Method for preparing polyethylene/graphene conductive composite material

A technology of conductive composite materials and graphene, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of increased percolation threshold and poor dispersion effect of composite materials, achieve high conductivity and reduce agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 The preparation process condition of preferred polyethylene / graphene conductive composite material

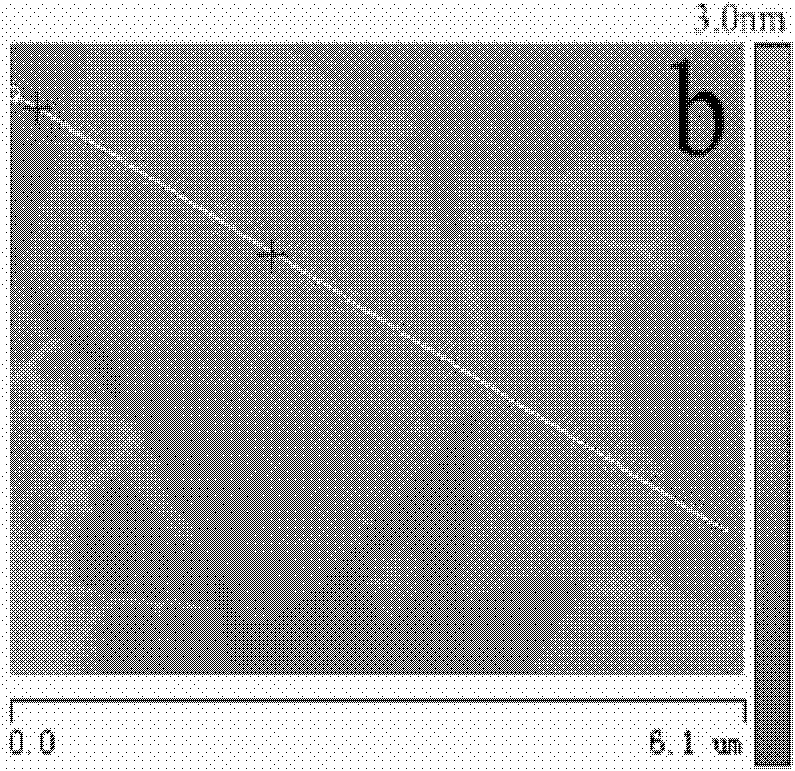

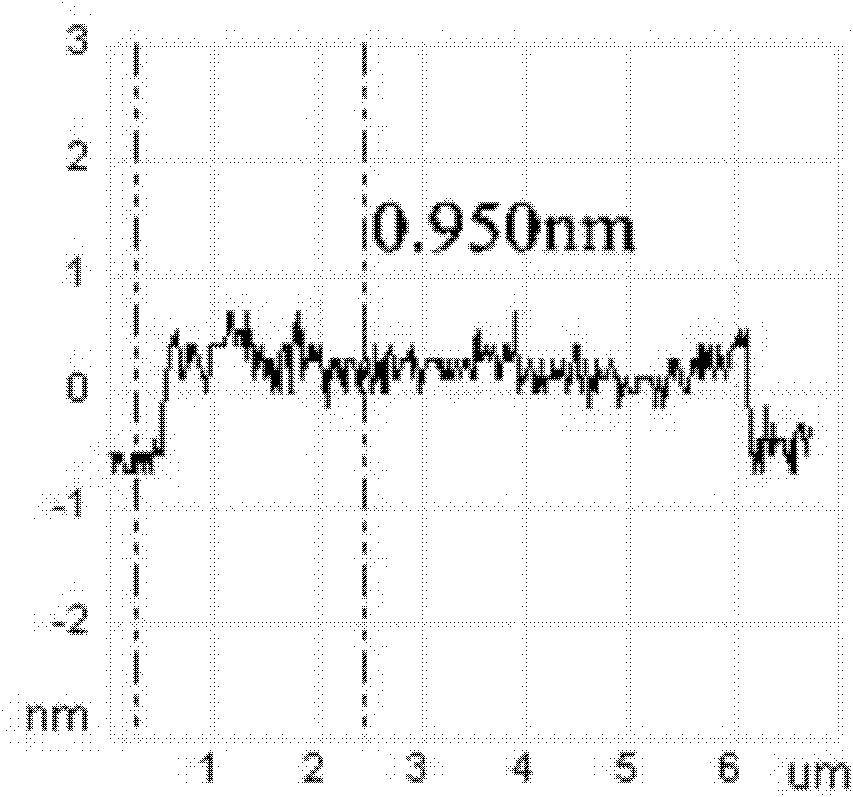

[0034] Using ultra-high molecular weight polyethylene powder with a molecular weight of 3 million as raw material, the preparation of polyethylene / graphene conductive composite material can be divided into two steps, the first step is the preparation of polyethylene powder coated with graphene oxide, and the second step is to polymerize The graphene oxide on the surface of the ethylene particles is reduced to graphene.

[0035] In the first step, 85mg of graphene oxide is placed in 400mL of water and ethanol in a solvent with a mass ratio of 50:1, and after being dispersed in an ultrasonic cleaner for 2 hours, 20g of ultra-high molecular weight polyethylene powder is added to the solution , with mechanical stirring at 95°C, when a large amount of solvent evaporated, dry in an oven at 80°C for 24 hours, and then continue drying in a vacuum oven at 95°C for 24...

Embodiment 2

[0041] Embodiment 2 The scope of application of the ratio of raw materials for preparing polyethylene / graphene conductive composite material

[0042] The graphene oxide raw material consumption in embodiment 1 is replaced by 10mg, 21.6mg, 46.6mg, 163.3mg, 238.3mg or 318.3mg, the steps and conditions of preparing polyethylene / graphene conductive composite material are the same as embodiment 1, all Can implement the present invention, prepare the flaky polyethylene / graphene conductive composite material that graphene content is respectively 0.01vol%, 0.028vol%, 0.06vol%, 0.2vol%, 0.3vol%, 0.4vol%; The electrical conductivity of ethylene / graphene conductive composites in units of s / cm is 1.6×10 -7 , 2×10 -4 , 0.0031, 0.018, 0.038, 0.045.

[0043] The implementation effect can be found in Figure 4 and Figure 9 .

Embodiment 3

[0044] Example 3 The scope of application of the process conditions for preparing polyethylene / graphene conductive composites

[0045] The steps for preparing the polyethylene / graphene conductive composite material are the same as in Example 1. In the first step in Example 1, the dispersion in the ultrasonic cleaner was replaced for 3 hours, and the polyethylene powder was added and mechanically stirred at 90 ° C. It was also possible to obtain a polymer powder coated with a layer of graphene oxide. Composite particles with a shell-core structure.

[0046] Alternatively, the steps for preparing the polyethylene / graphene conductive composite material are the same as in Example 1. In the second step in Example 1, the mass ratio of hydrazine hydrate and the composite particles of the core-shell structure is 8: 10, heated to 90 ° C and carried out mechanical stirring for 6 hours, the graphene oxide on the polymer can also be reduced into graphene, produced

[0047] That is, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com