Power module group of high-power current-converting equipment

A technology of equipment power and power modules, which is applied to output power conversion devices, electrical components, cooling/ventilation/heating transformation, etc., can solve the problems of large energy consumption and long wind range, and achieve low energy consumption of air cooling The effect of short distance and small temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

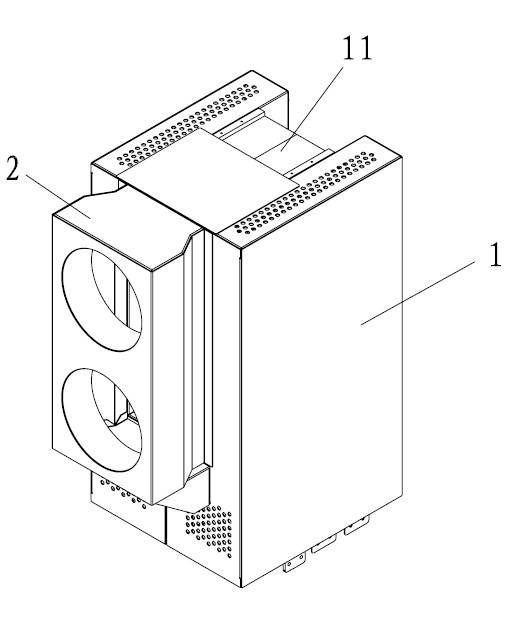

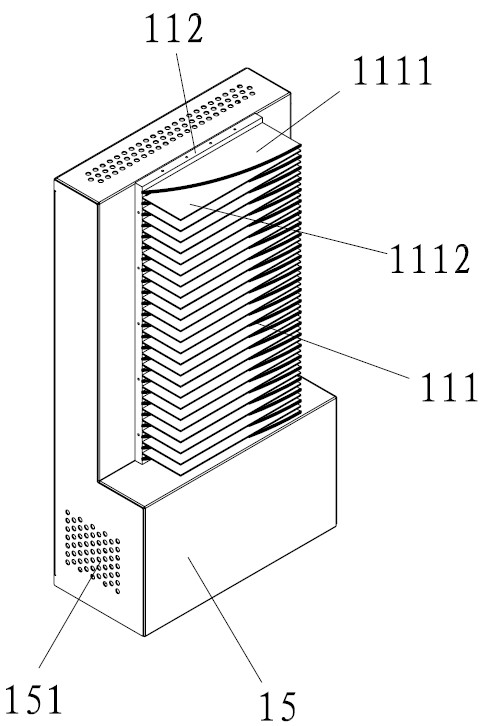

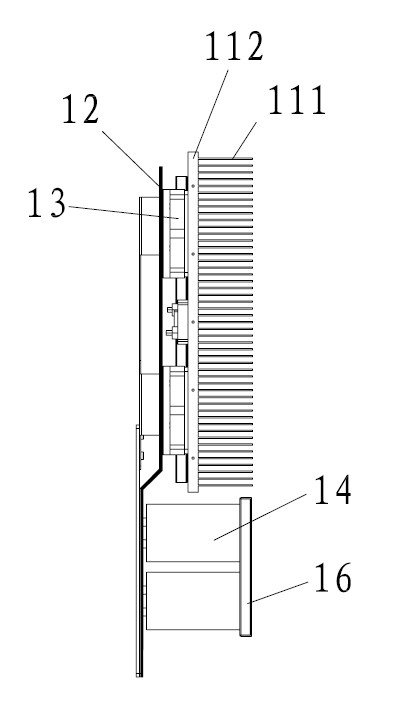

[0039] Embodiment 1: as Figures 1 to 3 As shown, a power module group of high-power converter equipment includes two power modules 1 distributed side by side. The power module 1 includes a casing 15, a laminated busbar 12 fixed to the inner wall of the casing 15, The upper IGBT component 13, the capacitor support plate 16 fixed on the other inner wall of the housing 15, the capacitor component 14 fixedly connected between the laminated busbar 12 and the capacitor support plate 16, and the IGBT component 13 are fixedly connected to the IGBT component 13 Radiator 11 for dissipating heat.

[0040] The casing 15 is located at the position of the capacitor assembly 14 and is provided with cooling holes 151 for the cooling of the capacitor assembly 14 . In order to achieve a better heat dissipation effect, a fan can also be fixed at the position of the casing 15 provided with the cooling holes 151 .

[0041]The heat sink 11 includes a heat dissipation plate 112 fixedly connected t...

Embodiment 2

[0043] Embodiment 2: The difference with Embodiment 1 is that, as Figure 4 As shown, the side of the fan fin 1111 that is farther away from the heat dissipation plate 112 in the length direction includes a straight section 11111 parallel to the heat dissipation plate 112, and a slow temperature section 11112 where the distance between the fan fin 1111 and the heat dissipation plate 112 gradually decreases along the wind direction of the fan 2; The slow temperature section 11112 is arc-shaped.

Embodiment 3

[0044] Embodiment 3: The difference from Embodiment 1 is that the heat dissipation fins 111 are fan fins 1111, and the distance between the side of the fan fins 1111 that is farther away from the heat dissipation plate 112 in the length direction and the heat dissipation plate 112 is gradually along the wind direction of the fan 2. increase; and the side of the fan fin 1111 that is farther away from the heat dissipation plate 112 in the length direction is arc-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com