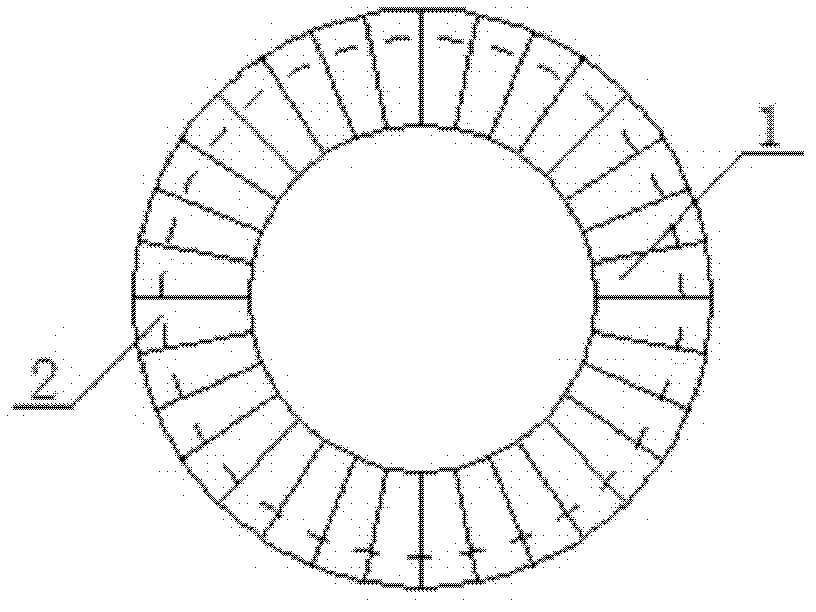

[0037] The liquid receiving ring 1 selects a stainless steel sheet that meets the GB / T G3280-2007 standard, with a length of 1200mm, a width of 75mm, and a thickness of 0.2mm. The lower part has an opening width of 20mm and an opening depth of 35mm, and is welded to the inner wall of the tower. The liquid redistribution ring 2 also chooses GB / T G3280-2007 standard stainless steel thin steel sheet, the cylinder height is 35mm, the circumference is 1200mm, and the bottom ring is 10mm wide.

[0038] This device is used in a rectification tower with an inner diameter of 380mm. The height of each section of packing is 100mm. Each section of packing is equipped with this device. The height of the packing layer is 1000mm. 350Y stainless steel structured packing is used. The rectification tower separates the benzene-ethylbenzene mixture. First of all, this device is not used, and only the above-mentioned packing is used. The wall flow is about 37.9%. After using this device, no wall flow ...

Embodiment 2

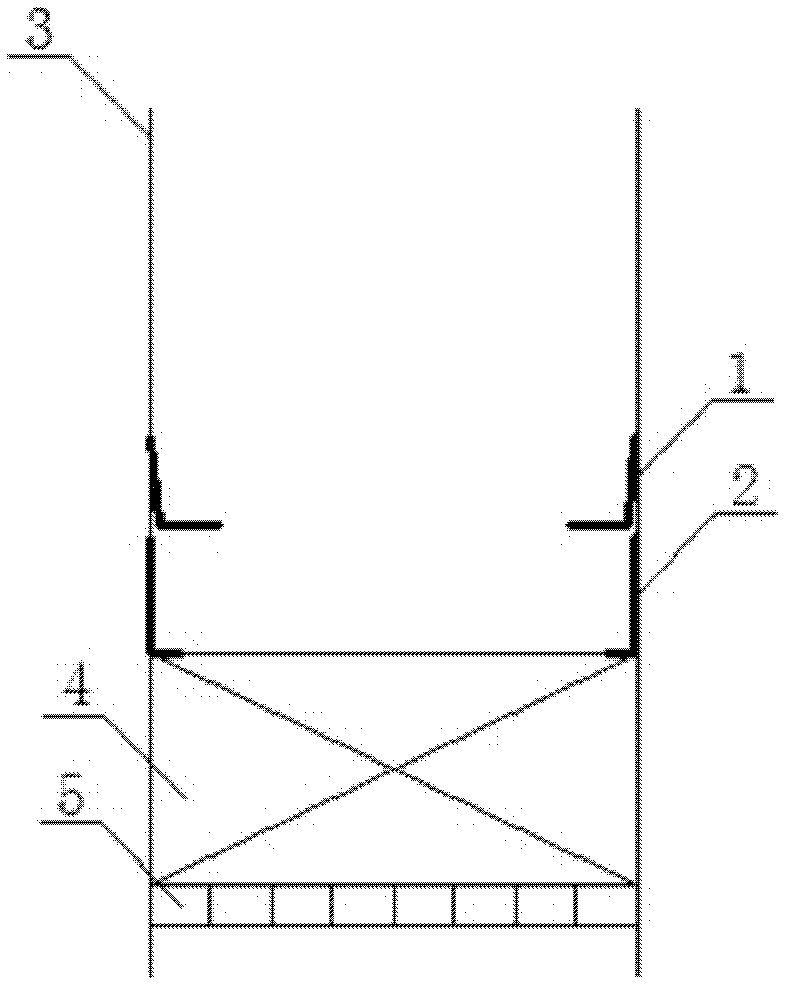

[0040] The liquid receiving ring 1 selects a stainless steel sheet that meets the GB / T G3280-2007 standard, with a length of 3160mm, a width of 200mm, and a thickness of 0.2mm. The lower part has an opening width of 30mm and an opening depth of 90mm, and is welded to the inner wall of the tower. The liquid redistribution ring 2 also chooses GB / T G3280-2007 standard stainless steel thin steel sheet, the cylinder height is 130mm, the circumference is 3160mm, and the bottom ring is 15mm wide.

[0041] This device is used in a rectification tower with an inner diameter of 1000mm. The height of each section of the packing is 300mm. Each section of the packing is equipped with this device. The height of the packing layer is 6000mm. The 250Y stainless steel structured packing is used. The distillation column separates the ethanol-water mixture. First of all, this device is not used, only the above-mentioned packing is used, and there is about 28.6% wall flow. After using this device, no ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com