Microparticle feed for sturgeon fry and processing method of same

A processing method and microparticle technology, applied in animal feed, animal feed, application, etc., can solve the problems of infection by germs, large randomness, and insufficient nutrition, etc., to improve digestion and absorption rate, reduce environmental pollution, and water stability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

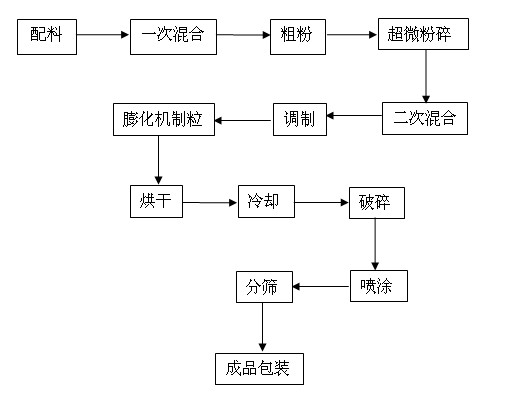

Method used

Image

Examples

Embodiment 1

[0033] 1. Feed formula

[0034] The microparticle feed for sturgeon fry of the present embodiment is composed of the following components, which are respectively by weight percentage of each component: 50% fish meal, 14% hydrolyzed fish protein, 14% yeast powder, 5% wheat flour, and 5% amylose , fish oil 6%, choline chloride 0.2%, lysine 0.7%, methionine 0.3%, betaine 1%, protease 0.2%, lipase 0.4%, aquatic special multivitamin 2%, aquatic special multi mineral 1.2% .

[0035] 2. Processing steps:

[0036] 1) Weigh various raw materials according to the weight percentage of each component;

[0037] 2) Mix the weighed raw materials for the first time, the mixing time is 80-100 seconds, and make coarse powder after mixing, and the fineness of the coarse powder is required to pass through a 2.5mm sieve;

[0038] 3) Superfine grinding

[0039] According to the characteristics of digestion and absorption of sturgeon seedlings, the functional components in the sturgeon micropart...

Embodiment 2

[0054] 1. Feed formula

[0055] The microparticle feed for sturgeon fry of the present embodiment is composed of the following components, which are respectively by weight percentage of each component: 55% fish meal, 12% hydrolyzed fish protein, 10% yeast powder, 8% wheat flour, and 4% amylose , fish oil 5%, choline chloride 0.1%, lysine 0.5%, methionine 0.5%, betaine 1%, protease 0.2%, lipase 0.3%, aquatic special multivitamin 1.8%, aquatic special multi mineral 1.6% .

[0056] 2. Production steps:

[0057] 1) Weigh various raw materials according to the weight percentage of each component;

[0058] 2) Mix the weighed raw materials for the first time. The mixing time is 80-100 seconds. After mixing, make coarse powder. The fineness of the coarse powder is required to pass through a 2.5mm sieve;

[0059]3) Superfine grinding of raw materials

[0060] According to the characteristics of digestion and absorption of sturgeon seedlings, the functional components in the sturgeo...

Embodiment 3

[0075] 1. Feed formula

[0076] The microparticle feed for sturgeon fry of the present embodiment is composed of the following components, which are respectively by weight percentage of each component: 58% fish meal, 10% hydrolyzed fish protein, 10% yeast powder, 10% wheat flour, and 3% amylose , fish oil 5%, choline chloride 0.1%, lysine 0.2%, methionine 0.2%, betaine 1.2%, protease 0.1%, lipase 0.2%, aquatic special multivitamin 1%, aquatic special multi mineral 1% .

[0077] 2. Production steps:

[0078] 1) Weigh various raw materials according to the weight percentage of each component;

[0079] 2) Mix the weighed raw materials for the first time, the mixing time is 80-100 seconds, and make coarse powder after mixing, and the fineness of the coarse powder is required to pass through a 2.5mm sieve;

[0080] 3) Superfine grinding of raw materials

[0081] According to the characteristics of digestion and absorption of sturgeon seedlings, the functional components in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com