Gelatin embolism microsphere and preparation method and application thereof

A gelatin embolization microsphere and gelatin embolization technology, applied in the field of interventional medicine, can solve problems such as difficult grading and labeling of particle size, microspheres with poor elasticity, catheter blockage, etc., and achieve accurate sieving and grading and labeling particle size, suitable Large-scale industrial production, the effect of preventing catheter clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: Preparation of gelatin microspheres

[0035] (1) preparation concentration is the gelatin aqueous solution of 21.6% g / ml;

[0036] (2) Add the aqueous gelatin solution prepared in step (1) to liquid paraffin containing 1% g / ml Span 80 at 50°C, stir for 10 minutes, then drop the temperature to 2-5°C, stir for 30 minutes, and the stirring speed Be 300rpm, leave standstill, make the microsphere that forms settle;

[0037] (3) pouring over to remove the oil phase, and repeatedly washing the oil phase remaining on the surface of the microspheres with acetone, and filtering out the microspheres;

[0038] (4) Add the microspheres obtained in step (3) to formaldehyde solution with a pH of 8 to 9 and a concentration of 8% g / ml and stir for 5 minutes, react at 4°C for 13 hours, wash the microspheres with distilled water, and freeze-dry save.

[0039] Determination of microsphere properties

[0040] a. Morphological observation

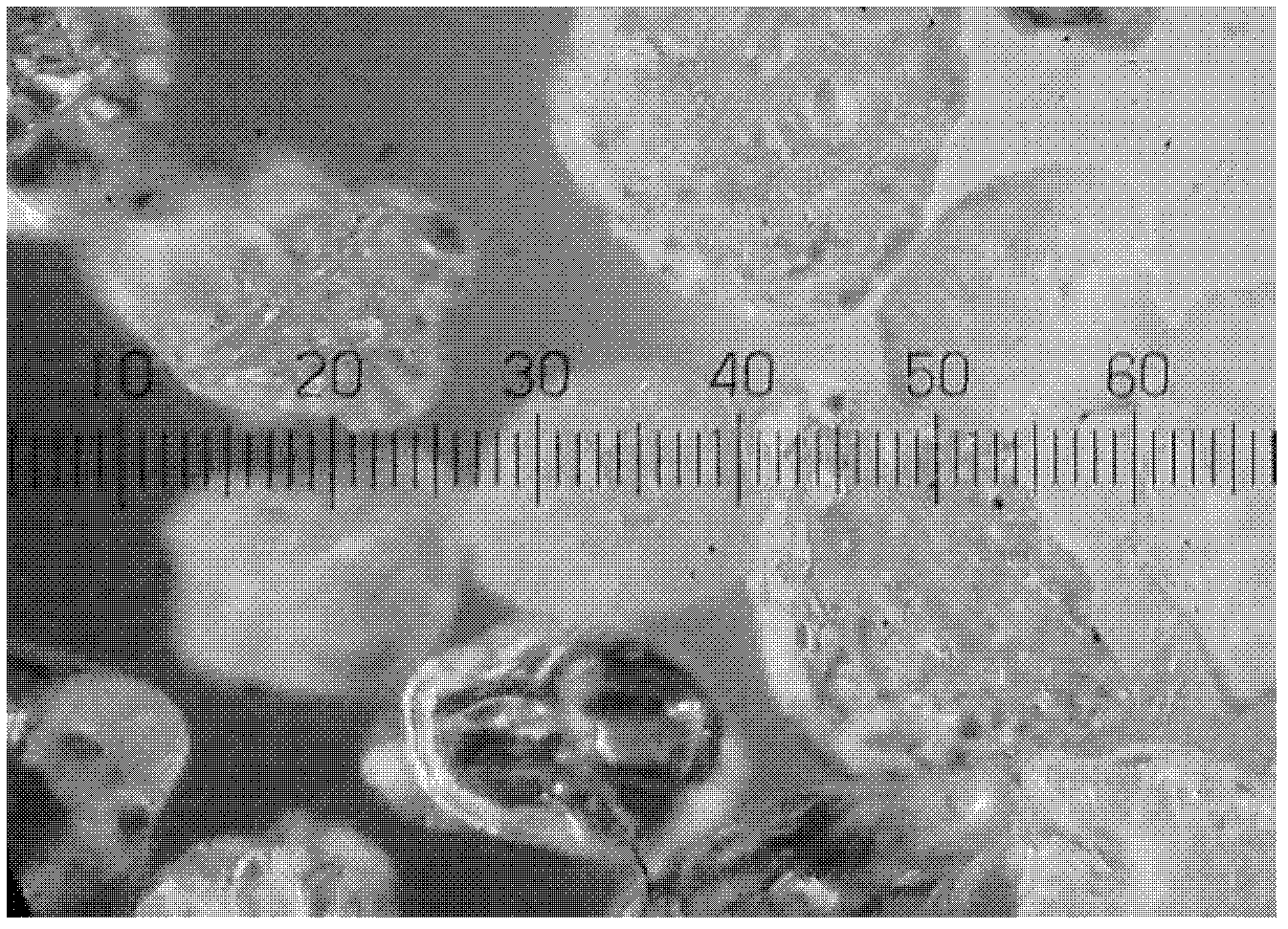

[0041] The microspheres were soa...

Embodiment 2

[0050] Embodiment 2: Preparation of gelatin microspheres

[0051] (1) preparation concentration is the gelatin aqueous solution of 40% g / ml;

[0052] (2) Add the aqueous gelatin solution prepared in step (1) to liquid paraffin containing 2% g / ml Span 80 at 50°C, stir for 10 minutes, then drop the temperature to 2-5°C, stir for 30 minutes, and the stirring speed Be 350rpm, leave standstill, the microsphere that makes formation settles;

[0053] (3) pouring over to remove the oil phase, and repeatedly washing the oil phase remaining on the surface of the microspheres with acetone, and filtering out the microspheres;

[0054] (4) Add the microspheres that step (3) obtains to pH 8~9, concentration is the glutaraldehyde aqueous solution of 41.6% g / ml and stir for 5 minutes, after reacting for 40 hours at 4 DEG C, wash the microspheres with distilled water, Freeze-dried and stored.

[0055] Observe the morphology of the microspheres in the same manner as in Example 1. The microsp...

Embodiment 3

[0059] Embodiment 3: Preparation of gelatin microspheres

[0060] (1) Take gelatin and prepare an aqueous gelatin solution with a concentration of 30% g / ml;

[0061] (2) Add the aqueous gelatin solution prepared in step (1) to liquid paraffin containing 0.8% g / ml Span 80 at 50°C, stir for 10 minutes, then drop the temperature to 2-5°C, stir for 30 minutes, and the stirring speed Be 300rpm, leave standstill, make the microsphere that forms settle;

[0062] (3) pouring over to remove the oil phase, and repeatedly washing the oil phase remaining on the surface of the microspheres with acetone, and filtering out the microspheres;

[0063] (4) Add the microspheres obtained in step (3) to pH 8-9 and formaldehyde solution with a concentration of 1.3% g / ml and stir for 5 minutes, react at 4°C for 13 hours, wash the microspheres with distilled water, and freeze-dry save.

[0064] Observe the morphology of the microspheres in the same manner as in Example 1. The microspheres in this ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com