Profiled fire-retardant bright terylene FDY (Fully Drawn Yarn) filament and production process thereof

A production process, light polyester technology, applied in the manufacture of fire-resistant and flame-retardant filaments, filament/thread molding, melting of filament raw materials, etc., can solve problems such as stuffy feeling when wearing, poor melting resistance, poor hygroscopicity, etc., to achieve Good moisture absorption function, easy cooling, and less broken ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

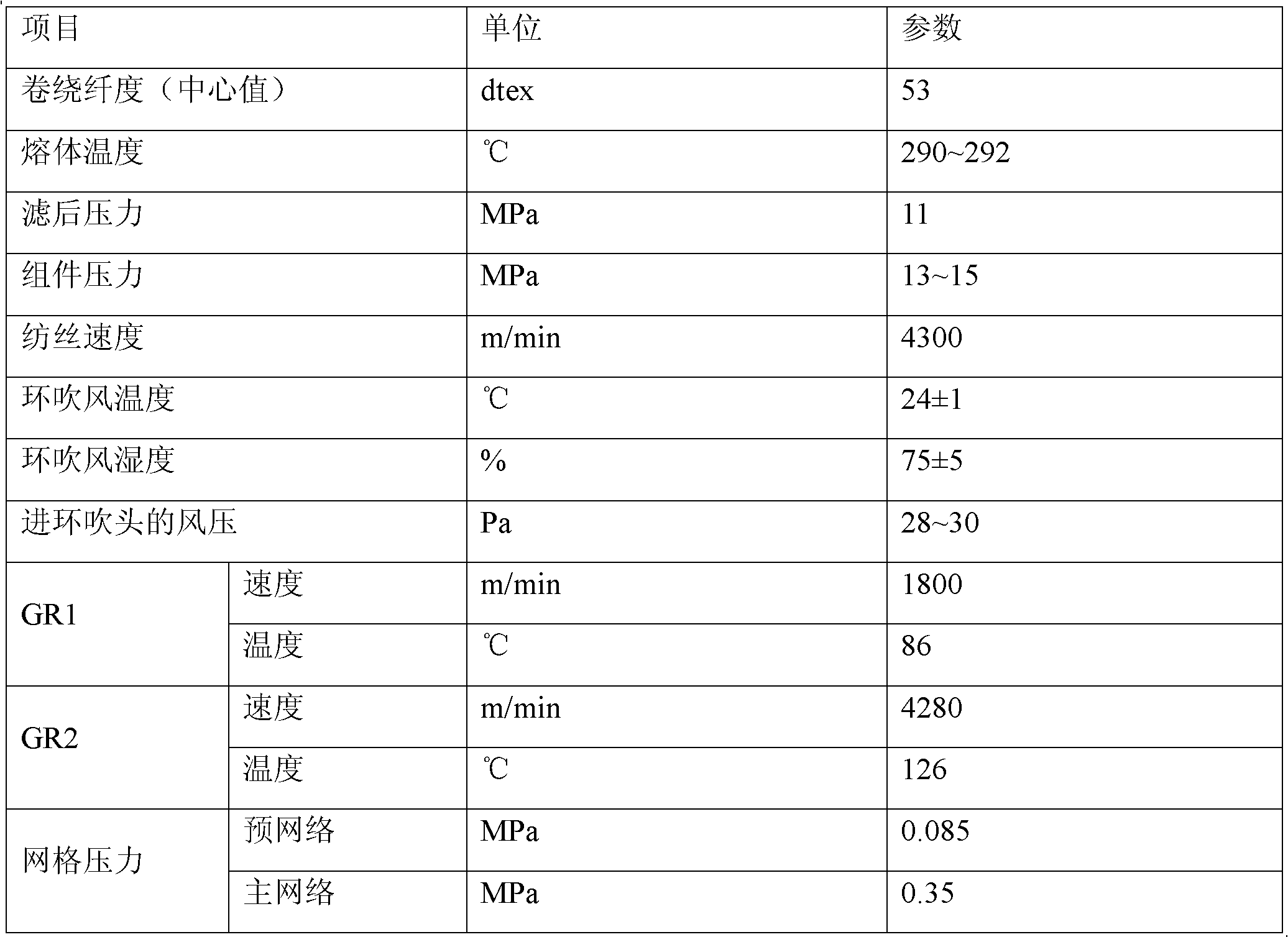

[0023] Example 1 Preparation of 53dtex / 48f trilobal shaped flame retardant

[0024] Production equipment and instruments: Zhengzhou Zhongyuan BM type drying tower; German Barmag spinning, stretching and winding machines; YG086 yarn length measuring machine (Changzhou Second Textile Instrument Factory); YG021 single yarn strength machine (Changzhou Second Textile Instrument Factory).

[0025] By weight, weigh 93% of the bright PET chips (intrinsic viscosity 0.648dl / g, melting point 260 ° C, Sinopec Yizheng Chemical Fiber Co., Ltd.) into the wet chip silo, pre-crystallization at 170 ° C, 172 ° C dry under conditions; weigh 7% of the flame retardant masterbatch (SF-FR, Shandong Tengzhou Textile Auxiliary Factory) and dry at 125°C; pre-crystallized and dried bright PET slices and dried flame retardant masterbatch After the pellets are mixed, the PET melt is made by a screw extruder; the temperature of each zone of the screw is: 275°C in the first zone, 280°C in the second zone, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com