Preparation method of nanoscale solidago canadensis L. microcrystalline cellulose

A microcrystalline cellulose, nano-level technology, applied in fiber raw material processing, textiles and papermaking, etc., can solve the problems of lack of resources, high cost, single product, etc., and achieve the effect of solving ecological and environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

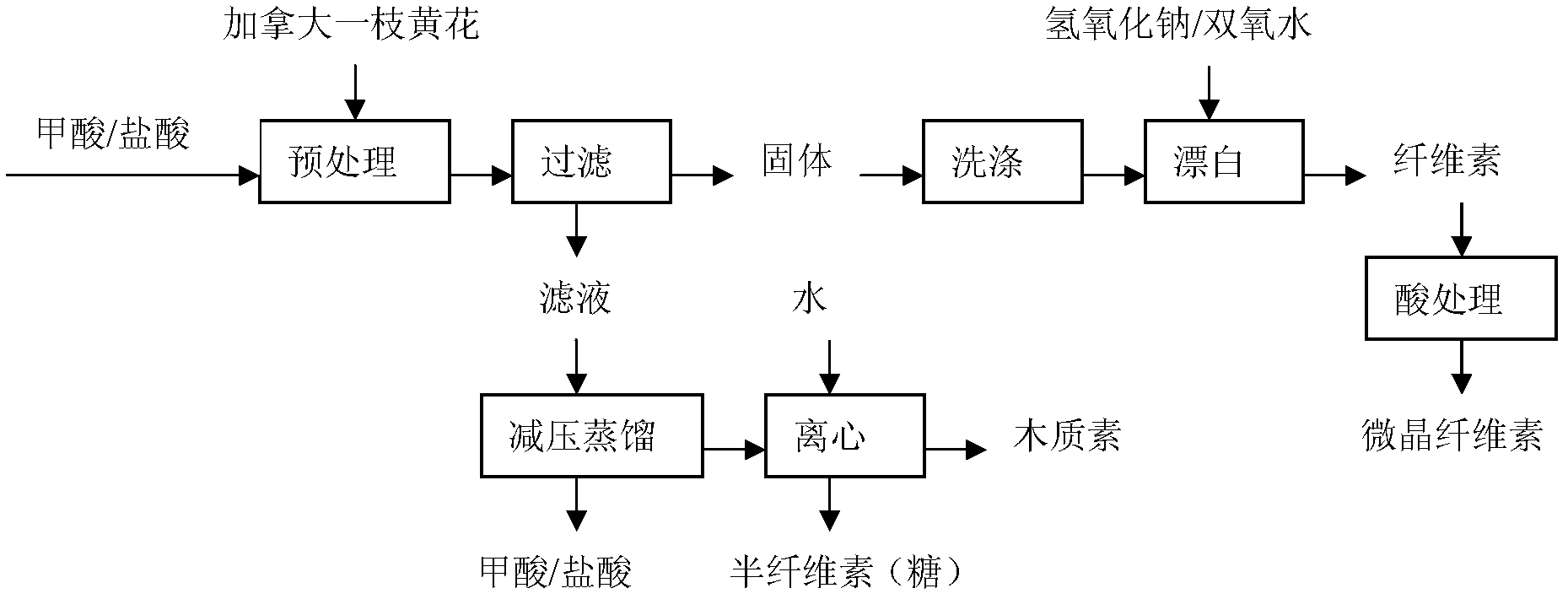

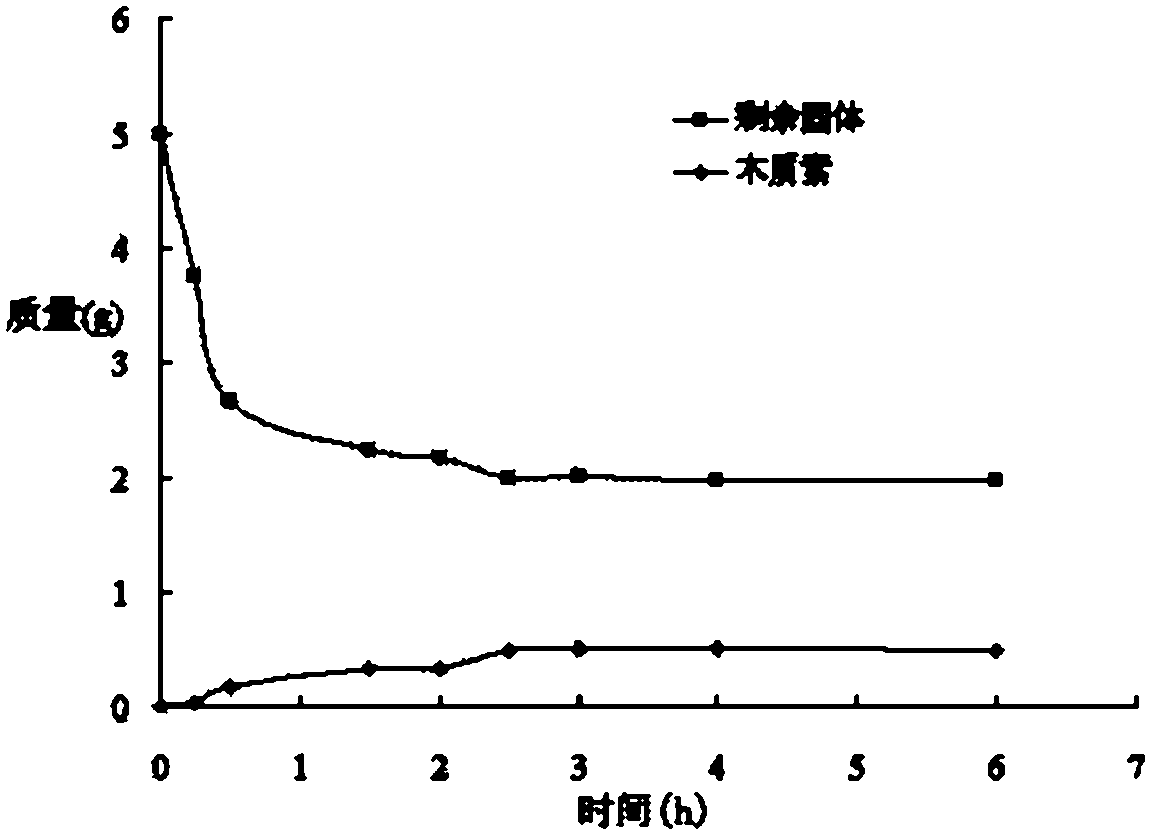

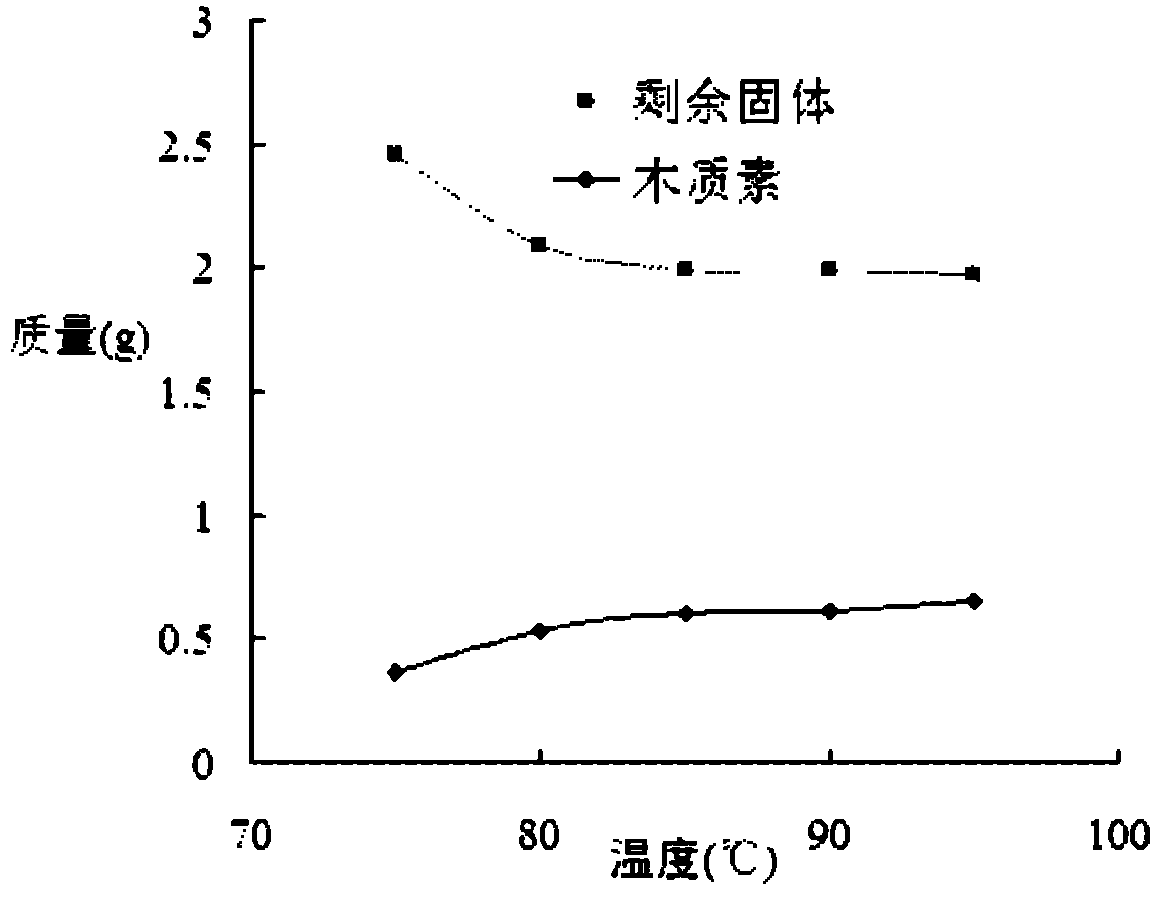

[0026] (1) Weigh 5g of Solidago canadensis stalks in a 250ml Erlenmeyer flask, add 60mL of 88% formic acid and 1.5mL of 37% hydrochloric acid, place in a magnetic stirring heater, and continuously stir through a magnetic rotor at a speed of 400r / min, react at 85°C for 15min, 30min, 1.5h, 2h, 2.5h, 3h, 4h, 6h, and react at 75, 80, 85, 90, 95°C for 2.5h;

