Motor control device

A technology for control devices and electric motors, applied in the direction of electronic commutation motor control, single motor speed/torque control, current controller, etc., can solve problems such as increased vibration and noise, deterioration of efficiency, and out of step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Embodiments of the present invention will be described below with reference to the drawings. In the following description, the same components are given the same reference numerals. Their names and functions are also the same. Therefore, detailed descriptions of them will not be repeated.

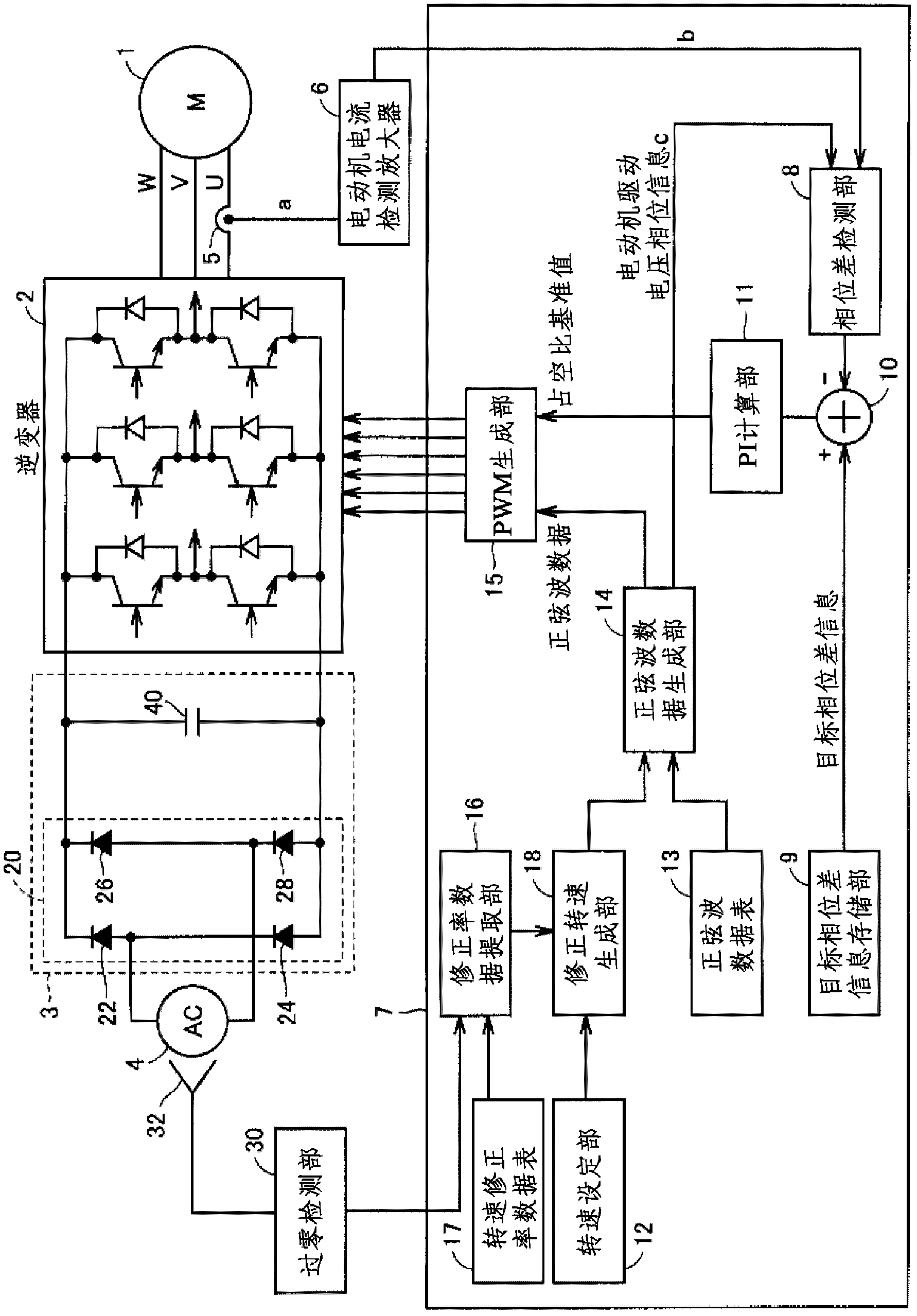

[0062]use figure 1 , a block diagram of a motor control device according to an embodiment of the present invention will be described.

[0063] refer to figure 1 , The motor control device includes: synchronous motor 1, the stator is provided with multi-phase (three-phase) coils, and the rotor is provided with permanent magnets; inverter 2; conversion circuit 3; AC power supply 4; current sensor 5; motor current detection amplifier 6; A zero-cross detection unit 30; a voltage sensor 32; and a controller 7 as a microcomputer.

[0064] Synchronous motor 1 is driven by inverter 2 , and DC voltage obtained by converting AC voltage from AC power supply 4 is supplied to inverter 2 fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com