Tension-resistant high-temperature resistant irradiation cross-linked polyolefin insulated photovoltaic cable

A cross-linked polyolefin, photovoltaic cable technology, applied in the field of power cables, can solve the problems affecting the service life of cables, damage to the cable insulation, fire personnel, etc., and achieves uniform sheath thickness, high temperature resistance, and large current capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

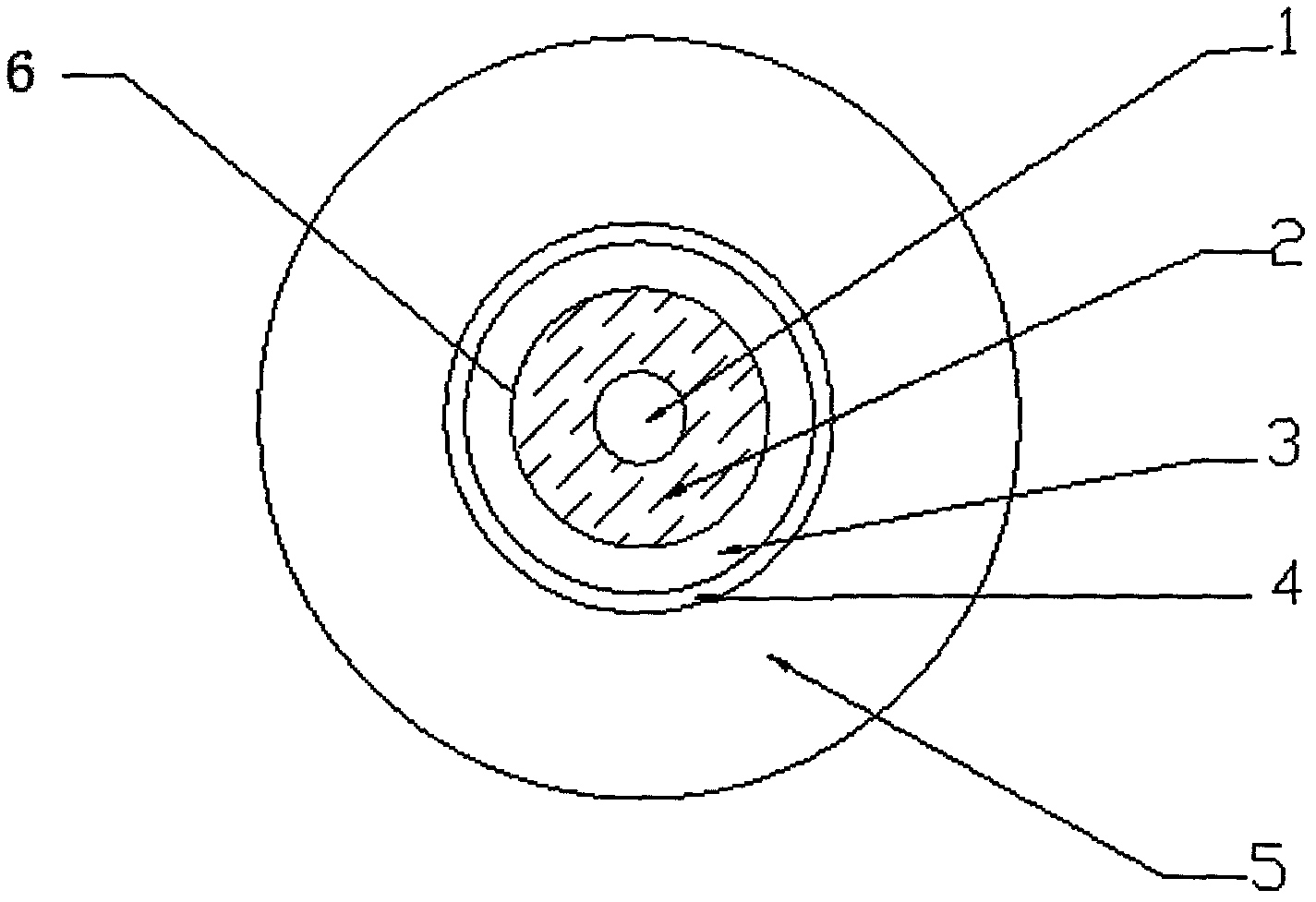

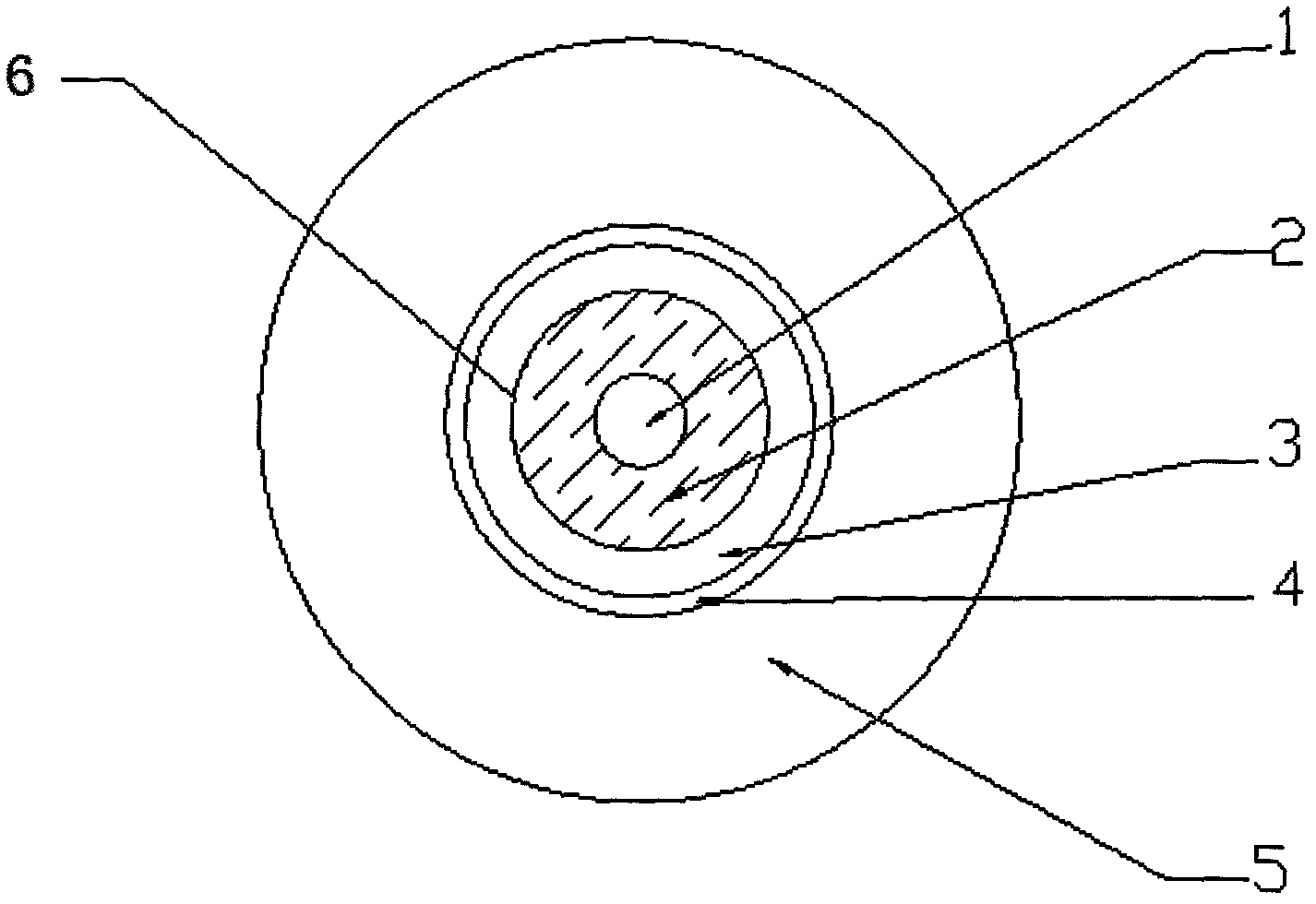

[0026] see figure 1 , figure 1 Schematic diagram of the cross-linked polyolefin insulated photovoltaic cable for tensile and high temperature radiation resistance.

[0027] The tensile and high temperature radiation resistant cross-linked polyolefin insulated photovoltaic cable includes copper conductor 2, tensile element 1, high temperature resistant structure layer 6, low-smoke and halogen-free radiation cross-linked flame-retardant polyolefin insulation layer 3, low-smoke and no-halogen Halogen-resistant high-temperature isolation layer 4 and low-smoke and halogen-free radiation cross-linked flame-retardant polyolefin sheath layer 5 .

[0028] The tensile element 1 is an alkali-free glass fiber high-temperature-resistant filling rope, and the copper conductor 2 and the alkali-free glass fiber high-temperature-resistant filling rope are tightly twisted together to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com