[0027] (2) The reaction slurry is taken out for suction filtration, and the obtained solid is washed with about 40 mL of 88% formic acid and then suction filtered, and the collected filtrate is subjected to vacuum distillation to recover a mixed solution of formic acid and hydrochloric acid (reusable);

[0028] (3) adding water to the solution after vacuum distillation to dissolve the hydrolyzed sugar of hemicellulose, water-insoluble lignin is recovered by a centrifuge, quantified after drying, and the remaining solid obtained by suction filtration is washed to neutral with distilled water, and quantified after drying;

[00...

Embodiment 2

[0035] (1) After crushing 6g of solidago canadensis stalks, put them in a reaction vessel, add 60mL of formic acid with a mass fraction of 88% and 1.5mL of hydrochloric acid with a mass fraction of 36-38%, stir, and react at 85°C for 2.5 h; then suction filtered to obtain a solid;

[0036] (2) Add a sodium hydroxide solution with a mass concentration of 17.5% to the above solid, so that the pH of the suspension is 11, then add a hydrogen peroxide solution, and react at 80° C. for 1 hour; The material was suction filtered, washed with distilled water until neutral, and the obtained solid was dried to obtain α-cellulose;

[0037] (3) Take 5 g of the above-mentioned α-cellulose in a reaction vessel, add 100 mL of hydrochloric acid with a mass concentration of 6%, stir and react at 100° C. for 60 min, filter with suction after cooling, and finally wash, dry and grind the obtained solid to obtain Microcrystalline Cellulose Products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com