Preparation method of supercapacitor electrode material manganese dioxide

一种超级电容器、电极材料的技术,应用在电容器、电解电容器、氧化锰/氢氧化锰等方向,能够解决电极材料放电比电容量低、循环稳定性差等问题,达到解决大规模应用难、高比电容、良好电化学稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

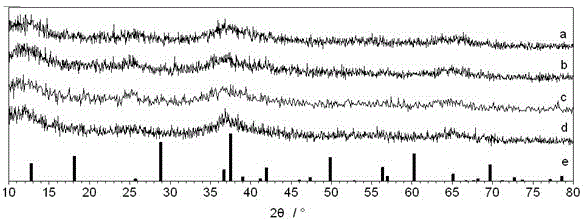

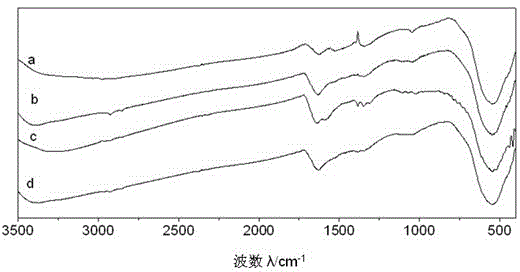

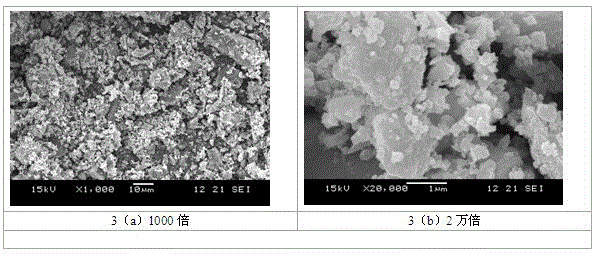

Image

Examples

Embodiment 1

[0035] (1) Take raw material pyrrole and potassium permanganate respectively, and the molar ratio of pyrrole and potassium permanganate is 1:0.6;

[0036] (2) Disperse and dissolve the taken pyrrole monomer into water, stir well to obtain solution A; the volume ratio of pyrrole to water is 1:25;

[0037] (3) dissolving the potassium permanganate in water to obtain solution B; the volume of solution B obtained is 3 times the volume of solution A;

[0038] (4) Slowly adding solution B to solution A, stirring and reacting for 8 hours at a temperature of 5 °C;

[0039] (5) Filtration of the reaction product to obtain a solid powdery precipitate, respectively washing the precipitate with deionized water and ethanol solvent until the filtrate is colorless;

[0040] (6) Vacuum dry the washed solid powder product at 60 °C for 18 h to obtain the electrode material MnO 2 Powder, can be used to prepare supercapacitor cathode material.

Embodiment 2

[0042] The ratio of pyrrole to water by volume is 1:30 to prepare solution A, and potassium permanganate is dissolved in water to prepare solution B, and the volume of the prepared solution B is 3 times the volume of solution A; The molar ratio of potassium permanganate in B is 1:0.7.

[0043] The solution B was slowly added to the solution A, and the reaction was stirred for 6 hours at a temperature of 2 °C;

[0044] The reaction solution was filtered to obtain a solid powder product, which was washed with deionized water and ethanol solvent respectively until the filtrate was colorless;

[0045] Dry the washed solid powder product at 70°C for 14 hours to obtain the electrode material MnO 2 Powder for the preparation of supercapacitor cathode materials.

Embodiment 3

[0047] The volume ratio of pyrrole and water is 1:35 to make A solution, and the volume of the obtained solution B is 2.5 times the volume of solution A; the molar ratio of pyrrole in solution A to potassium permanganate in solution B is 1:0.8 .

[0048] The solution B was slowly added to the solution A, and the reaction was stirred at a temperature of 1 °C for 12 hours;

[0049] The reaction solution was filtered to obtain a solid powder product, which was washed with deionized water and ethanol solvent respectively until the filtrate was colorless;

[0050] Dry the washed solid powder product at 80°C for 24 hours to obtain the electrode material MnO 2 Powder for the preparation of supercapacitor cathode materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com