Efficient polylactic acid nucleating agent, and preparation method and application thereof

A nucleating agent, polylactic acid technology, applied in the field of polylactic acid crystallization modification, can solve the problems of human body and environmental hazards, involvement, etc., achieve high safety, improve heat resistance, and significant nucleation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

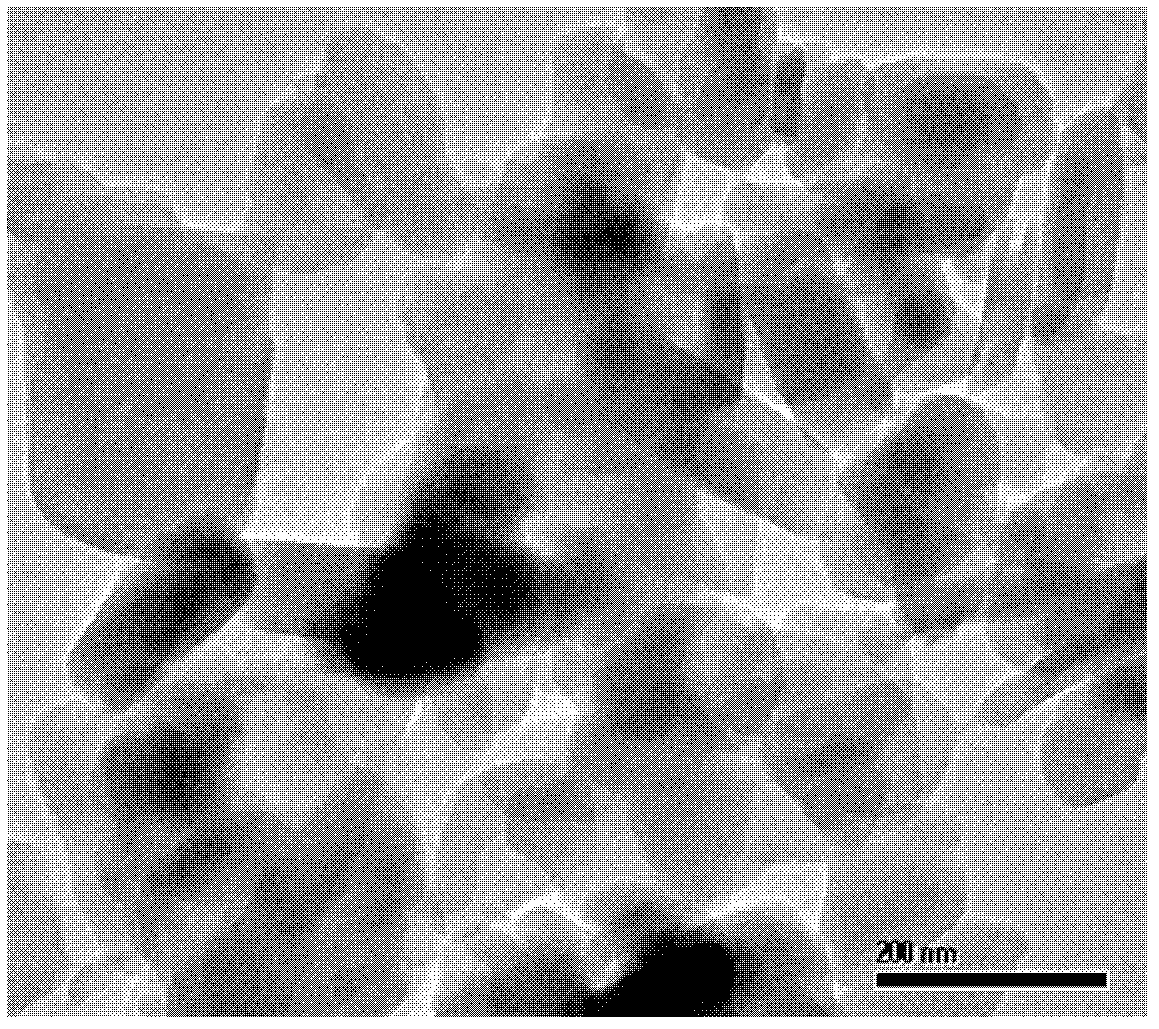

Image

Examples

Embodiment 1

[0023] Utilize zinc acetate to prepare the method for zinc citrate complex nucleating agent: 2.20g (0.01 mole) zinc acetate is dissolved in the mixed solution of 75 milliliters of ethanol and 3 milliliters of distilled water, stirred and refluxed 3 hours in 80 ℃ of water baths, then to Add 2.10g (0.01 mole) citric acid in the solution, continue reaction 3.5 hours, naturally cool to room temperature after reaction finishes, suction filtration, filter cake are washed 3 times with ethanol and water, obtain white powder after drying, fusing point (decomposition temperature) is 307°C.

