Method for preparing active electrode material of lithium ion battery

An active electrode material and a technology for lithium-ion batteries, which are applied in the fields of chemical engineering and energy and chemical industry, can solve the problems of the tap density of electrode materials and the adverse effects of energy density, and achieve high current charge and discharge performance, improve energy density, and process process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

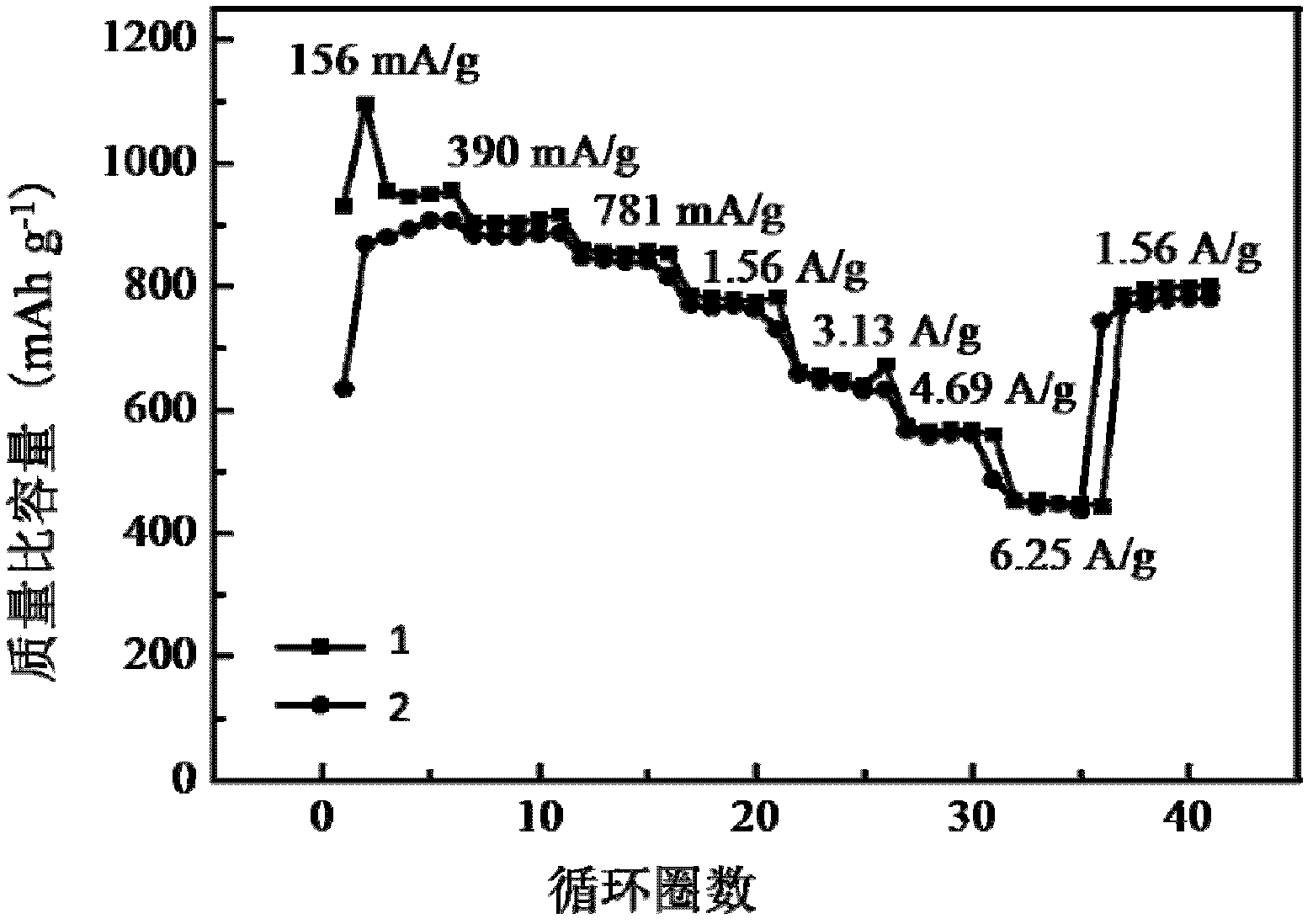

Embodiment 1

[0030] in H 2 O solution, FeCl was added in a molar ratio of 2:1 3 and FeCl 2 4H 2 O, stir evenly, quickly add 28% ammonia water, react for 30 minutes to get 3-12nm Fe 3 o 4 Nanocrystalline grains, the preparation mass percentage content is 1.0% Fe 3 o 4 aqueous solution. Add 2.0% sucrose and 2.0% polyvinyl alcohol into the above solution, and stir evenly to form a mixed liquid solution. The above mixture solution is sprayed and granulated with a gasification spray device at a temperature of 450°C to obtain spherical particles, and these spherical particles are further annealed at 600°C in nitrogen to obtain carbon / Fe 3 o 4 Negative material. attached figure 2 Scanning electron micrographs show that these Fe 3 o 4 The nanograins assemble into a continuous porous carbon framework to form micron-sized spherical particles. The carbon / Fe 3 o 4 The negative electrode material is made into the negative electrode of the lithium-ion battery, and the electrochemical per...

Embodiment 2

[0032] in H 2 O solution, FeCl was added in a molar ratio of 2:1 3 and FeCl 2 4H 2 O, stir evenly, quickly add 28% ammonia water, react for 30 minutes to get 3-12nm Fe 3 o 4 Nanocrystalline grains, the preparation mass percentage content is 0.6% Fe 3 o 4 aqueous solution. The above solution was added with 0.1% by mass of sucrose, 0.2% of dispersed natural graphite and 3.0% of block copolymer F127, and stirred evenly to form a uniform mixture solution. The above mixture solution was subjected to spray granulation with a gasification spray device at a temperature of 400° C. to obtain spherical particles. These spherical particles were further annealed at 600 °C in nitrogen to obtain porous graphite-coated Fe 3 o 4 Negative active material. The graphite-coated Fe 3 o 4 The negative electrode material is made into the negative electrode of the lithium-ion battery, and the electrochemical test is carried out.

Embodiment 3

[0034] in H 2 O solution, FeCl was added in a molar ratio of 2:1 3 and FeCl 2 4H 2 O, stir evenly, quickly add 28% ammonia water, react for 30 minutes to get 3-12nm Fe 3 o 4 Nanocrystalline grains, the preparation mass percentage content is 2.0% Fe 3 o 4 aqueous solution. The above solution was added with 1.0% by mass of sucrose, 0.1% of carbon nanotubes and 0.5% of block copolymer P123, and stirred evenly to form a uniform mixture solution. The above mixture solution was subjected to spray granulation with a gasification spray device at a temperature of 500° C. to obtain spherical particles. These spherical particles were further annealed at 560 °C in nitrogen to obtain porous carbon nanotube interpenetrated Fe 3 o 4 Negative active material. attached Figure 4 The scanning electron microscope photos of these negative electrode active materials show that these negative electrode active materials are in the form of spherical particles interspersed with carbon nanotu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com