Carbon-based field effect transistor and preparation method thereof

A technology of transistor and carbon base field, which is applied in the field of nanoelectronics, can solve the problems of reducing carrier mobility and device performance degradation, and achieves the effects of good reliability and repeatability, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

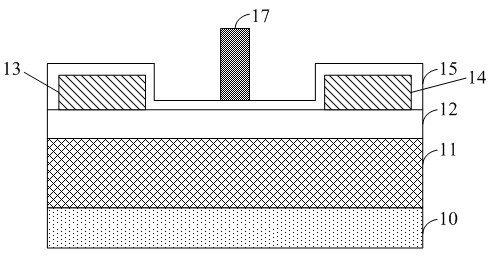

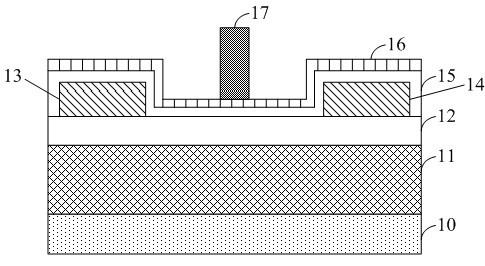

[0039] Embodiment 1: a graphene field effect transistor with metal titanium / gold as source-drain electrodes, benzocyclobutene organic dielectric layer and ALD hafnium oxide as gate composite dielectric layer, and metal nickel / gold as gate electrode.

[0040] Concrete preparation steps are as follows:

[0041] (1) On the graphene material on the 100nm silicon dioxide / bulk silicon substrate sheet, after forming the source-drain electrode shape by electron beam lithography, electron beam evaporates a layer of 10nm / 50nm thick titanium / gold (Ti / Au= 10 / 50nm) metal as the source-drain electrode, and then put the sample into acetone to peel off, remove the unnecessary metal layer, and obtain the source-drain metal electrode;

[0042] (2) Put the semiconductor substrate formed with an insulating layer, a conductive channel, a source electrode and a drain electrode into an oven filled with nitrogen, and keep the temperature of the oven at 120°C, and simultaneously coat the hexamethyldis...

Embodiment 2

[0048] Embodiment 2: a graphene field effect transistor with metal titanium / gold as source and drain electrodes, benzocyclobutene organic dielectric layer and atomic layer deposition hafnium oxide as gate composite dielectric layer, and metal nickel / gold as gate electrode.

[0049] The specific steps are similar to those in Example 1, but the temperature of the oven in step 2 is maintained at 110°C. In step 4, the BCB is treated by rapid thermal annealing (RTA). The BCB is subjected to rapid thermal annealing at 290°C for 15 seconds to form an organic dielectric layer with a thickness of 5nm.

Embodiment 3

[0050] Embodiment 3: a graphene field effect transistor with metal titanium / gold as the source and drain electrodes, benzocyclobutene organic dielectric layer and atomic layer deposition hafnium oxide as the gate compound dielectric layer, and metal nickel / gold as the gate electrode.

[0051] The specific steps are similar to those in Example 1, but in Step 3, BCB (Cyclotene 3022-46, purchased from Dow Chemical Company, USA) and decane were diluted at a volume ratio of 1:27. After step 4, measure the thickness of the BCB organic layer to be 50nm, and the thickness of the hafnium oxide layer to be 30nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com