Combined wheel plate type evaporator condenser

A technology for evaporators and condensers, applied in evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problems of water treatment systems that are difficult to obtain high system efficiency, consume large pump power, and waste pump power, etc., to achieve Conducive to condensation, increase the saturation temperature, and enhance the effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with the accompanying drawings.

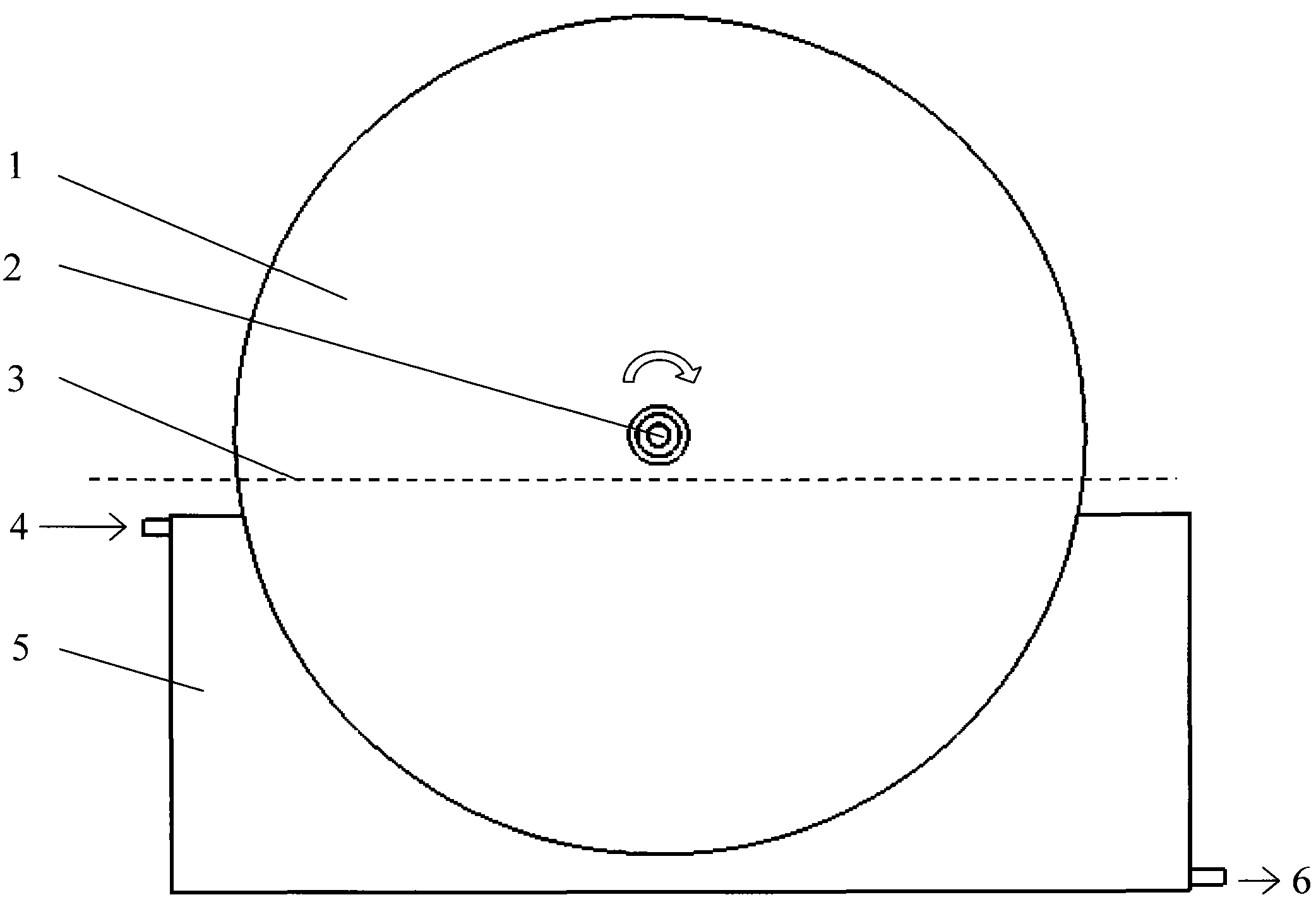

