Spot testing method for light emitting diode chip

A technology of light-emitting diodes and chips, which is applied in semiconductor/solid-state device testing/measurement, semiconductor devices, electrical components, etc., can solve the problems of low spot measurement efficiency of LED chip testing machines, affecting the production capacity of light-emitting diodes, etc., and achieve saving optical parameters The effect of testing time, reducing production costs, and improving machine productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention. It should be noted that, as long as there is no conflict, each embodiment and each feature in each embodiment of the present invention can be combined with each other, and the formed technical solutions are all within the protection scope of the present invention.

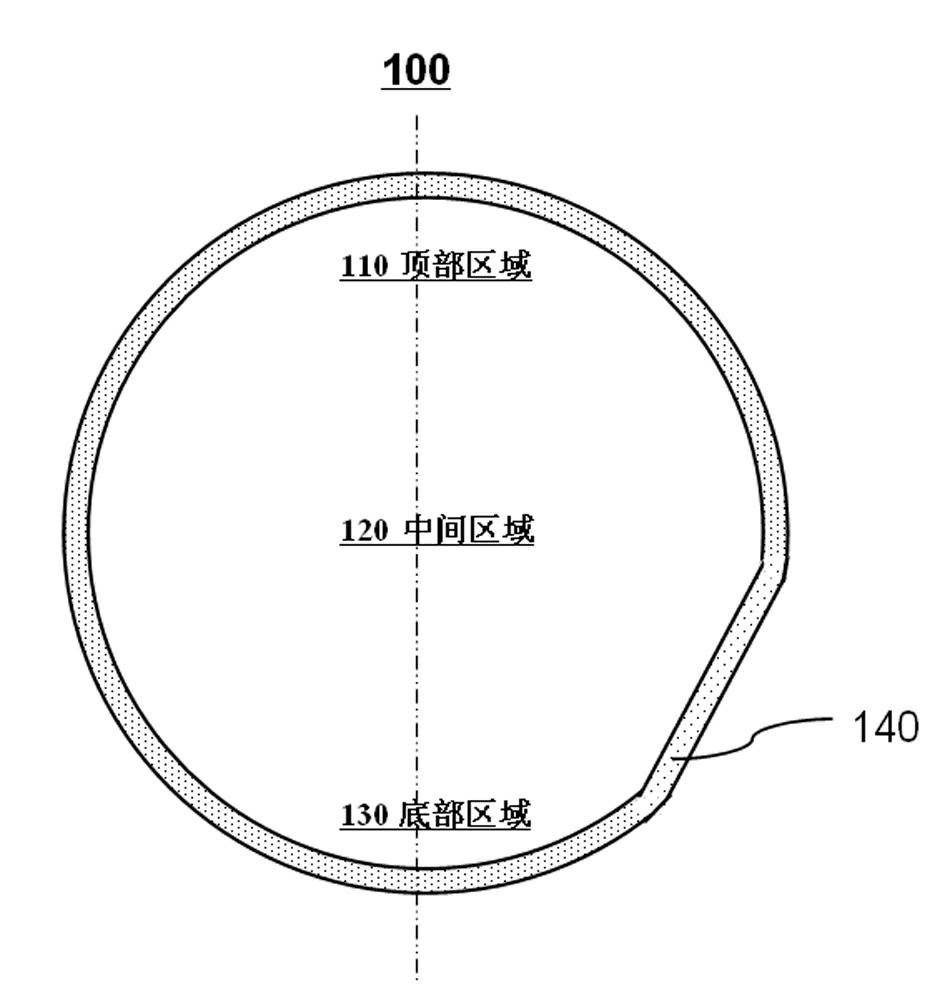

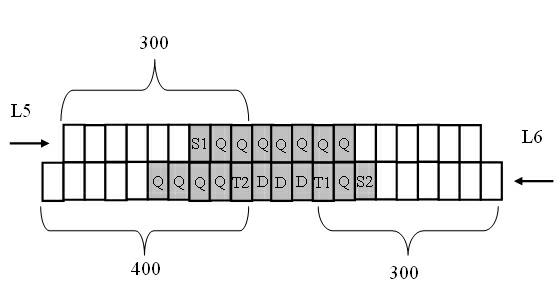

[0026] The following is to distinguish the full test method of the photoelectric parameters of the existing LED chips, and the test method of the full test of the photoelectric parameters and the single test of the electrical parameters is called the new spot test method. Unless otherwise specified in the full text, the new point measurement method refers to the combination of full measurement of photoelectri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com