voice coil motor

A voice coil motor and coil technology, applied in installation, optics, instruments, etc., can solve the problems of material waste, time-consuming and labor-intensive, multiple rework, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The voice coil motor provided by the technical solution will be described in detail below with reference to the accompanying drawings and specific embodiments.

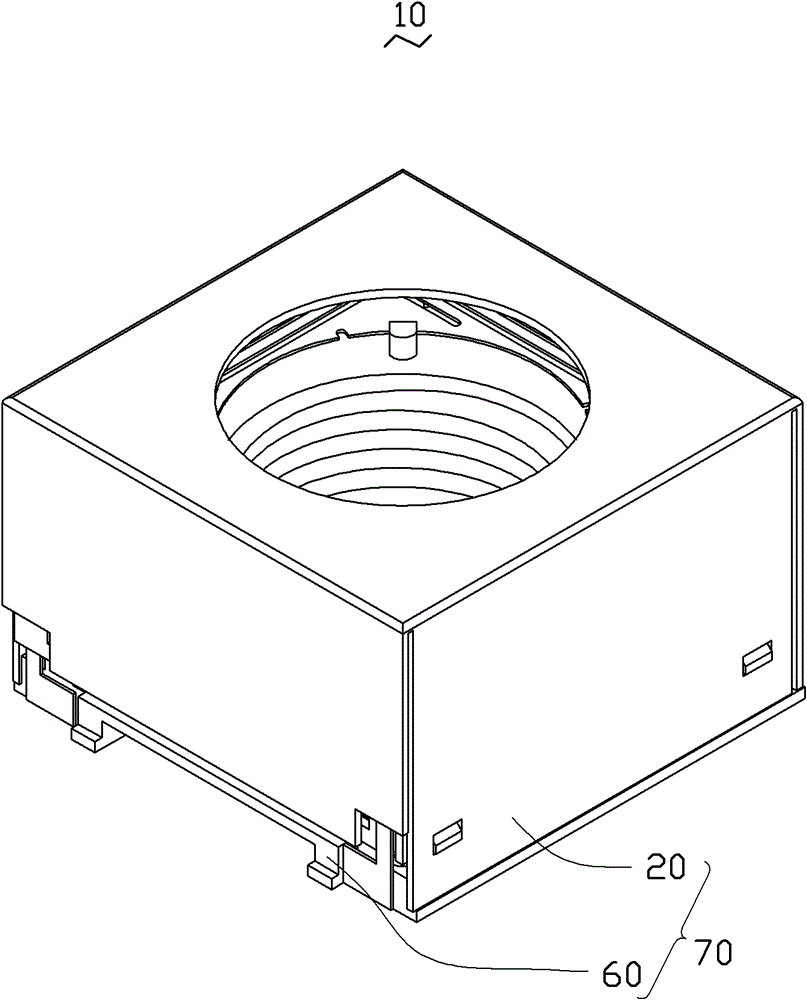

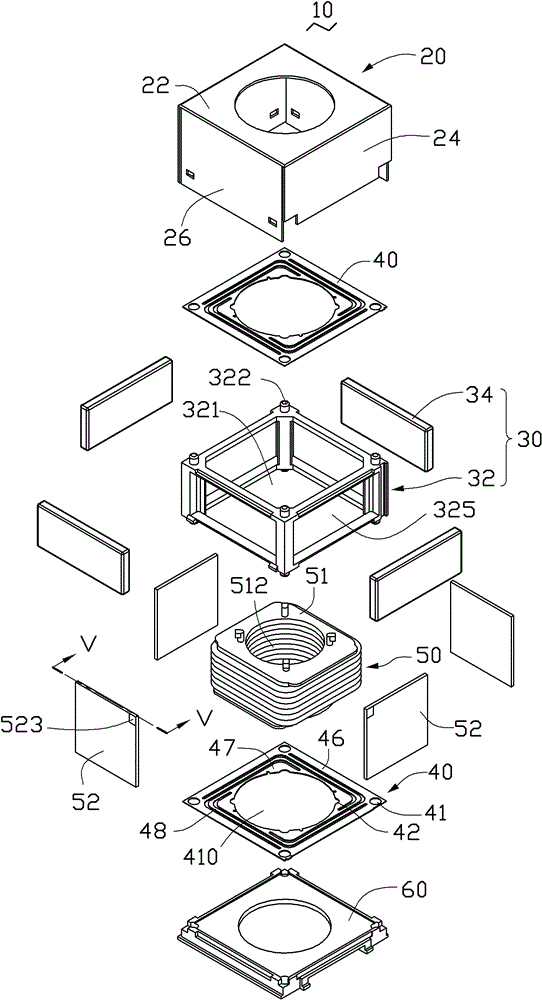

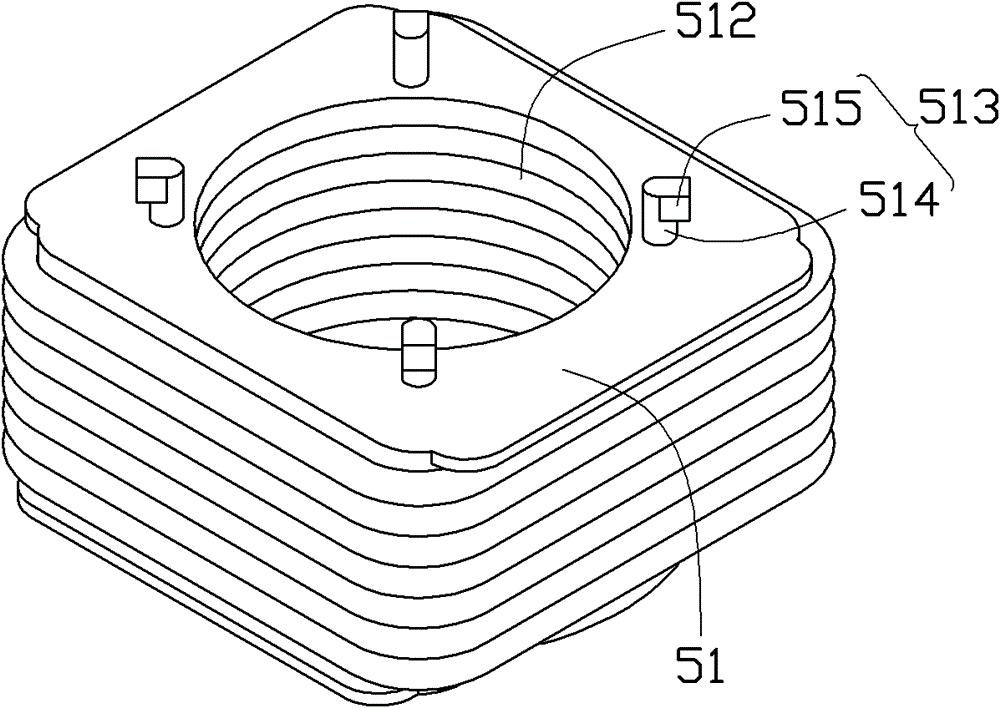

[0046] see figure 1 and figure 2 , the voice coil motor 10 provided by the embodiment of the present invention includes an isolation box 70 , a fixed assembly 30 , two elastic pieces 40 and a movable assembly 50 .

[0047] The isolation box 70 is used to eliminate external electromagnetic interference to the voice coil motor 10 and prevent the electromagnetic interference of the voice coil motor 10 from affecting the operation of its external electronic components. The isolation box 70 includes a housing 20 and a base 60 . The housing 20 can be made of magnetic shielding materials such as nickel-iron alloy, conductive plastic, surface conductive material, and conductive glass. The housing 20 has a quadrangular bottom plate 22 , two first side plates 24 respectively disposed on opposite sides of the bottom p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com