Low-frequency high-damping rubber-based piezoelectric composite material and preparation method thereof

A piezoelectric composite material and rubber-based technology, applied in the field of damping materials, can solve the problems of high volume fraction of piezoelectric ceramic powder, high material hardness, limited application range, etc., and achieve the effect of improving the damping factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

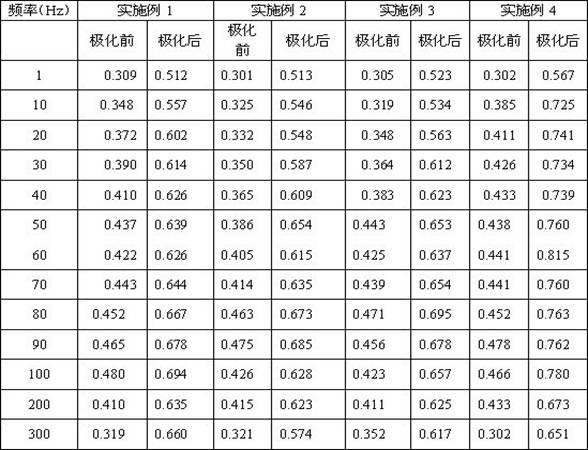

[0024] Using non-diene rubber as matrix material, PZT piezoelectric ceramic powder, conductive carbon black and coupling agent were added to prepare rubber-based piezoelectric damping composite material. Weigh the mixed powder of rubber base material, piezoelectric ceramic powder, conductive carbon black and titanate coupling agent according to the formula ratio in Table 1, knead on the internal mixer, and after mixing evenly, take out the sheet, cut it, and put it into the Mold, formed on a thermoforming machine. The molding temperature (upper and lower molds) is 160°C, the molding pressure is 5MPa, and the molding time is 50min. The molded piezoelectric damping composite material was polarized in a high-voltage DC oil bath polarization device with a polarization voltage of 4000V, a polarization temperature of 80°C, and a polarization time of 15 minutes.

[0025]

[0026] Table 1 Example 1-4 formula (mass parts)

[0027] Raw material name Example 1 Example 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com