High-temperature solar thermochemical tail gas treatment integrated heat recovery and filtration system

A technology for solar thermal and exhaust gas treatment, applied in gas treatment, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems of low cost of filtration and heat storage and recovery capabilities, avoid frequent ash cleaning operations, and have a wide range of applications , Reduce the effect of irreversible loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

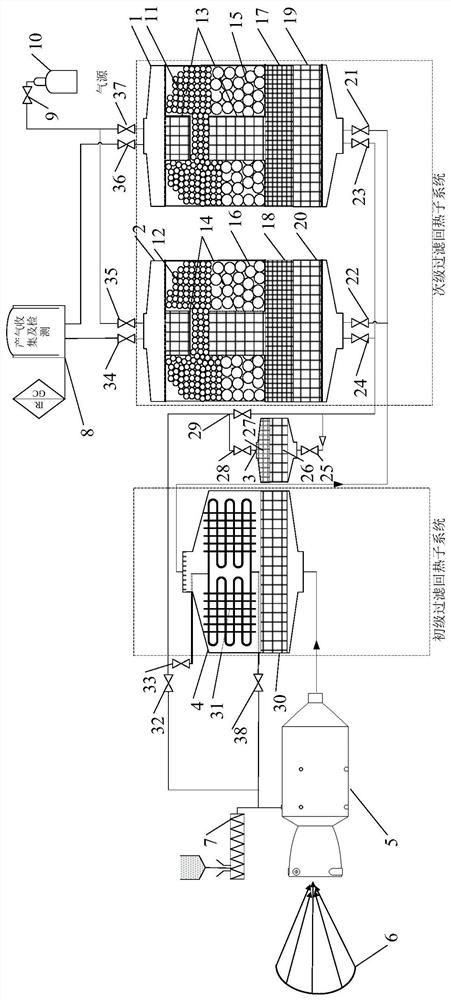

[0037] figure 1 It is a schematic diagram of the structure and work flow of the regenerative filtration integrated system in Example 1 of the present invention. like figure 1 As shown, the heat recovery and filtration integrated system includes a primary filter heat recovery subsystem, a secondary filter heat recovery subsystem, a blowback filter, and pipelines. The primary filter heat recovery subsystem, the secondary filter heat recovery subsystem and the blowback filter are connected in sequence through pipelines.

[0038] The primary filtration heat recovery subsystem includes at least a fourth heat storage tank 4 wrapped with an insulation layer, the tank body is cylindrical, and the bottom and top of the tank body are shrinkage sections that play the role of diverting and collecting filter particles. The small mouth end of the bottom s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com