High-concentration integrated chemical organic wastewater treatment process

A high-concentration technology for organic wastewater treatment, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as huge investment, achieve low operating costs, reduce consumption, The effect of improving biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

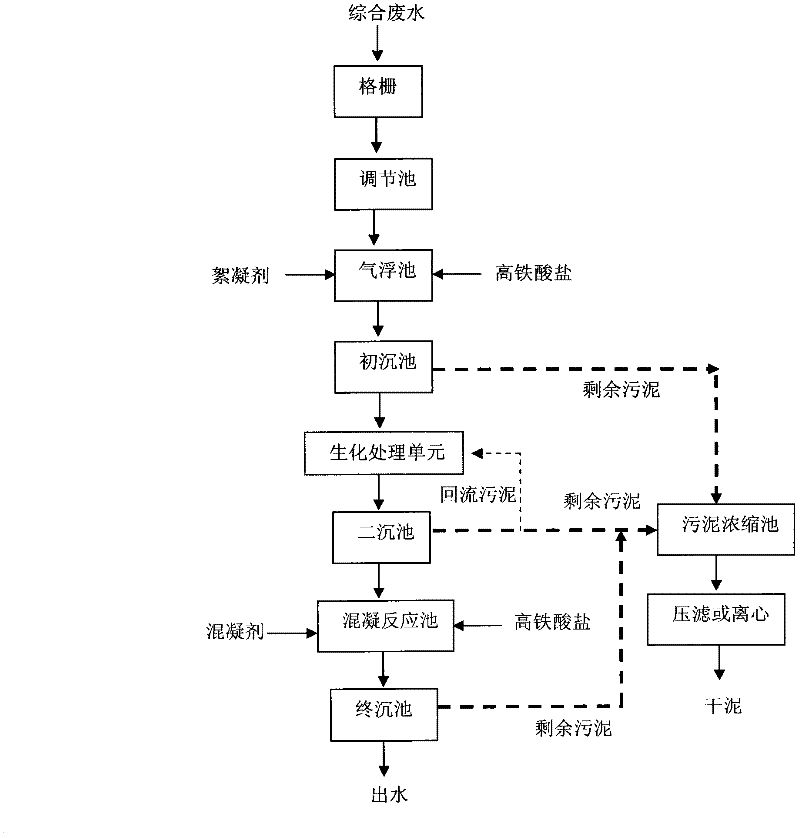

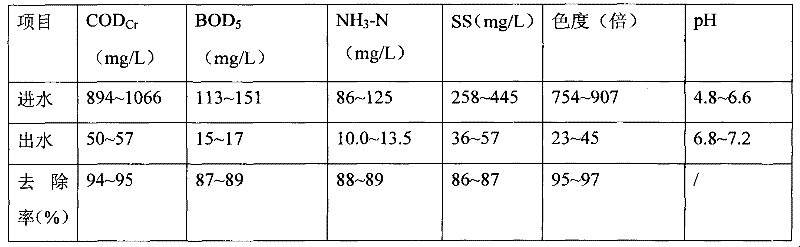

[0032] Example: This test uses figure 1 For the wastewater treatment process shown, comprehensive chemical wastewater from a sewage treatment plant in a chemical park in Ningbo was selected as the test object. The specific treatment process is as follows: the wastewater passes through the grid to remove part of the suspended matter and enters the adjustment tank, and then enters the air flotation tank. According to the wastewater quality, 50~150mg / L ferrate solid is added for oxidation pretreatment, and then 0.1% is added. Concentration of flocculant PAM, the slag and sludge produced by precipitation are transferred to the sludge thickening tank, the sewage enters the hydrolysis acidification tank for anaerobic biological treatment, and the sewage from the hydrolysis acidification tank enters the aerobic tank for good Oxygen biological treatment to further remove the organic matter in sewage. After aerobic treatment, the sewage is precipitated in the secondary sedimentation tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com