Chitosan/polylysine in-situ gel and preparation method thereof

A technology of polylysine and in situ gel is applied in the field of biomedical materials to achieve the effects of controllable reaction, simple preparation process and increased histocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

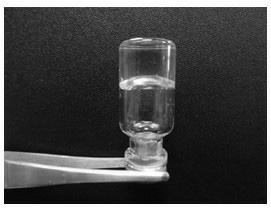

Image

Examples

Embodiment 1

[0022] Weigh 14mg of succinimide sulfate, dissolve in 8ml of PBS with pH=7.2~7.4, stir until a clear solution is formed; weigh 30mg of e -Polylysine, completely dissolved in 2ml of PBS with pH=7.2~7.4, stirred until a clear solution was formed; at room temperature, the above polylysine solution was added to the succinimide sulfate solution, at a stirring rate of 50rpm Mix well, react for 0.5 hour, dialyze with deionized water at room temperature for 24 hours, and freeze-dry the dialyzed product to obtain maleimidated polylysine with a double bond molar substitution degree of 5%. Dissolving the maleimidated polylysine powder in PBS with a pH value of 7.2 to 7.4 to prepare a maleimidated polylysine solution with a concentration of 40 mg / ml;

[0023] Weigh 1g chitosan ( =1 zero.5×10 5 , the degree of deacetylation is 92%) was dissolved in 90ml of deionized water to form a suspension, 0.8g of 1-hydroxybenzotriazole was added to the above suspension, stirred to obtain a clear so...

Embodiment 2

[0026] Weigh 30mg of succinimide sulfate, dissolve in 16ml of PBS with pH=7.2~7.4, stir until a clear solution is formed; weigh 31mg of e-Polylysine, completely dissolved in 4ml of PBS with pH=7.2~7.4, stirred until a clear solution was formed; at room temperature, the above polylysine solution was added to the succinimide sulfate solution, at a stirring rate of 100rpm Mix well, react for 2 hours, dialyze with deionized water at room temperature for 24 hours, and freeze-dry the dialyzed product to obtain maleimidated polylysine with a double bond molar substitution of 30%. Dissolving the maleimidated polylysine powder in PBS with a pH value of 7.2 to 7.4 to prepare a maleimidated polylysine solution with a concentration of 40 mg / ml;

[0027] Thiolated chitosan with a degree of mercapto substitution of 150 μmol / g ( =1.5×10 5 , deacetylation degree is 92%) chitosan is dissolved in phosphate buffer saline (PBS) with a pH value of 7.2~7.4 to prepare a thiolated chitosan solutio...

Embodiment 3

[0030] Weigh 20mg of succinimide sulfate, dissolve in 11ml of PBS with pH=7.2~7.4, stir until a clear solution is formed; weigh 30mg of e -Polylysine, completely dissolved in 3ml of PBS with pH=7.2~7.4, stirred until a clear solution was formed; at room temperature, the above-mentioned polylysine solution was added to the succinimide sulfate solution, at a stirring rate of 80rpm Mix well, react for 1 hour, dialyze with deionized water at room temperature for 24 hours, and freeze-dry the dialyzed product to obtain maleimidated polylysine with a double bond molar substitution degree of 15%. Dissolving the maleimidated polylysine powder in PBS with a pH value of 7.2 to 7.4 to prepare a maleimidated polylysine solution with a concentration of 40 mg / ml;

[0031] Thiolated chitosan with a degree of mercapto substitution of 160 μmol / g ( =1.2×10 5 , deacetylation degree is 85%) chitosan is dissolved in phosphate buffer saline (PBS) with a pH value of 7.2~7.4 to prepare a thiolated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com