Cellulose diacetate for retardation film

A technology of cellulose diacetate and phase difference film, which is applied in the direction of instruments, optics, optical components, etc., can solve the problems of inability to achieve uniform chemical composition and uneven molecular weight distribution, achieve uneven molecular weight distribution, reduce bright spot foreign matter, chemical Composition of uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0148] The hardwood prehydrolyzed kraft pulp with an α-cellulose content of 98.4% by weight was pulverized into a cotton form with a disc refiner. 26.8 parts by weight of acetic acid were sprayed into 100 parts by weight of pulverized pulp (moisture content 8%), stirred and mixed sufficiently, and then pretreated by standing for 60 hours and activated (activation step). The activated pulp was added to a mixture containing 323 parts by weight of acetic acid, 245 parts by weight of acetic anhydride, and 13.1 parts by weight of sulfuric acid, and the acetylation was carried out for 90 minutes by adjusting the maximum temperature from 5°C to 40°C over 40 minutes. A neutralizing agent (24% magnesium acetate aqueous solution) was added over 3 minutes, and the amount of sulfuric acid (the amount of aged sulfuric acid) was adjusted to 2.5 parts by weight. Furthermore, after raising the temperature of the reaction bath to 75° C., water was added to set the reaction bath moisture (cured...

Embodiment 2~6、8、9、12~13

[0149] (Examples 2~6, 8, 9, 12~13 and comparative examples 1~7, 9, 11~12)

