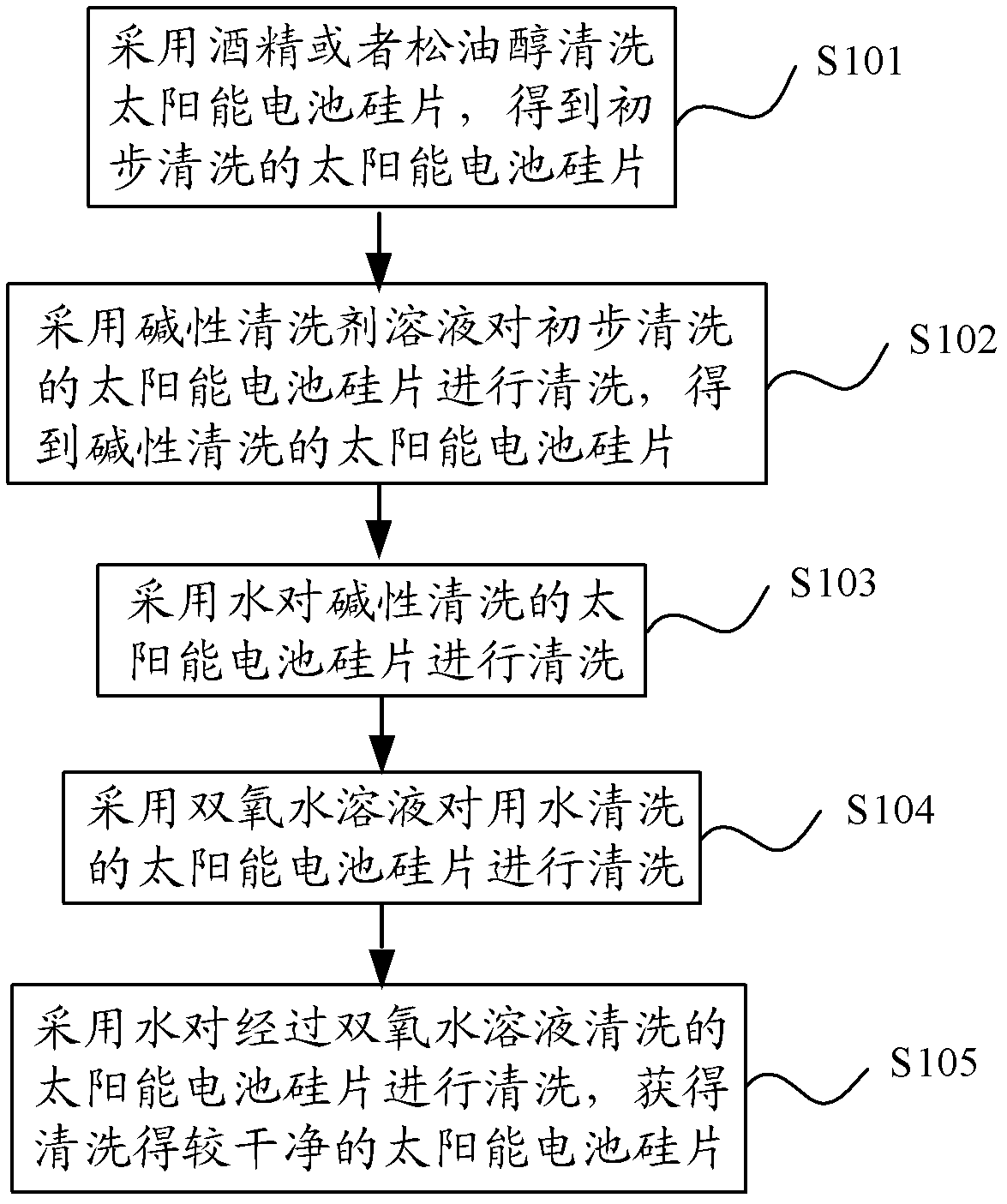

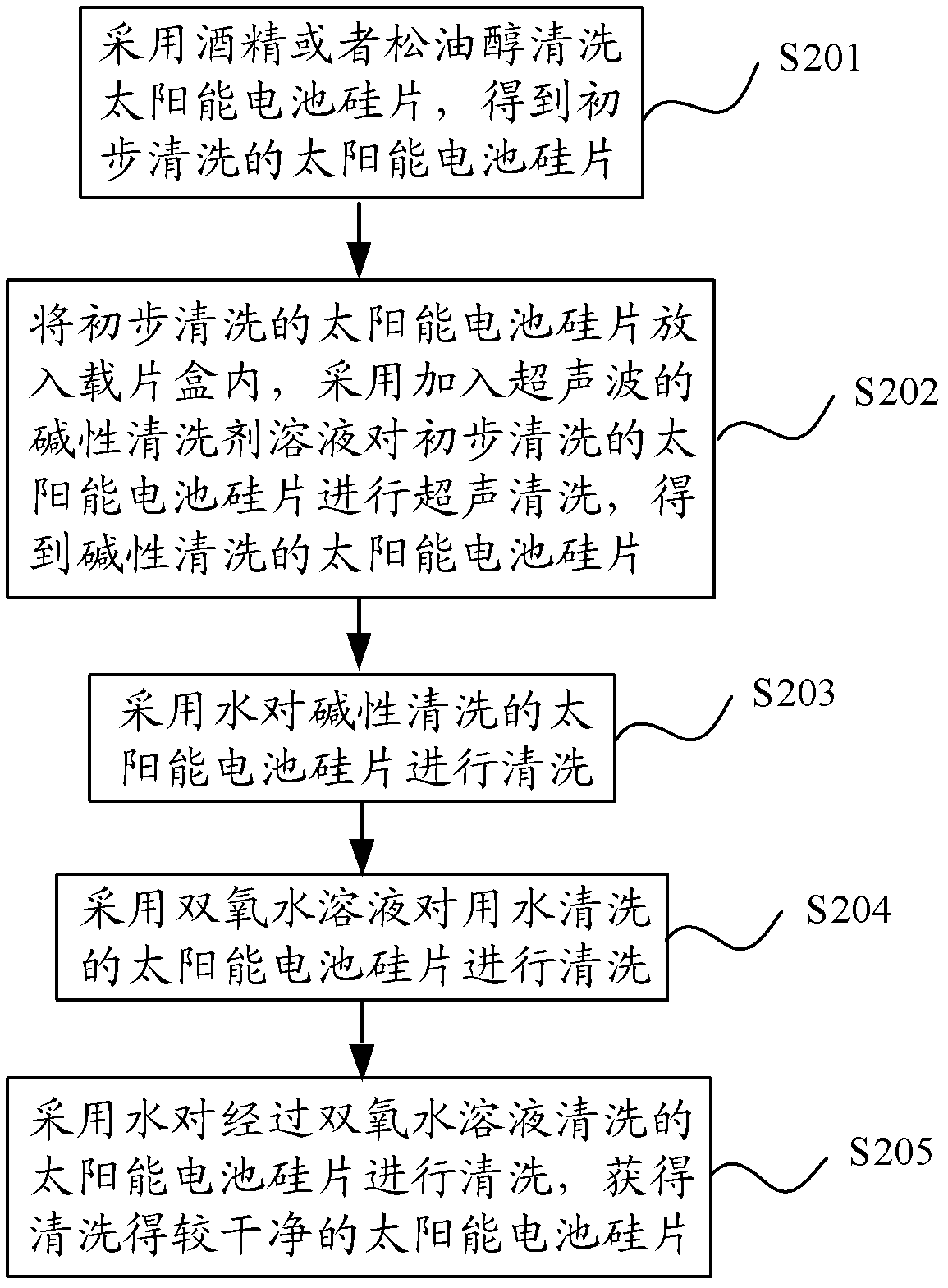

Cleaning method of solar battery silicon chip

A technology for solar cells and silicon wafers, applied in circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problems of unqualified silicon wafers, low silicon wafer reuse rate, affecting the qualified rate of finished products, etc., and reduce metal powder. and organic solvents, the effect of improving the reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] For the sake of reference and clarity, the technical terms involved in this patent are now explained as follows:

[0029] Alkaline cleaning agent: A commonly used cleaning agent mainly includes caustic alkali, phosphate, silicate, carbonate, chelating agent and surfactant.

[0030] Ultrasonic cleaning: a cleaning method that uses ultrasonic waves to act on the cleaning solution to more effectively remove oil and other impurities on the surface of the workpiece.

[0031] The invention provides a cleaning method for solar battery silicon wafers, which reduces metal powder and organic solvent remaining on the surface of solar battery silicon wafers, and further improves the reutilization rate of solar battery silicon wafers with unqualified printing paste.

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com