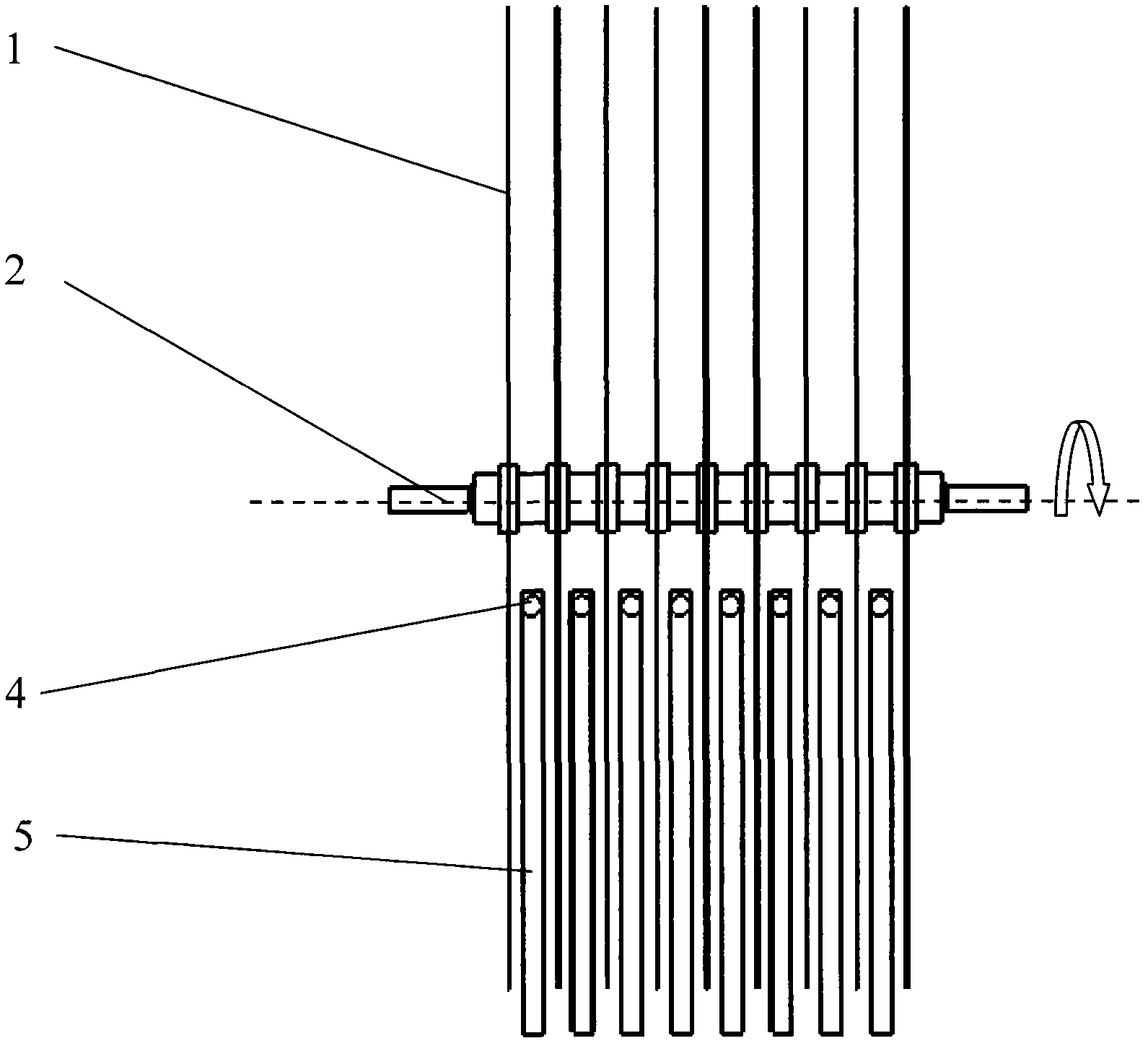

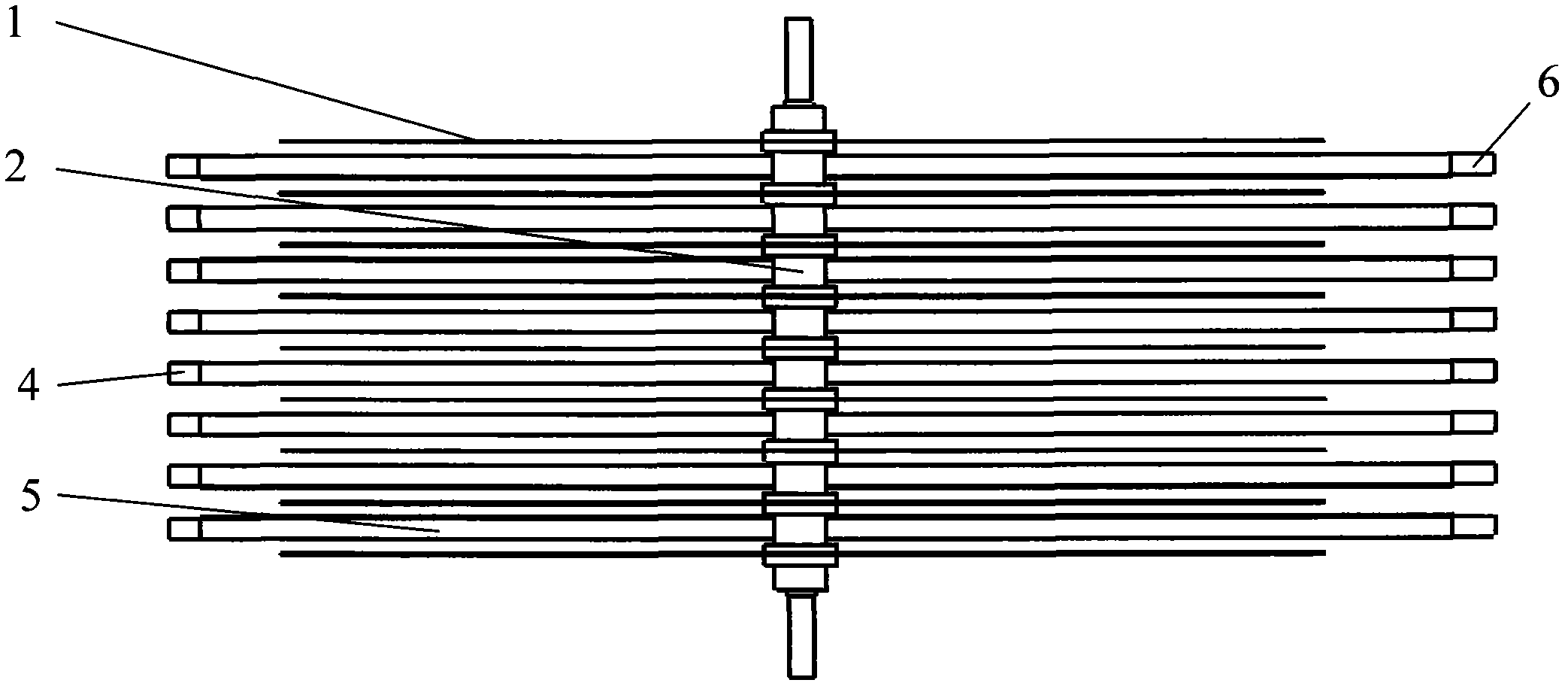

[0011] For the evaporator, the disk surface of the rotary disk evaporator (1) is made of corrosion-resistant materials (such as stainless steel and titanium alloy steel, etc.), and the disk surface carries the liquid in the liquid pool by rotation to the space above the liquid surface (3). Evaporation, control the speed and the water absorption and evaporation area of the evaporation surface, do not let the liquid splashed on the surface of the disk, try to make the liquid on the surface of the disk evaporate completely, even if there is liquid that has not evaporated, it will follow the turntable and melt into the pool again, so that The potential energy lost due to splashing of droplets in the spray evaporator is avoided. The condensed steam enters the plate condenser (5) from the inlet (4), condenses into water inside, and at the same time transfers the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com