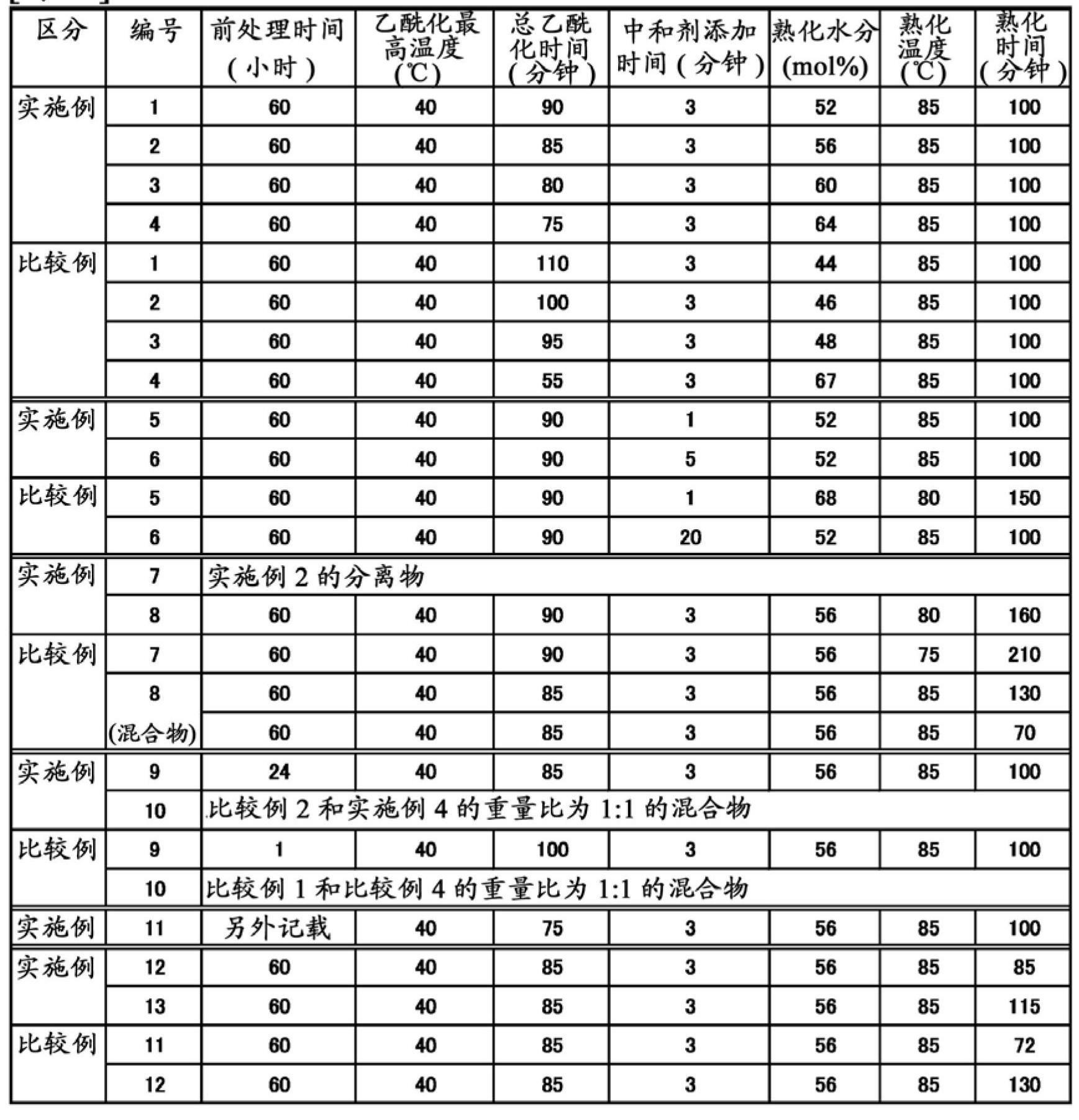

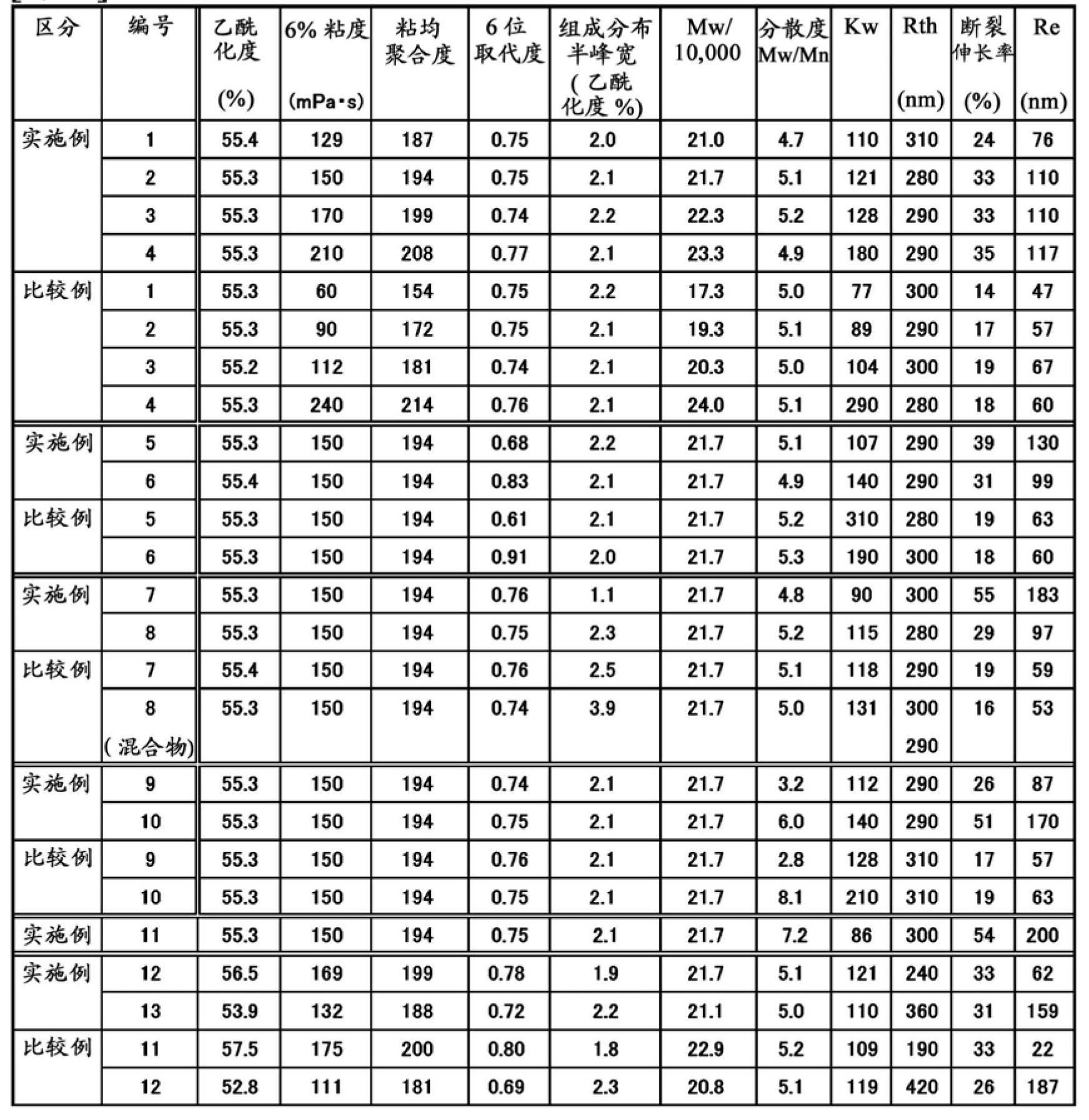

[0150] The preparation conditions of cellulose acetate are shown in Table 1. Under the conditions shown in Table 1, the same operation as in Example 1 was carried out to obtain cellulose diacetate.

[0151] [Table 1]

[0152]

Embodiment 7

[0154] Purification of cellulose diacetate

[0155] Disperse 100 parts by weight of the mixture containing cellulose diacetate obtained in Example 2 in 1,000 parts by weight of dichloromethane at room temperature (about 22° C.) Centrifugation was performed to obtain a gel-like precipitate. The gel-like precipitate was dispersed in 2,000 parts by weight of methanol, and centrifuged under the above conditions to obtain a precipitate. This methanol was washed twice. Furthermore, washing|cleaning was carried out twice using 50 weight% acetone aqueous solution instead of methanol. Thereafter, it was washed twice with 1,000 parts by weight of water, dried under reduced pressure at 40° C. until it became a constant weight, and 61 parts by weight of purified cellulose diacetate was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| degree of acetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com