[0024] The above-prepared nucleating agent and polylactic acid (with a number average molecular weight of 93,000) were dried in a vacuum oven at 70° C. for 10 hours. In terms of parts by mass, 99.8 parts of polylactic acid and 0.2 parts of nucleating agent were pre-mixed by a high-speed mixer, and then melt-kneaded and granulated with a SHJ-20 twin-screw extruder. The heating temperature of the fiv...

Embodiment 2

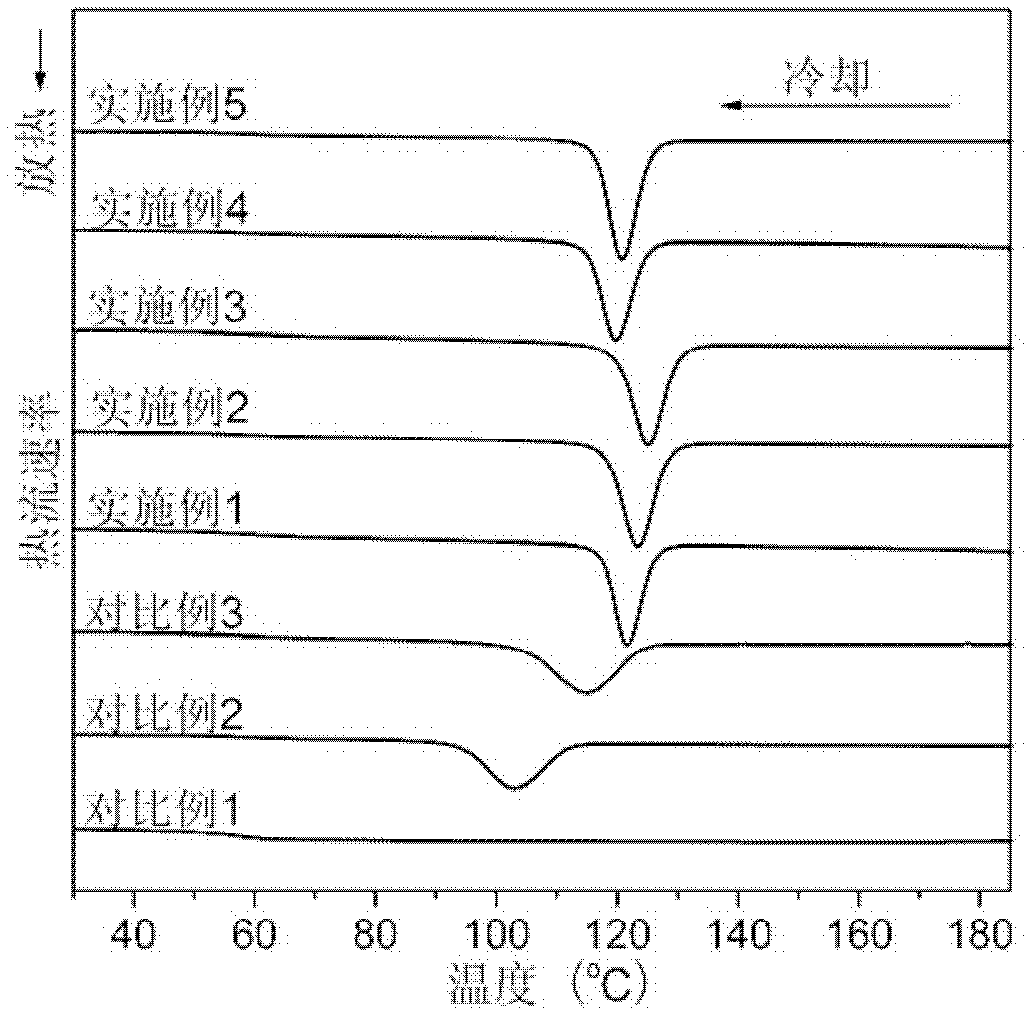

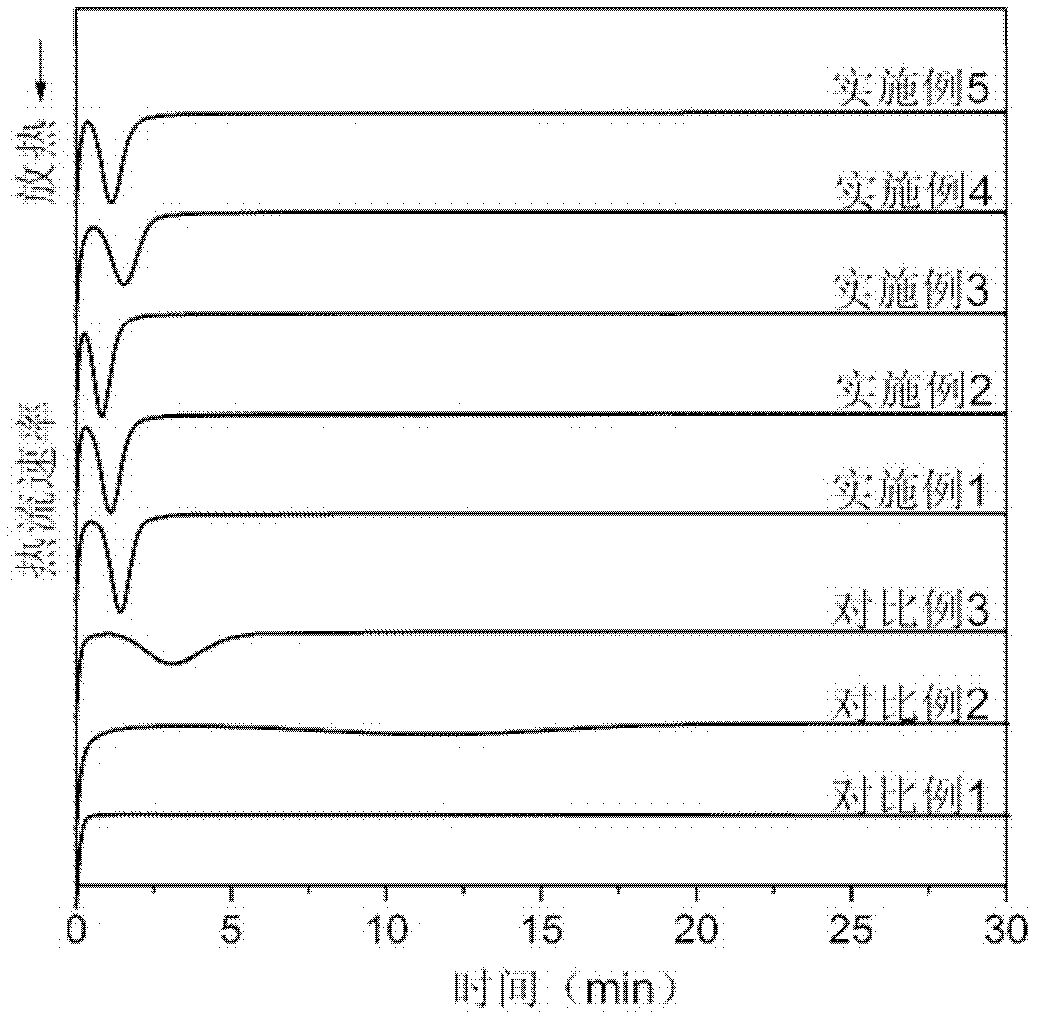

[0027] Weigh 99.5 parts of polylactic acid (the number average molecular weight is 93,000) and 0.5 part of the nucleating agent prepared in the above-mentioned Example 1, experience the same melt mixing and injection molding process in Example 1, and test the crystallization parameters and heat distortion temperature , see the result figure 1 , figure 2 and Table 1.

Embodiment 3

[0029] Weigh 99 parts of polylactic acid (the number average molecular weight is 93,000) and 1 part of the nucleating agent prepared in the above-mentioned Example 1, undergo the same melt mixing and injection molding process in Example 1, and test the crystallization parameters and heat distortion temperature , see the result figure 1 , figure 2 and Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com