Aluminum-free anti-counterfeiting lining paper for cigarettes and production method thereof

A production method and lining paper technology, applied in chemical instruments and methods, paper/cardboard layered products, paper, etc., can solve problems such as secondary pollution of aluminum foil paper, achieve good gas barrier performance, good adaptability, energy The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The aluminum-free anti-counterfeit inner lining paper for cigarettes of this embodiment is coated with paint on both sides of the anti-counterfeit paper with watermark anti-counterfeit feature or security thread anti-counterfeit feature to form a paint layer, and the thickness of the paint layer is 0.008mm. After coating water-soluble paint, it is made by printing colors or text patterns. It is composed of anti-counterfeiting paper base paper layer, paint layer and water-based printing oil layer (four layers). Each layer plays a different role and comprehensively meets anti-counterfeiting and packaging requirements.

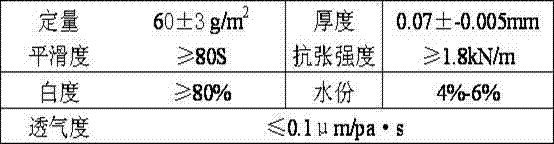

[0032] The quality index and performance of aluminum-free anti-counterfeiting cigarette lining paper are shown in the table below

[0033]

Embodiment 2

[0034] Example 2 Example of the production method of the aluminum-free anti-counterfeit cigarette lining paper:

[0035] A, prepare coating;

[0036] 1. Coating formula embodiment:

[0037] Embodiment 1 in parts by weight: 80 parts of papermaking china clay, 25 parts of polyvinyl alcohol, polyamide

[0038] 2 parts of amine polyurea resin (PAPU), 1 part of Z-16C coated paper coating dispersant.

[0039] Example 2: In parts by weight: 60 parts of papermaking china clay, 18 parts of polyvinyl alcohol, 5 parts of polyamide polyurea resin (PAPU), 0.3 part of Z-16C coating dispersant for coated paper.

Embodiment 3

[0040] Example 3: In parts by weight: 55 parts of papermaking china clay, 15 parts of polyvinyl alcohol, 6 parts of polyamide polyurea resin (PAPU), 0.5 part of Z-16C coating dispersant for coated paper.

[0041] 2. Examples of preparation methods of coatings (by weight):

[0042] Example 1

[0043] ① According to the coating formula, weigh 80 parts of papermaking clay, 25 parts of polyvinyl alcohol, 2 parts of polyamide polyurea resin (PAPU) water-repellent agent, and 1 part of Z-16C type coated paper coating dispersant;

[0044] ②. Pour 25 parts of polyvinyl alcohol into the gelatinization tank and add water at a concentration of 5%, that is, 5 parts of polyvinyl alcohol plus 95 parts of water (5 kg of polyvinyl alcohol plus 95 kg of water), heat and stir until it dissolves, making into polyvinyl alcohol emulsion.

[0045] ③. Add 80 parts of papermaking china clay, 200 parts of 5% polyvinyl alcohol emulsion, 2 parts of polyamide polyurea resin (PAPU) water repellent an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com