Co-wound high-voltage and low-voltage coil of transformer and winding method of co-wound high-voltage and low-voltage coil

A low-voltage coil and winding method technology, which is applied in the field of transformers, can solve the problems of high and low voltage coils with complicated procedures and low precision, and achieve the effects of improving heat dissipation, improving product quality, and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

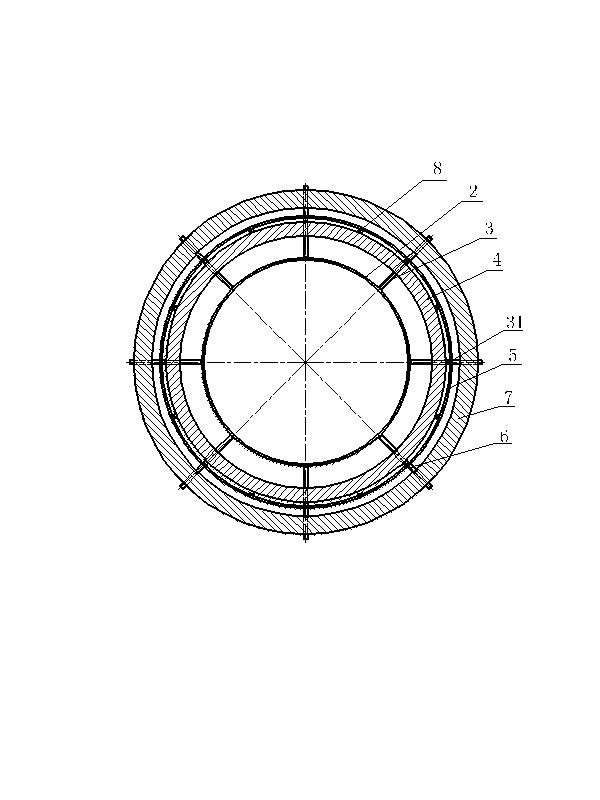

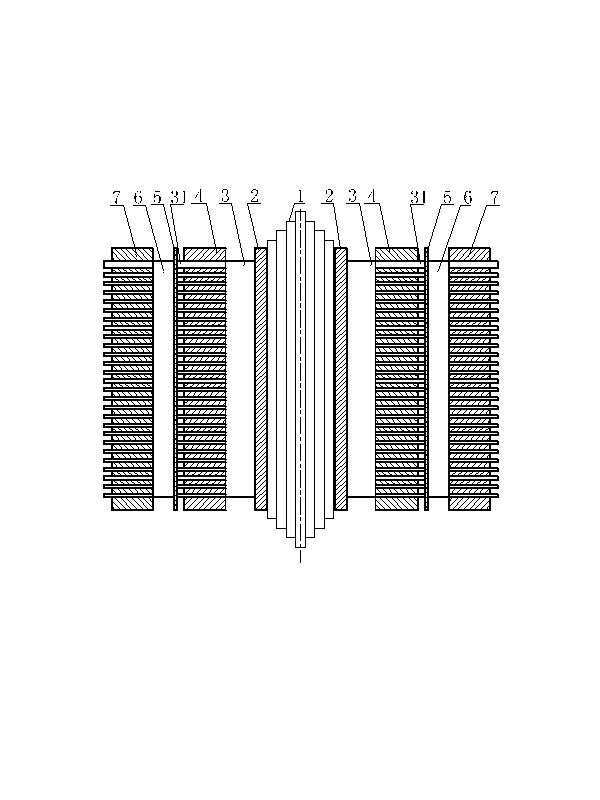

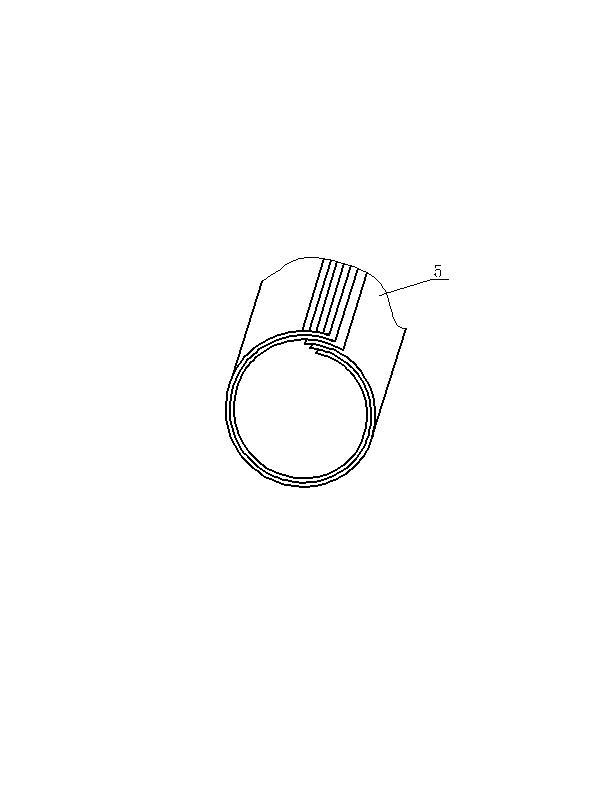

[0026] see figure 1 , figure 2 and image 3 , the high-voltage and low-voltage combined winding coil of the transformer of the present invention includes an iron core 1, a high-voltage insulating cylinder 2 arranged outside the iron core 1, and the outer surface of the high-voltage insulating cylinder 2 is provided with 8 evenly arranged high-voltage coil stays 3 , in this embodiment, the stay 3 is a comb-shaped stay, and a high-voltage coil 4 is wound outside the high-voltage coil stay 3, and the high-voltage coil stay 3 has a certain height protruding from the high-voltage coil 4 The protruding end 31, in the present embodiment, its height is selected as 5mm; a low-voltage soft paper tube 5 is arranged outside the protruding end 31 of the high-voltage coil stay, see image 3 , the low-pressure soft paper tube 5 is formed by stacking several sheets of insulating paper whose ends are staggered by a certain distance (preferably 10-15 mm) and rolled into a tube. In order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com